They contacted us asking for help with an application they were looking to undertake. They were working on a test rig for customer’s new container-filling process which would need a high viscosity transfer pump to deliver a non-Newtonian fluid via a nozzle. The liquid would be a polymer with a potential at-rest viscosity of over 100,000cps.

To put this in perspective, a viscosity of over 100,000 cps or centipoise would be an extremely thick, paste-like material that flows very slowly or doesn’t pour at all at room temperature.

By comparison, water has a viscosity of 1cps, brushable silicone rubber has a viscosity of 100,000 to 150,000cps and peanut butter is 250,000cps.

What is a test rig pump?

It’s an essential piece of kit used for testing components under specific pressures, flows and other conditions to evaluate their performance, reliability and integrity.

Test rigs and the pumps inside them are widely used in research and development for testing new equipment, fuels or fluids. They also enable the controlled and precise testing of equipment and components like hydraulic pumps, motors and cylinders to ensure they meet industry standards.

They’re used in various applications from quality control and manufacturing to research and development, plus a variety of educational purposes.

In short, test rigs allow a wide range of tests that can be carried out on small-scale plant before the full-scale rig is built. Test rigs are used for:

- Performance evaluation – they enable the measurement of pressure, flow rate, torque and temperature under various loads to verify that components are working as designed

- Component testing – tests can be caried out on a wide range of industrial equipment including hydraulic pumps, motors, cylinders and valves

- Research and development – test rigs function as proof-of-concept pilot plant for new equipment or fuels, allowing engineers to test limits and optimise designs before scaling up to full production

- Quality control – manufacturers use test rigs for quality control to make sure products meet rigorous safety and performance checks before they go to market

- Educational demonstrations – they help students and professionals understand advanced engineering principles such as fluid dynamics by providing hands-on experience on a small scale

What is a non-Newton fluid?

Its a fluid whose viscosity changes when stress is applied to it.

Newtonian fluids like water flow at a constant viscosity regardless of force. However, a non-Newtonian fluid can act like a liquid or a solid depending on the pressure or stress it undergoes.

So non-Newtonian fluids all have the same characteristics:

- Altered viscosity – Their viscosity is not constant and depends on the amount of force, or shear rate applied to them

- Multiple states – Due to their changing viscosity, they can switch between behaving like a solid and a liquid

- Non-Newtonian behaviour – They do not follow Newton’s Law of Viscosity which applies to simpler fluids like water where viscosity is constant regardless of stress applied

- Complex internal structure – This unusual behaviour is caused by the presence of complex macromolecules or particles within the fluid that rearrange when the fluid is agitated

- Damaged by high shear – Some of these fluids can be irretrievably damaged or degraded by vigorous pumping or stirring, as excessive shear stress can cause separation of components. These are known as shear-sensitive fluids.

What are shear-sensitive fluids?

These are a type of non-Newtonian fluid whose viscosity changes depending on the amount of shear stress applied. There are two types of shear-sensitive fluids:

Shear-thinning fluids become less viscous when agitated or when stress is applied. For example, ketchup, shampoo and mayonnaise are shear-thinning fluids that becomes more liquid-like and easier to pour after being shaken or squeezed. Paint is another example – thick in the tin but thins out when brushed or rolled.

Shear-thickening fluids become more viscous when subjected to stress. For example, Oobleck is a non-Newtonian fluid made up of starch suspended in water. It feels like a liquid when stirred slowly but becomes hard and rubbery when punched.

In addition, the synovial fluid in your joints acts as a shear-thickening fluid, becoming thicker and providing cushioning when your joint is bumped.

A tricky specification

After talking to the client, we started to look at various test rig pump options for the high viscosity mixtures.

