Building on 15 years of collaboration, CAESB brought Danfoss even closer with a tailored service program designed specifically for the demands of their water supply and wastewater infrastructure.

The challenge: Predictable water management

After operating more than 500 drives for over a decade across their integrated water and wastewater operations, CAESB began to face challenges in creating predictability — both in terms of technical uptime and cost. The drives were running under harsh environmental conditions and high mechanical load, which caused some units to show signs of wear and increased the risk of breakdowns. Moreover, with limited tools for predictive maintenance and structured spare parts planning, CAESB also faced difficulties in maintaining full visibility and control over the system.

The solution: DrivePro® maintenance and ultra low-harmonic iC7 drives

Danfoss developed a solution for CAESB rooted in their fundamental belief that effective service must be tailored to each customer’s unique context.

The solution includes DrivePro® Start-up, to secure proper commissioning and long-term performance of newly installed drives. DrivePro® Preventive Maintenance provides custom plans and early fault detection by certified Danfoss experts to keep CAESB’s systems running reliably. The package also includes DrivePro® Spare Parts, ensuring fast access to original components precisely matched to CAESB’s drives for seamless replacement.

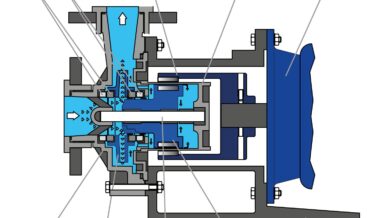

To further reduce downtime, 17 high-power VLT® AQUA Drive FC 202 and several VLT Soft Starter MCD 600 units were refurbished as part of a corrective maintenance solution — a service element added specifically to match CAESB’s need for restoring ageing, high-load units critical to operations.

Ultra low-harmonic (ULH) protection

In parallel with the service agreement, CAESB also began upgrading to the next-generation iC7 series ULH drives, also known as AFE — selected specifically to mitigate harmonic distortion, improve power quality, and protect critical infrastructure.

The outcome: More control, less risk

With the two-year tailored service program, CAESB now benefits from reliable, planned maintenance and a guaranteed response time to improve predictability. Refurbished drives and upgraded units have extended the lifetime of their equipment, reduced the risk of downtime, and brought control to both operations and budgets.

Most importantly, CAESB gained peace of mind, knowing their infrastructure is now supported by dependable products and a long-term partner focused on keeping Brazil’s capital running.

“By engaging early and focusing on what truly matters, we were able to design a solution that met CAESB’s specific needs and positioned us as a true partner in their success.”

Tommaso Ercole Marino, Senior Manager Service Delivery at Danfoss Drives.