The Gas Control Challenge in Benchtop and Pilot-Scale Bioreactors

Designing gas flow control assemblies for small-scale bioreactors involves a unique set of engineering challenges that go beyond precision alone. These systems must balance performance, integration simplicity, and cost—all within tight spatial and regulatory constraints:

- Dynamic Range Requirements: Gas flow rates must be controlled over several orders of magnitude, from very low flows during seed culture stages to moderate rates in intensified pilot processes.

- Integration Complexity: Traditional gas delivery setups often involve multiple components—MFCs, valves, sensors—from different vendors. This increases the complexity of assembly, raises the risk of leaks, and leads to longer maintenance cycles and potential downtime due to compatibility issues or part failures.

- Footprint Constraints: Benchtop and pilot-scale systems demand compact assemblies that can deliver high performance without consuming valuable instrument space.

- Cost Barriers: High-specification gas control components can be prohibitively expensive for small-scale systems, limiting accessibility and slowing early-stage development.

These challenges make it difficult to design gas control solutions that are both technically robust and commercially viable for early-stage bioprocessing environments.

Industry Trends Impacting Gas Control Needs

Emerging trends in bioprocessing further complicate gas control:

- Process Intensification: Higher cell densities and perfusion systems require more responsive and adaptable gas dosing.

- Single-Use Bioreactors: Disposable systems call for components with minimal contamination risk and easy integration.

- Continuous Manufacturing: Sustained culture processes demand stable gas flow control over extended periods without recalibration.

- Digitalization and PAT (Process Analytical Technology): Real-time monitoring and control increasingly rely on precise, reliable gas flow data for closed-loop feedback.

Any gas control technology aiming to succeed in this environment must be flexible, reliable, and designed with these evolving needs in mind.

Integrated MFC Assembly: A Technical Approach to Overcome Gas Control Challenges

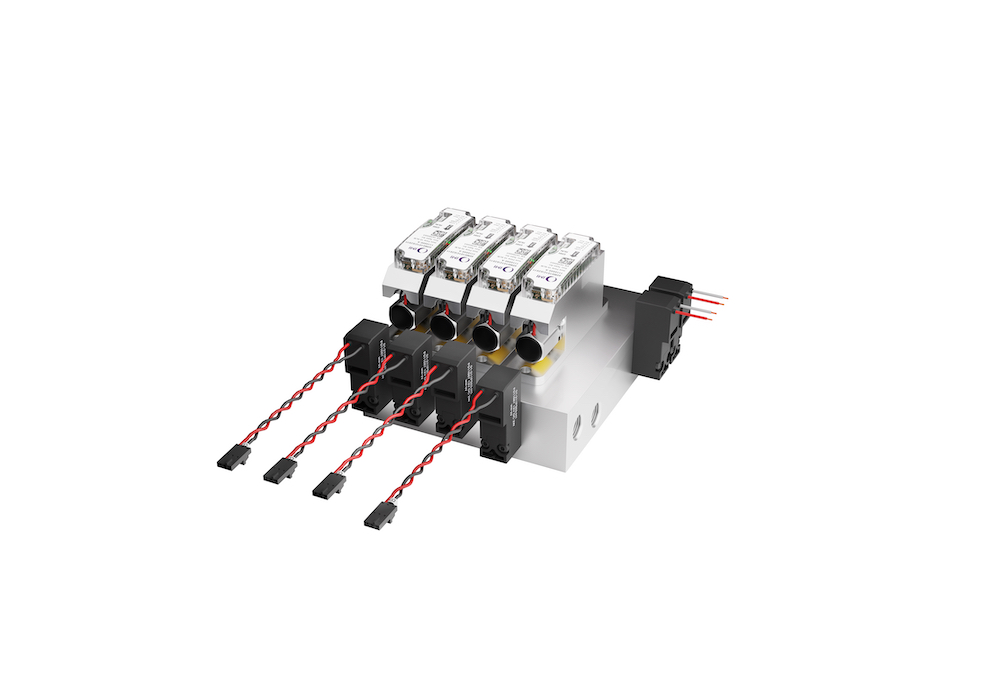

IMI’s integrated Mass Flow Controller (MFC) assembly—combining CHIPREG and/or FLATREG MFCs with miniature valves and a custom aluminum manifold—addresses the critical pain points of bioreactor gas management through:

- Ultra-Compact Format: CHIPREG MFCs are smaller than a matchbox. Mounted directly on a manifold, the integrated assembly saves even more space compared to traditional setups with tubing and fittings—ideal for benchtop and pilot-scale instruments.

- Wide Dynamic Range: With turndown ratios up to 1000:1, the system delivers precise flow control across all bioprocess stages, from low-flow seed cultures to intensified pilot-scale operations.

- Leak Risk Reduction: By removing external tubing, fittings, and multiple connection points, the assembly minimizes leak paths—supporting sterility, reducing maintenance, and improving system uptime.

- Simplified Integration: The plug-and-play design reduces component count and assembly time. Fewer suppliers and parts mean lower cost of ownership, less procurement complexity, and fewer compatibility risks.

- Engineering Efficiency: OEM engineers can focus on advancing instrument performance rather than designing gas control systems from scratch—accelerating development and enabling innovation.

By consolidating multiple functions into a single engineered assembly, this solution tackles integration complexity and supply chain challenges that have traditionally hindered bioreactor gas control systems.

Real-World Impact: From Engineering to Bioprocess

IMI’s integrated MFC assemblies are already in use by bioreactor OEMs, delivering measurable results:

“Your integrated MFC assembly helped us reduce cost by 50%, reduce size by 70%, simplify our supply chain, and increase reliability. It also gave us a scalable gas control architecture we can adapt across multiple instrument formats.”

— Head of Engineering, Bioreactors

This feedback reflects the tangible advantages gained by reducing the number of vendors involved, minimizing assembly footprint, and improving system robustness—while enabling consistent gas control across different instrument platforms.

Why Precision Gas Control Matters: Problem-Solution-Benefit

- Problem: Bioreactors require precise, repeatable gas dosing to maintain critical parameters (DO, pH). Current multi-component setups introduce variability, risk leakage, complicate calibration, and limit scalability.

- Solution: An integrated MFC assembly with wide dynamic range and compact footprint, designed to simplify system integration and maintain consistent performance across scales.

- Benefit: Better control means more reliable batches, better performance across scale, less downtime, and faster instrument development. Fewer parts and suppliers also streamline procurement and reduce total cost of ownership.

Looking Ahead

Bioreactor platforms are evolving—toward higher throughput, modular designs, and deeper digital integration. These shifts demand gas control systems that are more compact, responsive, and automation-ready.

For OEMs, this means building instruments that are easier to assemble, validate, and scale. Integrated MFC assemblies help reduce design complexity, improve reliability, and accelerate development cycles—minimizing delays and maximizing flexibility.

In a competitive landscape where speed and robustness matter more than ever, simplifying gas control isn’t just smart—it’s a strategic advantage.