At the same time, updated frameworks such as the Renewable Energy Directive III (RED III) introduced enhanced sustainability requirements and more stringent greenhouse-gas reduction targets for biogas plants.

Against this backdrop, European biogas operators face increasing demand for stable, high-capacity technology capable of processing diverse and challenging substrates. SEEPEX is responding to these requirements by expanding its BTEX and BN pump ranges, providing modern biogas and biomethane facilities with higher throughput, improved premixing, and robust, maintenance-efficient system designs.

EU framework and biomethane potential

As of 2023, combined biogas and biomethane production in the EU is estimated at 22 billion cubic meters, with biomethane alone contributing nearly 5 billion cubic meters — the strongest annual increase ever recorded. Achieving the 35 billion cubic meter target by 2030 requires accelerated expansion of production capacity, simplified permitting, and coordinated investment across the value chain.

Biomethane has a strategic advantage: it is fully renewable and can be injected into existing gas grids. It can support decarbonization of buildings, industry, transport, and electricity generation while reducing exposure to volatile fossil gas markets. The geopolitical situation has amplified these benefits and positioned biomethane as a cornerstone of the EU’s long-term energy security strategy.

SEEPEX technology enables efficient biogas production

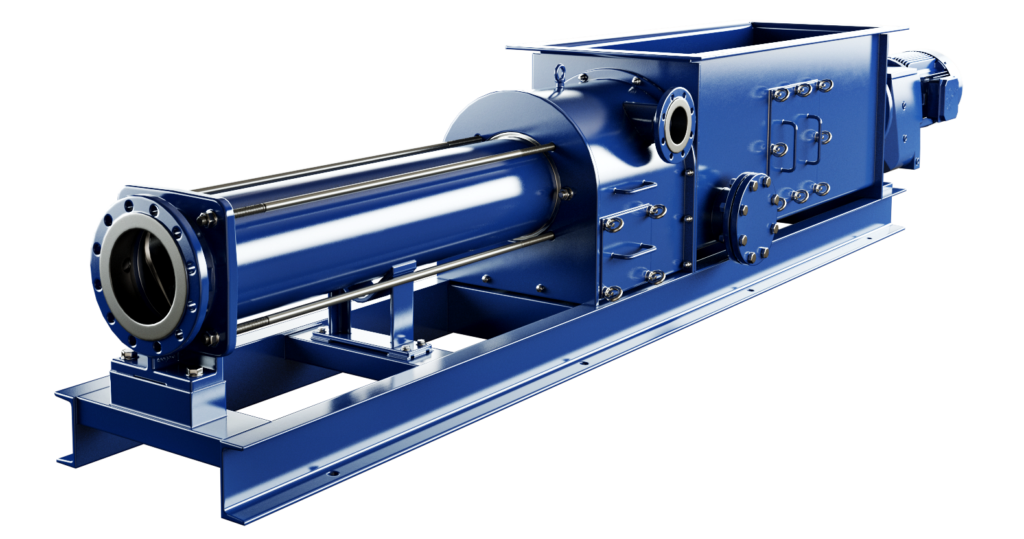

Effective pretreatment and feeding of biomass slurries are essential for maximizing biogas yield. SEEPEX progressive cavity pumps and macerators play a key role in this process. Macerators reduce particle size and increase available surface area, improving microbial digestion. Progressive cavity pumps ensure a constant and controlled flow of pretreated feedstock into the fermenter, supporting stable fermentation conditions and improved gas output.

European biogas facilities face significant challenges when handling fibrous or solid-rich input materials such as high-solid manure, straw, bedding, stones, sand, or wood fragments. These materials can cause heavy wear, blockages or disruptions. SEEPEX mitigates these risks through reinforced materials, optimized hopper and housing geometry, separation zones, and components designed for high abrasiveness.

Maintenance efficiency is equally critical. SEEPEX Easy Maintenance solutions reduce downtime and simplify service interventions. Smart Conveying Technology (SCT), featuring a patented two-piece stator and rotor, allows maintenance without pipeline removal, cutting downtime by up to 85 %. The integrated re-tensioning mechanism compensates for wear and extends component life, lowering operational expenditures. SEEPEX retrofit kits enable cost-effective upgrades of existing equipment.

