Application

During the production of engine components by injection molding, blowhole inclusions can occur in concealed channels. These cause a narrowing of the channel and can lead to partial or complete blockage. A proper flow of the corresponding medium is no longer guaranteed. Until now, only a single-unit inspection by means of endoscopic measurement was possible. This was very time-consuming and could not be automated, taking into account short cycle times.

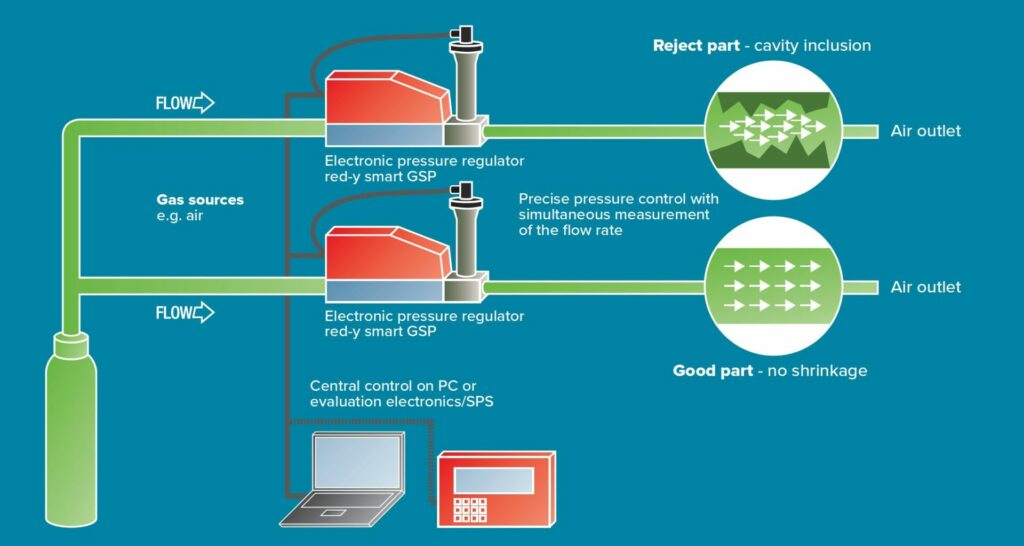

Figure 1: Functional process scheme on the inspection of engine components for blowholes

Challenge

To provide a measuring method that enables the component to be checked for inclusions in the shortest possible cycle times.

Solution

Vögtlin electronic pressure controller with pressure transmitter.

Figure 2: The production of equivalent quality engine components requires perfect flow through the ducts. The red-y smart pressure controller precisely controls the pressure while measuring the flow rate.

With the electronic pressure controller type Vögtlin red-y smart GSP, a given test pressure can be set with simultaneous measurement of flow rate. As a result, the user has a statement about constriction or occlusion of the component. Conform parts can therefore easily and fast be distinguished from inferior parts.

Customer first performs a leak test for the entire system. Good part is determined by endoscopic examination and designated as “master part” for the test. Now the flow rate at test pressure 30 mbar g is determined. This value is used as a guide value for the assessment of the other series parts to be tested.

Left: Good part Right: Bad part

Depending on the size of any shrinkage cavities that may be present, there is a small to significant drop in the flow rate at a constant test pressure. This makes it possible to reliably test cavities/channels that are difficult to access in a cost-effective and effective manner. MEMS technology insures a long-term stability without any drift as long as the gas supply is clean and dry. Dual temperature calibration avoids error caused by ambient and gas temperature better than alternative mass flow controllers.

| Key features | Interfaces |

|---|---|

| ★ Precise and fast control ★ No open/close valves required thanks to tightly sealed control valves ★ High repeatability ★ Real gas calibration / Multiple gases per device ★ High savings possible with mixed gases ★ Independent of temperature and pressure ★ Easy to maintain | ★ Analog ★ Modbus RTU ★ Profibus DP-V0/DP-V1 ★ Profinet ★ EtherCAT ★ Ethernet/IP |