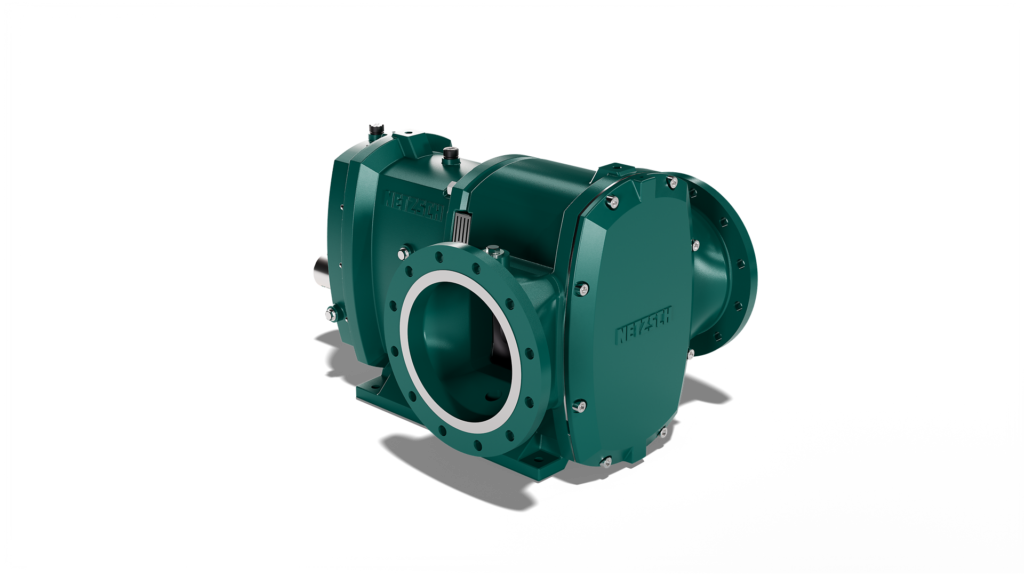

Unveiled at IFAT Brasil 2025, this engineering powerhouse redefines the limits of the NETZSCH pump portfolio and pushes the boundaries of what’s possible in performance and size. The TORNADO® T1 family has grown – bigger, stronger, and unstoppable – welcome to the new era of complex fluid handling.

The TORNADO® T1 XXLB-F is the latest addition to the TORNADO® family, which has long been recognized for its robust construction, reliability, and adaptability to complex fluids. With this new model, NETZSCH introduces a pump capable of handling flow rates up to 1,400m³/h and differential pressures up to 12bar, making it ideal for high-volume, high-pressure applications across a wide range of industries.

Engineering Excellence Meets Application Versatility

What sets the TORNADO® T1 XXLB-F apart is not just its impressive size, but its thoughtful engineering, designed for maximum performance in the most demanding environments.

