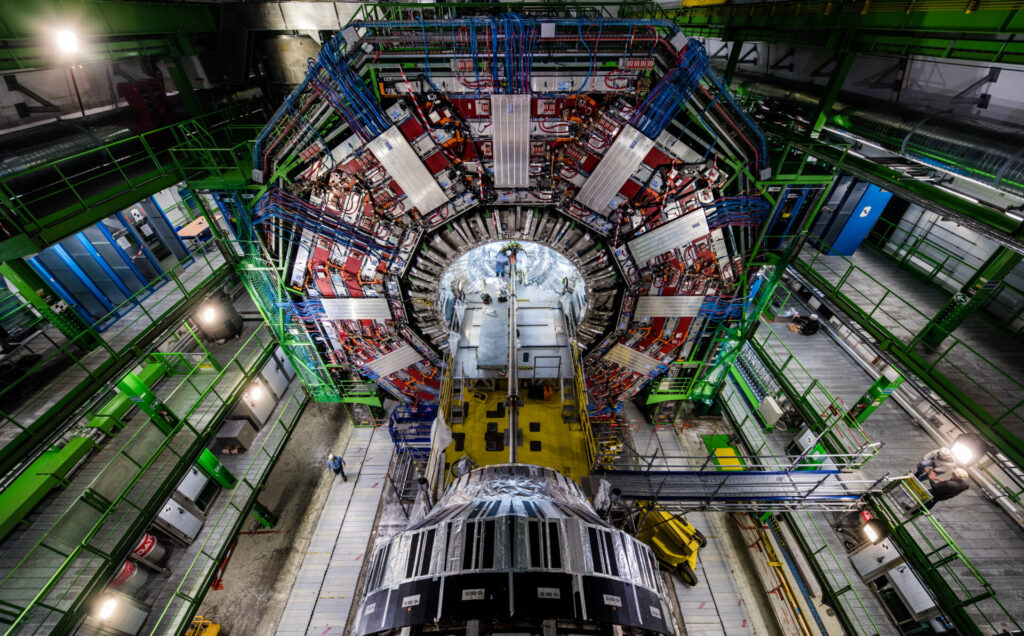

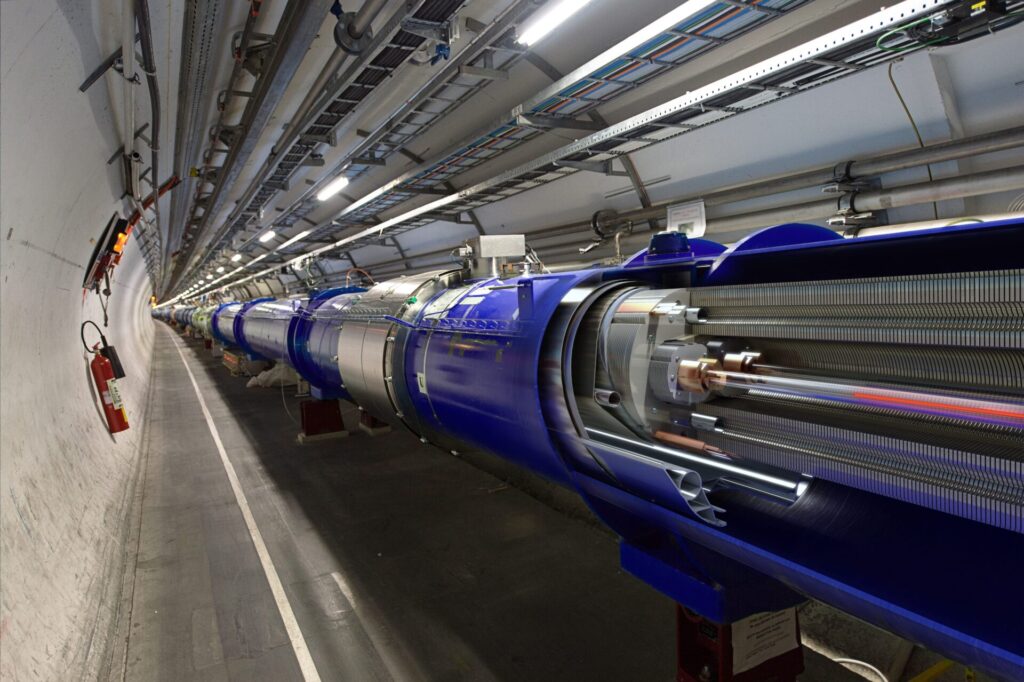

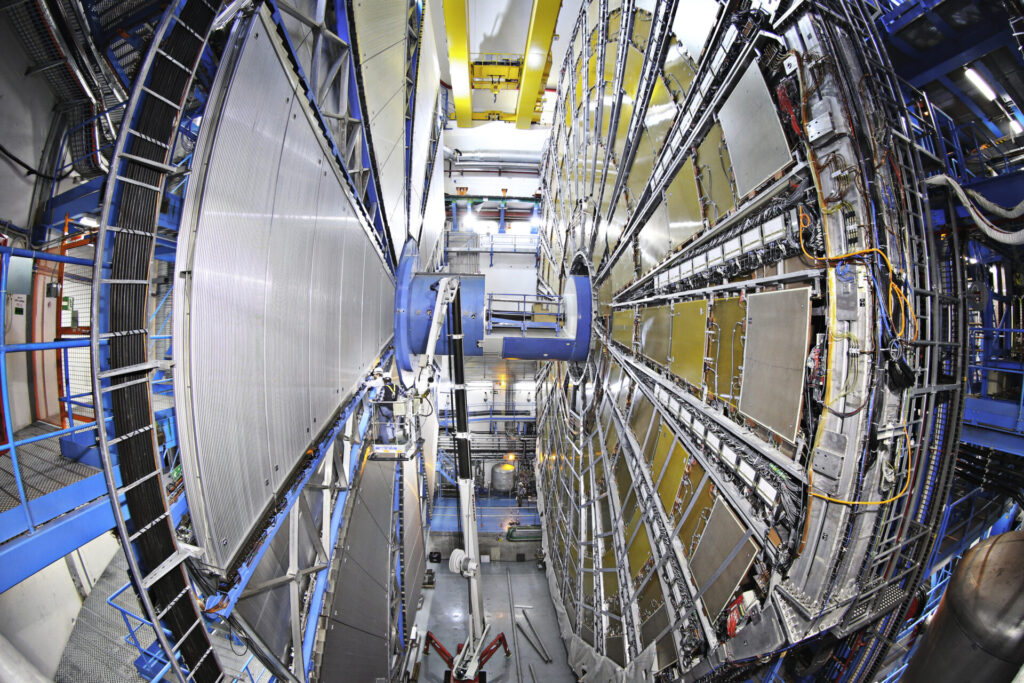

Deep beneath Swiss soil, hidden from the eyes of the world, is a technical marvel of gigantic proportions: the Large Hadron Collider (LHC), the most powerful particle accelerator in the world, is a ring tunnel approximately 27 kilometres long. It is peppered with 4 measuring points, including the ATLAS and CMS detectors. ATLAS is 46 meters long and 25 meters in diameter, making it the LHC’s largest detector, while CMS, weighing 12,500 tons, is the heaviest. For the researchers at CERN, the LHC is a window to the secrets of the universe. To explore the secrets, ATLAS and CMS use precision measurements carried out on the different detection subsystems. They record the path, momentum and energy of the released particles so that they can be individually identified and measured after the accelerated protons collide. The CERN researchers have already proven the existence of the Higgs boson, the “God particle” that gives all other elementary particles their mass.

Precision cooling: Preserving the Integrity of CERN’s Detectors

To ensure that the measurements are precise and the new silicon sensors are not damaged by the high dose of radiation, temperatures as low as -55 °C are required. The electronics and sensors also generate a lot of heat that needs to be dissipated. “ATLAS and CMS will use a two-phase CO2 cooling system for all their silicon trackers and endcap calorimeter detectors, which is an environmentally friendly option compared to other suitable cooling media,” explained Cooling Engineer and CMS Cooling Coordinator Jérôme Daguin from CERN. “The system enables high heat transfer at a low viscosity and a temperature range that is well suited for operating the detector.” To introduce the cooling medium precisely and safely, CERN is once again working with the pump experts from LEWA, whose Swiss subsidiary LEWA Switzerland AG has already supplied pumps for the use of liquid CO2 to other facilities on the research campus.