Robust construction for demanding substrates

European biogas plants frequently process challenging organic materials, including fiber-rich residues, manure with high dry matter content, bedding, sand, stones, or mixed organic waste. SEEPEX designed the BTEX pumps specifically for these substrates.

Their large open hopper and reinforced screw auger ensure dependable substrate intake. The compression housing acts as a solids separator that minimizes entry of abrasive or foreign materials into the pumping chamber. The movable compression housing simplifies maintenance, reducing downtime, while large inspection openings enable quick removal of accumulated foreign objects. Reinforced components withstand abrasive and heavy materials, ensuring reliable operation under harsh conditions.

This durability makes SEEPEX pumps particularly suitable for agricultural digestion systems, industrial pretreatment environments, and municipal biomass streams where continuous operation and service efficiency are essential.

NEW: Expansion with additional BTEX and BN pump sizes

SEEPEX has expanded the BTEX and BN pump ranges to meet rising throughput requirements and evolving substrate conditions across Europe. The new pump size ranges include: 5–20 m³/h, 10–40 m³/h, 20–80 m³/h, and now 40–160 m³/h. With capacities reaching up to 160 m³/h at 4 to 8 bar, these pumps are especially well suited for large volume streams, seasonal loading peaks, or short-term campaign operation.

These performance ranges deliver flexibility for agricultural digesters, industrial co-digestion plants, and municipal waste-to-energy facilities. They are particularly beneficial when combining solid and liquid substrates — for example, co-mixing dry matter with manure before feeding the fermenter. The robust design, optimized premixing performance, and stable conveyance make the new BTEX and BN pumps a highly efficient solution for modern biogas plants in Europe.

Optimized premixing reduces retention time and increases yield

A major advantage of the BTEX pump design is its optimized premixing capability in both the hopper and inlet section. This design enables homogeneous blending of dry, fibrous or high-solid materials with liquids prior to pumping. As a result, sedimentation and the formation of agglomerates are minimized.

This produces several key process improvements:

Operators benefit from more consistent microbial activity, reduced energy usage for internal mixing, shorter retention time in the fermenter, and greater biogas yield. Stable homogenization reduces process disruptions and ensures reliable performance even during periods of variable feedstock availability — a significant advantage for operators striving to maximize energy output and minimize costs.

SEEPEX expertise in practice: Karlskoga Energi

SEEPEX’s advanced pumping technology has proven itself in the biogas sector, as demonstrated by a project with Karlskoga Energi in Sweden. The biogas plant, located approximately 200 kilometers from Stockholm, processes food waste into renewable energy. Initially, three SEEPEX BN 35-12 pumps were installed to convey the highly viscous substrate. After one year, however, increasing wear on the pump components led to higher maintenance costs.

SEEPEX responded by installing a pump monitoring system that recorded real-time data on pressure, speed, and vibration. The data revealed that the issues occurred mainly during weekends, when lower substrate levels in the buffer tanks increased viscosity and caused cavitation. SEEPEX subsequently optimized the substrate mixing process, preventing solids from settling and ensuring more uniform pump operation. The results included longer spare part lifetimes, reduced maintenance costs, and overall lower operating expenses.

SEEPEX’s biogas expertise demonstrates how advanced monitoring technology and process optimization can significantly enhance efficiency in biogas production.

Outlook

With the introduction of the new BTEX and BN pump sizes, SEEPEX positions itself as a key partner for the next generation of European biogas and biomethane facilities. Higher flow capacities, improved substrate preparation, and optimized pump technology enable operators to achieve greater efficiency, stability, and economic performance — particularly when seasonal or campaign-based substrate inputs are involved. The growing importance of biomethane in achieving continental decarbonization and energy security goals makes reliable plant technology more valuable than ever.

Bernd-Guntram Schulz, Product and Market Manager Biogas at SEEPEX, summarizes: “The combination of high flow rates, robust construction, efficient premixing, and maintenance-friendly technology makes the pumps an ideal solution for operators wishing to increase throughput, reduce costs, and run their processes more reliably.”

SEEPEX will continue to support Europe’s transition toward sustainable energy systems with dependable pump technology, engineered solutions, and extensive application expertise.