Other products need to be homogeneous in order for them to remain stable, for example pharmaceutical suspensions such as vaccines, or to help increase the shelf life in products like sauces and flavour emulsions.

When most people think of homogenisation what comes to mind is high pressure homogenisers, which are powerful devices that use a piston pump to force product through a very small adjustable aperture at high pressure. Although these devices can ensure homogeneous products, they require a large amount of energy and capital expenditure.

However, what many people don’t realise is that for the vast majority of products a high pressure homogeniser isn’t actually required. Reducing the globule or particle size down to around 2 – 5 microns is a sufficient degree of homogenisation for products such as creams and ointments, suspensions, etc. A Silverson high shear mixer/homogeniser can achieve a globule or droplet size in this range of and in some cases, depending on the formulation, finer results down to 0.5 microns can also be obtained with a Silverson mixer, eliminating the need for expensive homogenisation equipment in the manufacturing process.

An international food service company recently purchased a Silverson mixer/homogeniser to replace a high pressure homogeniser in one of their processing lines.

The customer was using a conventional powder incorporation system to disperse powdered ingredients into a liquid egg solution. The mixture was then pumped to a large holding tank, then through a homogeniser, before finally being pumped through a heat exchanger to pasteurise it.

The company contacted Silverson to see if it was possible to replace the high pressure homogeniser with a Silverson mixer as a final, single pass before pasteurisation as they had been having problems with lumps which were clogging the equipment and slowing down production.

An on-site trial was arranged and the Silverson mixer was tested in place of the high pressure homogeniser while the rest of the process line and equipment remained the same.

The results of the trial confirmed the Silverson mixer was an excellent replacement for the homogeniser and was able to achieve better results as it eliminated the problematic lumps. The Silverson mixer allowed the product to remain stable and maintained the same shelf life the company had achieved using the homogeniser, but at quicker and more energy efficient rate, reducing processing times and costs. Silverson mixers are also much simpler to operate, maintain and clean.

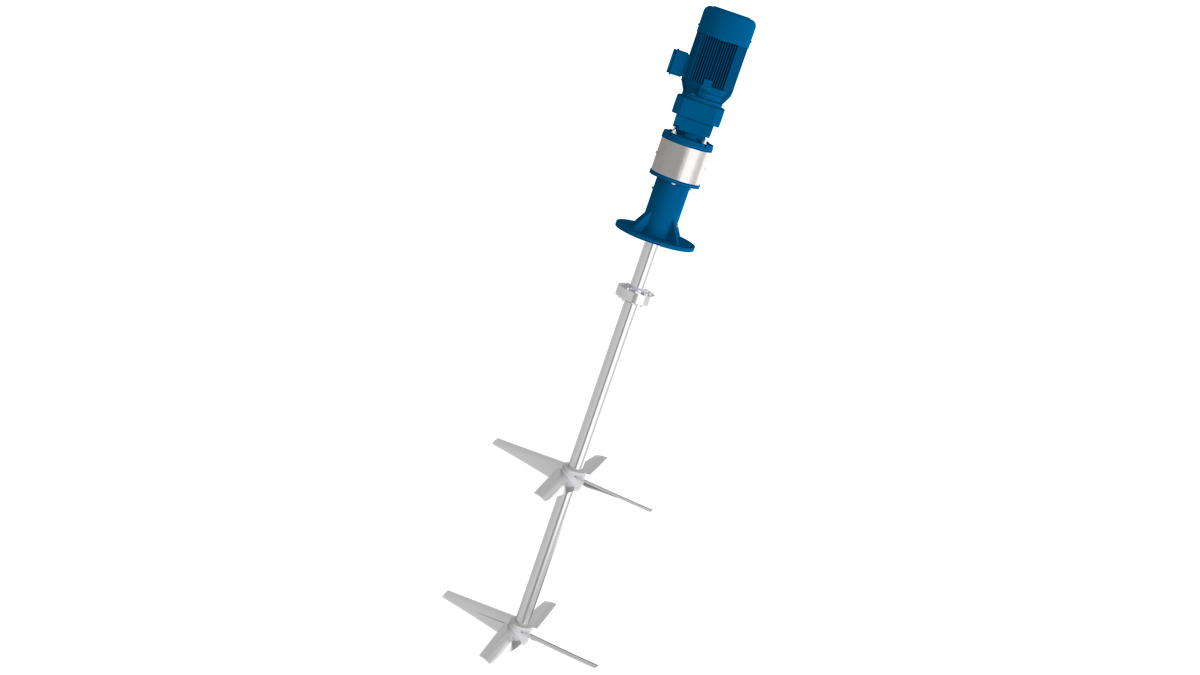

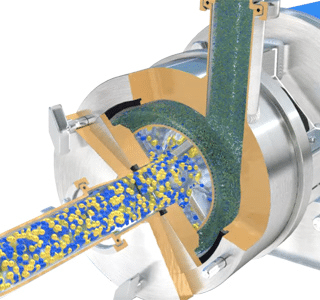

The Silverson mixer was able to achieve this due its precision engineered rotor/stator workhead which generates exceptionally high shear rates in a three stage mixing/homogenising process; firstly the high speed rotor draws materials into the workhead where they are intensely mixed. Centrifugal force then drives the materials to the periphery of the workhead and subjects them to mechanical shear in the precision gap between the rotor and stator. This is followed by intense hydraulic shear, as the product is forced through the stator screen at high velocity and circulated back into the mix. Fresh material is continually drawn into the workhead, progressively reducing globule or particle size and quickly resulting in a homogeneous, uniform product.

Although Silverson mixer/homogenisers can be used for a vast majority of products, there are a small amount of applications where sub-micron size is required, for example the manufacture of flavour emulsions. For these applications that truly demand sub-micron particle size, a high pressure homogeniser would indeed be required.

However, throughput through the high pressure homogeniser can be low, and sometimes more than one pass through the machine may be required, especially where it is being fed with a product with a large or uneven particle or globule size, resulting in long and costly processing times.

This can be overcome by premixing the product with a Silverson mixer. The premix will pass through the high pressure homogeniser at a much higher rate, due to the uniform globule size and this will dramatically improve throughput, process efficiency and operating costs of the high pressure homogeniser.

With over 70 years of mixing experience Silverson has an unmatched level of expertise and has helped thousands of companies meet their unique mixing requirements. So no matter how challenging your application, Silverson mixing experts will work with you to make sure you get the mixer that gives you the results you expect.