Prototypes created according to CERN’s own specifications

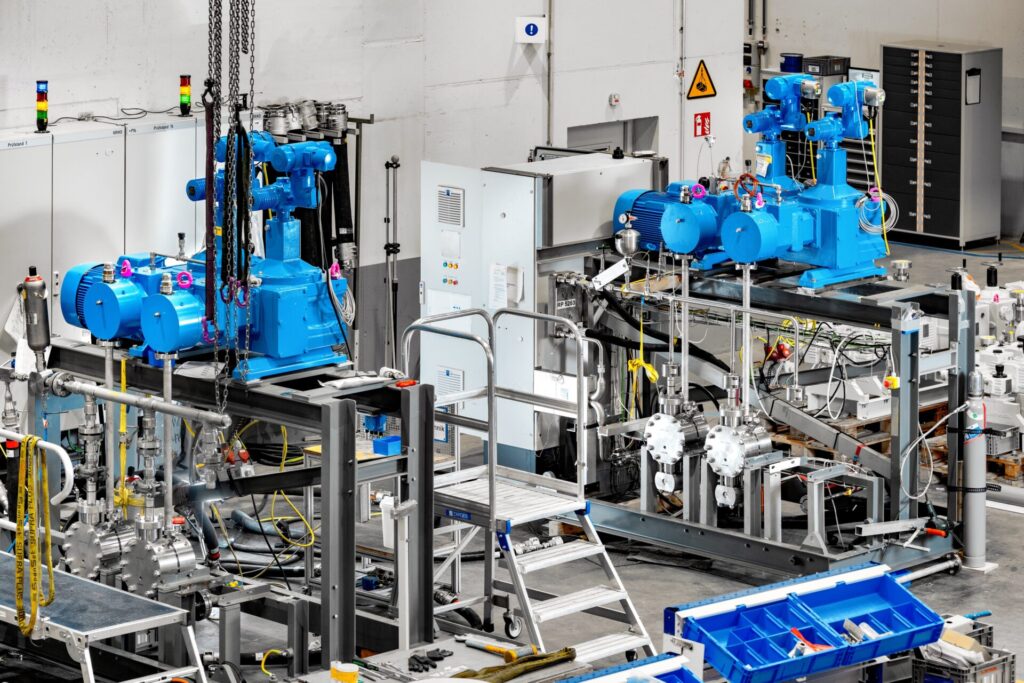

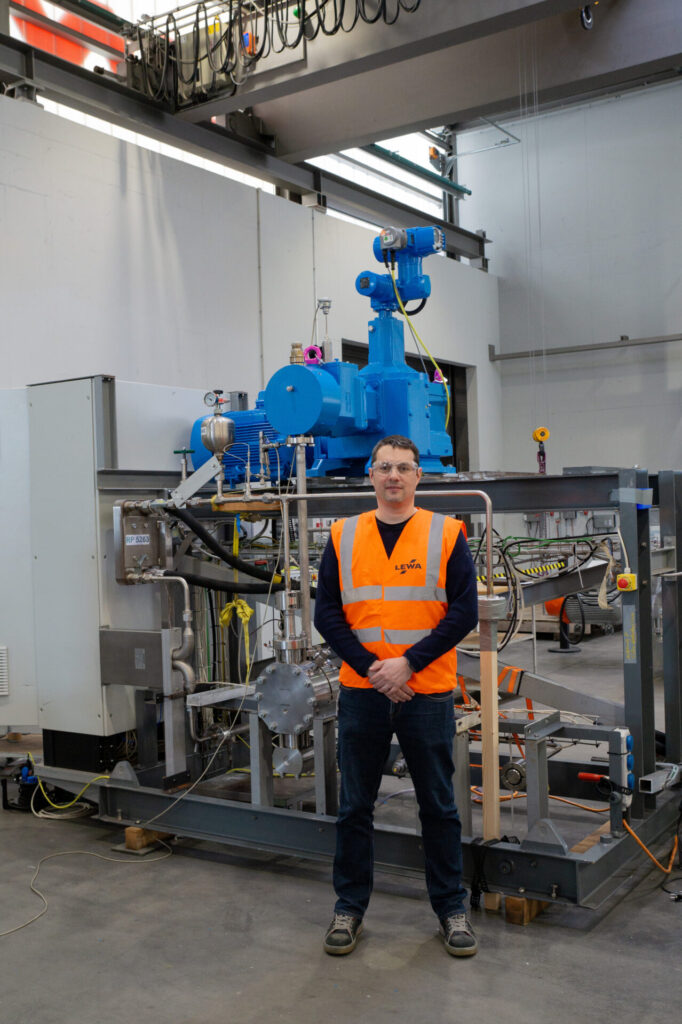

“In this case as well, it was important to be able to implement a robust, durable solution,” explained Wieland Wolff, Area Sales Manager from LEWA Switzerland AG. “Since the drive unit must not come into contact with the extremely low temperatures of the CO2, the pump has a special remote design: the valve head is installed separately from the displacement system of the pump.” Neither CERN nor LEWA wanted to leave anything to chance when it came to ensuring that the sophisticated cooling medium would be transported from the service caverns to the experimental room where the detector is located without any errors. They therefore built several prototypes for the adapted remote version, which functioned as test benches under real conditions under the supervision of CERN employees. They were first tested with water, then cleaned with ethanol and then tested in continuous operation with CO2.

“The list of requirements was quite ambitious and required some very special adjustments which we made during prototype development,” Wolff recalled. For example, to prevent cavitation and thus the loss of the pumps’ full functionality, they must also function perfectly in continuous operation at a speed of 212 rpm against 90 bar. Due to the low temperatures, a special silicone oil is required. For this medium, the existing seals of the basic version were first validated and then replaced by more suitable versions. To prevent the CO2 warning alarms from being triggered accidentally after installation on site, the hermetically tight units were also coated with PTFE at the flange connections and critical points such as the lens gaskets were tested several times during operation. Otherwise, CO2 leaks would result in evacuation and the entire system being stopped. In addition, the drive unit and drive head were modified to provide appropriate measuring points for CERN instruments.