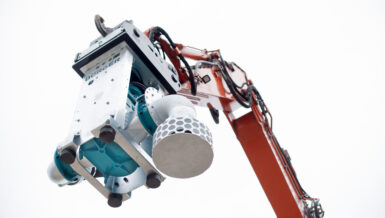

Auger Feed Screw in HopperThe problem we faced was that the viscosity of the liquids would be very high. This meant that there was in danger of forming a clog at the pump inlet due to the liquid’s inability to flow. As a result, the pump would potentially need feeding with fluid which reduced the number of options available to us.

After further discussions with the client, we decided that a non-pulsating flow would be required, meaning that the obvious choice was a wide throat progressing cavity pump with a hopper.

A variety of viscosities

In this application, the client would be pumping a variety of shear-thinning liquids with a viscosity range between 10,000cps and 100,000cps. Some of these liquids would flow relatively easily, whilst others would need a little help. These fluids would be mixed from powder to the client’s own concentrations to test various parameters.

They basically wanted an all-in-one, easy-to-control new pump which would deliver fluids at the same pressure – regardless of the viscosity. In addition, they had various specific requirements they wanted to consider which included:

- A motor speed controller with infinite speed control from 0 to maximum

- A flow rate meter

- A pressure sensor with gauge to protect the motor from running dry

- Inlet/outlet sizes and connection fittings

- A separate control panel incorporating the motor speed controller, flow rate meter and pressure sensor to protect the motor from running dry if possible

- A pump fluid-damping capability

- Polished or specialised internal surfaces on the pump for easy cleaning

What’s more, as the liquids would be over 100,000 cst but shear thinning, this meant we had to install a hopper at the inlet of the pump. The hopper would produce the shear thinning effect by agitating the fluid which would reduce its viscosity. This process would also ensure that the pump head was kept flooded with liquid.

For clarity, it’s worth noting that centipoise or cps, and centistokes or cst, aren’t the same they’re units for measuring different types of viscosity.

Cps measures dynamic or absolute viscosity which is the fluid’s internal resistance to flow from an external force. Cst measures kinematic viscosity which is a fluid’s resistance to flow under gravity and is a ratio of its dynamic viscosity to its density.

Stainless steel construction

To ensure that the different fluid mixtures didn’t corrode internal pump parts the wide throat pump was made from stainless steel. This also made cleaning much easier.

In addition, the shear-thinning transfer pump was fitted with a seal quench to keep the seal faces free from debris which might encounter with particles. This would also provide limited protection if the pump was ever dry running.

As well as the seal quench a probe was wired into the stator which would also to protect the pump from dry running. The probe works by sensing when the stator temperature goes much higher than a normal operating temperature.

Specially designed motor

As the motor was located under the large hopper, the client wanted to be able to adjust the speed and direction of rotation remotely.

This meant that we had to create a special motor which we supplied complete with remote control operation as well as a Bluetooth module to control the shear-thinning transfer pump via an app.

We designed the pump to operate at between 15rpm and 165rpm providing a flow rate of 6L/min to 76L/min at up to 8.5 bar.

Pressure readings

To enable the client to measure pressure, the high viscosity transfer pump was also supplied with a solid-handling diaphragm pressure transmitter. This measures the pressure of fluids which are viscous, may contain solids or form plugs around traditional pressure transducers all of which can lead to unreliable pressure readings.

The diaphragm pressure transmitter was filled with inert silicone oil. As the diaphragm is compressed a pressure reading between 4mA and 20mA gives the level of pressure experienced by the transmitter within a defined range between 0 and16 bar.

As this was an all-in-one solution, we also provided a high viscosity stainless steel industrial flowmeter with a removable display and pulsed output for flow monitoring.

When handling high viscosity liquids, flowmeters need to be able to deal with this by using special high viscosity rotors. These enable the highly viscous liquids to pass through the meter, be recorded accurately and prevent the rotors from becoming clogged.

At North Ridge Pumps we have over 25 years’ successful trading, we have the expertise to select the best pump for every application and project brief offering the optimum long-term option.

If you have an application involving the transfer of particularly viscous or abrasive fluids, get in touch with North Ridge Pumps to see how we can help.