The finest surfaces for sensitive components

The surface treatment specialist builds vibratory finishing machines that deburr, smooth and polish metal parts. The workpieces come from industries such as medical technology, the automotive industry and jewellery manufacturing, and are often highly sensitive.

To ensure that the surfaces are processed evenly and precisely, the compound – the special fluid used in the vibratory finishing process – must be fed into the machine in exactly the right quantity. This is the only way to reliably achieve the desired quality.

The pump used previously performed this task reliably. But OTEC Präzisionsfinish wanted more: a more modern solution with greater ease of use, better maintainability and future-proof technology – without compromising on precision and robustness.

Overview of the initial situation:

- Application: wet vibratory finishing

- Medium to be metered: Compound (special fluid for the vibratory grinding process)

- Metering quantity: in the range from a few ml/h to several l/h

- Control of the metering pump: Contact operation, via PLC of the vibratory grinding system

Metering pump beta/ X – compact, precise, durable

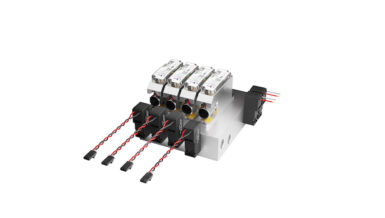

The company now relies on the new diaphragm metering pump beta/ X. The pump meters lubricants with high repeat accuracy (± 1 %) and can be integrated directly into the machine control system via digital signals. Thanks to its robust housing (protection class IP65) and chemical-resistant diaphragm, it is ideal for continuous operation in industrial environments. The built-in stepper motor ensures high precision and consistent metering.

The beta/ X offers an intuitive user interface with a click wheel and display. OTEC Präzisionsfinish uses the pump in contact mode – a precisely defined amount of compound is metered during each machining cycle. The new PFAS-free PE diaphragm was successfully tested in the field at OTEC for over a year before the launch of the beta/ X – without any failures.

Key features of the metering pump:

- Metering range of the beta/ X: 10 ml/h – 50 l/h, with back pressures of 2–16 bar

- Control: digital contact operation

- Metering head and diaphragm: PFAS-free and chemical-resistant

- Chemical-resistant PP housing with IP66 protection, ideally suited for harsh industrial environments

- Operation via click wheel and display: direct input in l/h or ml/contact

Stable processes, shiny workpieces

With the beta/ X, OTEC Präzisionsfinish has taken its metering technology to a whole new level. The pump operates reliably, meters precisely and is easy to maintain. This reduces downtime and increases process reliability – a clear advantage when processing high-quality workpieces.

The collaboration with ProMinent went smoothly: from expert advice and short delivery times to a personal contact who knows exactly what is required. OTEC Präzisionsfinish has relied on ProMinent’s solutions and partnership-based support for many years.

Summary:

- Greater process reliability thanks to precise metering

- Reduced maintenance thanks to robust and PFAS-free diaphragm

- Easy integration into existing control systems

- Ideal for sensitive workpieces with high quality requirements

- Long-standing, trusting partnership with ProMinent