Energy use and costs vary by water treatment plant. The cost depends on a number of things, including the region (local energy tariffs and landscape), the type of treatment process, the level of treatment, the size of the treatment plant, and condition of the piping network.

Of all the processes common to water treatment, pumping water into the plant and the distribution system is the most costly. This can represent 15–70 percent of the total energy usage at a water treatment plant, and the water treatment cost can range from 15–50 percent of the overall operating cost.

The Northwest Energy Efficiency Alliance (NEEA) states that ”efficiency is the most cost-effective way to meet our future energy needs,” and facilities can save between 5–20 percent of total energy consumption by installing energy-management systems.

The Northwest Energy Efficiency Alliance (NEEA) states that ”efficiency is the most cost-effective way to meet our future energy needs,” and facilities can save between 5–20 percent of total energy consumption by installing energy-management systems. So, it stands to reason that anything that can be done to materialize the reduction of energy usage and its costs is a win-win scenario. This is not only good for the environment, but for the public’s pocket. As such, proper operation of pumps is a must.

How can you reduce energy consumption at your facility?

The latest generation of ultrasonic pump controllers is capable of enabling significant energy cost savings in a matter of months within water treatment process operations. Ultrasonic controllers support level, volume, pump, and flow control, as well as open-channel monitoring through a full suite of advanced features.

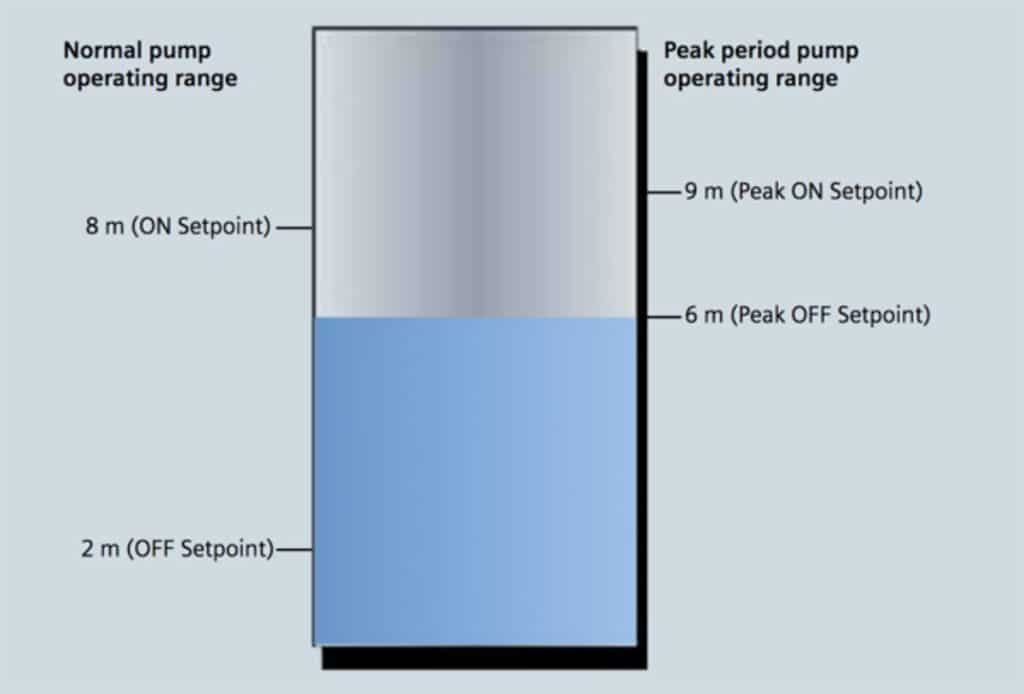

In normal operation, the controller will turn on pumps once water reaches the high level setpoint and begin pumping down to the low-level set point. In contrast, the latest generation of ultrasonic pump controllers will pump wells down to their lowest level before the premium rate period starts, thereby maximizing the well’s storage capacity. The controller then maintains a higher level during the tariff period by using the storage capacity of the collection network. Pumping in this way ensures compliance with environmental regulations and minimizes energy use in peak tariff periods.

Another cost-saving feature of using modern ultrasonic controller for pump control in water treatment processes is infiltration and ingress monitoring. In a closed collection network, it is inefficient and costly to pump rainwater entering the system due to leakages from degraded pipes. Today’s ultrasonic controllers are capable of calculating pumped volumes and providing useful historical trending information for detecting abnormal increases of pumped water.

The operator just needs to provide the known volume in the well between the pump’s “on” and “off” setpoints. The controller will calculate the pumped volume based on the rate of level change in the well during pumping. It also calculates the inflow rate based on the rate of level change in the well just prior to pump startup.

The ultrasonic controller logs this information for review via the controller’s communications options, or by connecting a USB cable and downloading logs directly to your computer. By comparing these results, you can see if inflow rates are greater due to rainwater entering the system. Repair those damaged pipes, and the cost savings begin!

To learn more about how ultrasonic controllers can enable smarter, more efficiently pumping in your water treatment process, Herman Coello is the level product marketing manager for Siemens Industry, Inc. His experience with level instrumentation spans over 25 years, including work with capacitance, radar and ultrasonic level technology. He can be reached at herman.coello@siemens.com