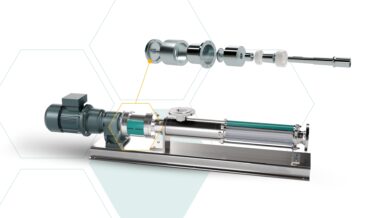

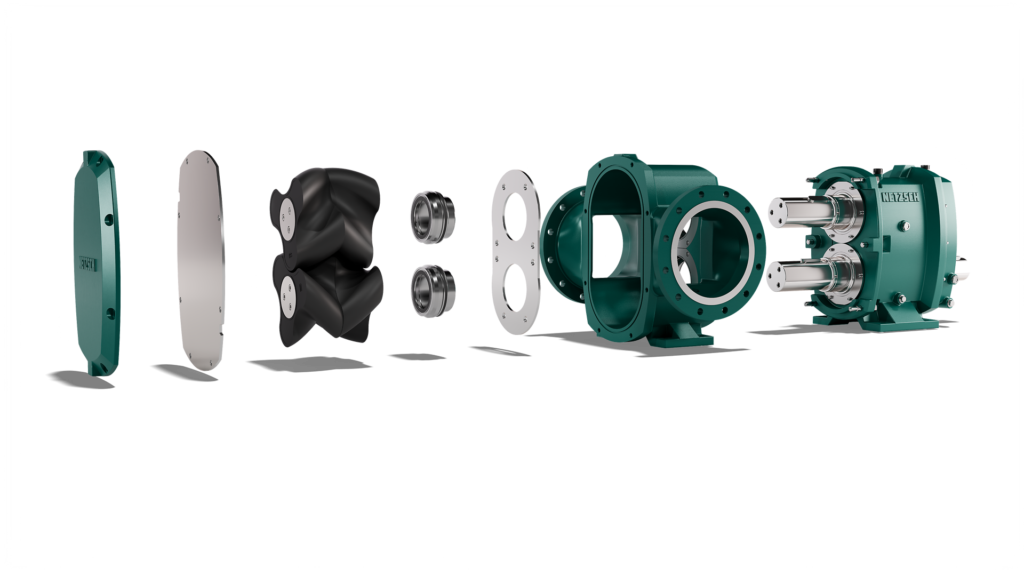

Sealing System – Innovative sealing concepts, from single mechanical seals to double mechanical seals for highly challenging media, ensure optimal process safety and long-term durability. NETZSCH’s proven GSS-Technology (Gearbox Security System) prevents cross-contamination between the pump chamber and gearbox, protecting critical components and enhancing operational safety. Combined with the FSIP® (Full Service in Place) concept, all maintenance tasks can be carried out without removing the pump from the pipeline — saving time, reducing downtime, and lowering maintenance costs.

Helical Lobe Design – Flow-optimized, three-wing helical lobes are individually adapted to the conveyed medium. Both the lobe material and geometry are specifically engineered to meet the exact requirements of each application, ensuring superior wear resistance and extended service life. Special geometries are available for viscous, abrasive, or solids-containing media, guaranteeing reliable performance even under the harshest operating conditions. This tailored approach not only enhances hydraulic efficiency but also reduces energy consumption and maintenance intervals.

Wear Plates – To further extend service life, the XXLB-F is equipped with axial wear plates as standard. These highly wear-resistant plates protect critical pump surfaces and significantly reduce wear in demanding applications. For extremely abrasive media, radial wear plates are available as an optional upgrade, providing additional housing protection. Together, these wear protection measures maximize resistance to abrasion, minimize unplanned downtime, and maintain consistent pumping efficiency over time.

Heavy-Duty Bearing System – Engineered for 24/7 continuous operation, the XXLB-F’s heavy-duty bearing arrangement ensures precise shaft alignment, minimizing mechanical stress and maximizing service life. Designed to withstand high loads, the bearing system delivers the durability needed for solids-laden or highly viscous media. The result is a robust, low maintenance bearing solution that ensures smooth operation and long-term reliability in even the harshest industrial environments.

Ideal choice in demanding applications

When it comes to challenging conveying tasks, the NETZSCH TORNADO® T1 XXLB-F is the solution customers can rely on. It is perfectly designed for all tasks in wastewater treatment.

With its high flow capability and efficiency, the XXLB-F is ideal for MBR (membrane filtration) applications. Also, because of its reverse operation ability to handle both filtration and backwashing in one single unit, it saves space, time, and maintenance effort. MBR plants with centrifugal pumps require two pumps (one for filtration and one for backwashing).

For wellpoint dewatering, the XXLB-F offers unmatched reliability in controlling or lowering groundwater levels, making excavation and construction projects for foundations, tunnels, trenches, and pipelines both safe and efficient.

Our lifting systems, equipped with the FSIP® (Full Service in Place) concept, provide a very compact, service-friendly solution for sewage and drainage systems, minimizing downtime and maximizing productivity.

In the mining sector, the XXLB-F proves its strength by effortlessly removing unwanted water accumulations from mines and pits, ensuring uninterrupted operations. Especially when you consider the space restrictions underground, the XXLB-F, with its extremely tiny footprint, is the best choice, and the full service in place concept is mandatory.

For the oil & gas industry, whether in tank depots, seaport terminals, or petrochemical plants, the XXLB-F stands for robust performance and reliability, features the necessary material properties/variations and complies with the needed standards and certifications such as API.

Even in the most demanding food industry applications, such as conveying highly viscous magma and molasses in sugar production, the XXLB-F demonstrates its endurance — operating at low speeds with high displacement volumes to ensure gentle, efficient conveying without damaging the sugar crystals.

And when it comes to replacing centrifugal pumps, in particular submersible centrifugal pumps, the XXLB-F shows significant advantages: easy service and maintenance thanks to dry installation outside the pit due to self-priming capability. It performs consistently at its high efficiency across a broad flow range and can be maintained without taking the pump out of the sump or the pipeline. Submersible centrifugal pumps, on the other hand, require costly substructures to remove or lift the pump and only reach peak efficiency at one specific operating point. With its full service in place concept, all maintenance parts are front-loading and can be inspected while the pump is still installed in the plant and connected to the pipeline.

The TORNADO® T1 XXLB-F is more than just a pump—it’s a statement of NETZSCH’s commitment to innovation, customer-centric design, and engineering excellence.

With NETZSCH, you’re choosing a partner dedicated to delivering the most reliable, efficient, and tailor-made solution for your application. The XXLB-F is built to handle your toughest challenges with confidence, efficiency, and NETZSCH quality.

Author: Stefan Schöberl,

Global Productline Manager TORNADO® Rotary Lobe Pump

NETZSCH Pumpen & Systeme GmbH

Waldkraiburg