Design adaptations and further development of the diaphragm technology

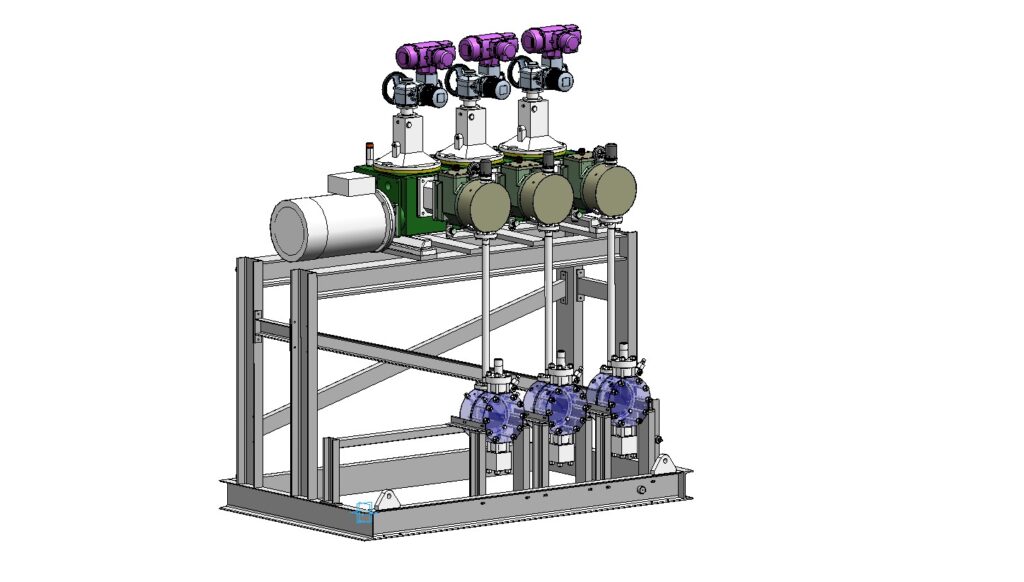

The collaboration has been mutually enriching. Due to the rigorous requirements, LEWA succeeded in improving its existing models designed for low temperatures to such an extent that the lower temperature limit could be shifted further downwards. “For cold temperatures as low as -55 °C, we selected a larger diaphragm pump head so that the deflection of the sandwich diaphragm is smaller,” explained Wolff. This reduces mechanical stress and the risk of cracks or ruptures in the diaphragm, which could otherwise become brittle due to the cold.

Since the cooling medium and the hydraulic oil in the pump head are only separated by the thin PTFE diaphragm, the oil needed to be suitable for low temperatures and not freeze. Furthermore, the forwarded temperature at the drive unit must not fall below -20 °C. To this end, the LEWA engineers added a reciprocating line in which the hydraulic oil can heat up, preventing the -55 °C CO2 from reaching the drive unit. The pipe is designed to minimize compressibility losses and achieve the desired flow rate. In the case of multiple pumps, the hydraulic reservoirs were connected via a manifold and a filter. This is to prevent hydraulic oil vapors from escaping and keep the sensitive silicone oil from aging prematurely due to the humidity in the air.

LEWA pumps drive the new cooling system

The extensive preparatory work since 2018 has paid off for all sides: LEWA has already started customizing and delivering the first batch of a total of 18 LEWA ecoflow LDG pumps for cooling the detectors in the ATLAS and CMS experiments. “They are the core element of the cooling units for the Phase 2 Upgrade silicon detectors of the ATLAS and CMS experiments at CERN,” explained Daguin. “The LEWA pumps are installed away from the detectors in the service caverns, outside the radiation and magnetic field area found in the experimental caverns.” This allows them to be controlled from the control room via electric stroke adjustment and a frequency inverter, eliminating the need for employees to be on site at the pumps. When the current shutdown of the two detectors and the conversion work are completed in 2028, the installed pumps will cool the electronics and the silicon sensors in the detector via a complex network of transfer lines, distribution collectors and small cooling pipes that are in contact with the silicon sensors. For the LEWA pump experts, however, the search for answers has continued: “Together with the experts on site, we want to carry out bending cycle tests that will enable us to fully investigate the service life of the diaphragms in continuous operation. This suggestion came from CERN and underscores the excellent collaboration and our major goal: everyone involved should benefit from the project,” summarized Wolff.

Further information on the internet at: www.lewa.com and www.atlas.cern