Since the Covid pandemic we have seen significant sales growth around the world, with turnover increasing more than 60% in 2022 compared to the previous year. In terms of volume, component orders remain our core business; however, the number of full systems we are commissioned to produce is increasing every year and now accounts for the majority of turnover.

Most of the demand for complete systems comes from the food and drink industry, but we are also seeing a strong interest in systems for wastewater treatment, as well as specialist applications such as anaerobic digestion and zero liquid discharge.

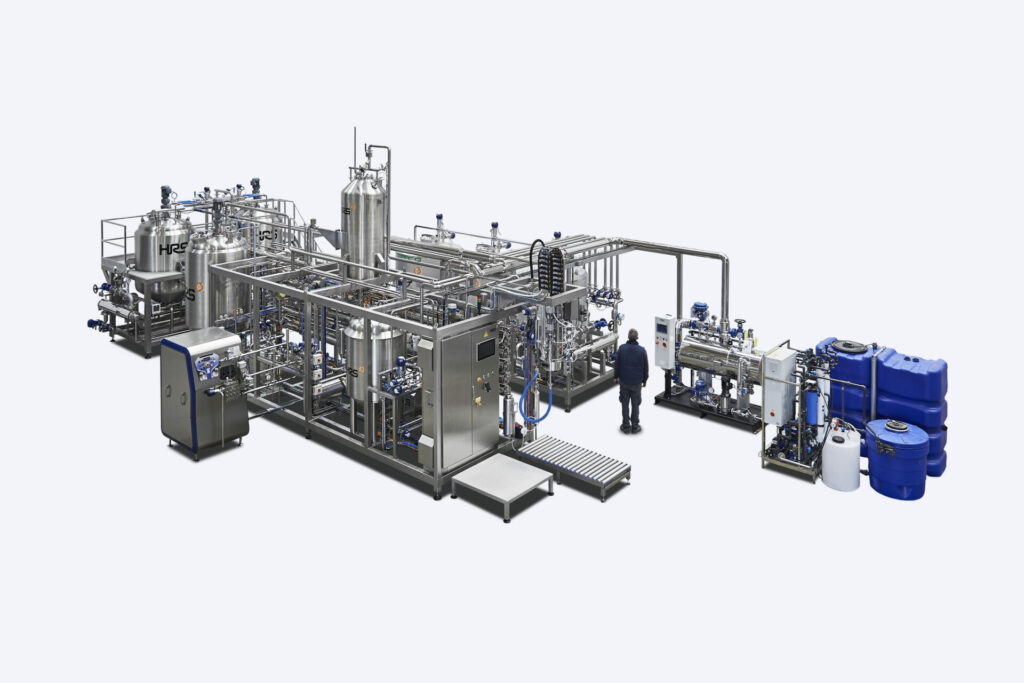

Bespoke system design

Unlike other heat exchanger manufacturers who only sell standard heat exchanger designs, each HRS product is designed to the client’s individual needs. While this can increase the development and production period, it also means that our customers get the right system first time around.

HRS Engineering Manager Alejandro Lopez explains: “The average length of a typical system project from order to commissioning is between 20 and 26 weeks. We design and build each system to the client’s exact specification and we also see each system through the commissioning phase. This can mean travelling anywhere in the world from our manufacturing base in Spain, although we are increasingly seeing clients opt for remote commissioning, which we are happy to facilitate.

“Our most popular systems are for pasteurising juices, similar to those in the fruit growing area near our manufacturing base in Murcia, Spain. Energy recovery, which can reduce energy consumption by 70-80% in juice processing, is increasingly popular and we are designing more systems which incorporate this.

“In the last few years, we’ve completed a number of other systems. For example, those which contain tanks, aseptic filling stations, clean-in-place systems, preparation areas and more. We are actively looking to grow our systems department and have recruited additional engineering staff to accommodate this.”

Types of systems

Thanks to more than 40 years’ experience in the food sector, HRS can offer clients a range of modular or turnkey system solutions, such as our Asepticblock pasteurisers and sterilisers which combine heat treatment, aseptic filling and clean-in-place capabilities in a single system, and which can be skid-mounted for easy installation. Other systems for the food and drink sector include deaeration systems, our I Series of ice crushers and melters, direct steam injection sterilisers (DSI Series) and dedicated CIP and SIP systems. We also provide trial systems for conducting product and processing trials before committing to a final production solution.

For the energy and environmental sectors, we produce a number of concentration and evaporation systems (as well as solutions for Zero Liquid Discharge), and specific systems for anaerobic digestion and wastewater treatment including Digestate Concentration Systems (DCS), Digestate Pasteurisation Systems (DPS) and Biogas Dehumidification Systems (BDS).

Although systems represent an increasing share of our business, component heat exchangers and other products (such as our BP Series of hydraulic piston pumps) underpin our whole business, as well as providing the foundation for many of our complete solutions. We continue to invest in product development and innovation.

Food system case study

HRS supplied a complete sterilisation and aseptic filling solution for a leading specialist in fruit product processing and logistics located in Murcia, Spain. With the capacity to process up to 300,000 litres of fruit juice per day, the main products include concentrated juices such as lemon, orange and mandarin, grape and peach, and some mixed fruit juices.

The first part of the system sterilises the product in an HRS Thermblock steriliser featuring a multi-tube heat exchanger. The product is pre-heated in a buffer tank to 48 °C, then passes through a deaerator to mitigate oxidisation which would spoil the product. It is then heated to pasteurisation temperature (around 92 °C) for one minute to kill any bacteria, before being cooled to 31 °C to preserve quality.

The sterilised product is then placed into sterilised bags within drums using an HRS Aseptic filler. The two-headed design ensures continuous operation, with the product placed into 200 litre bags inside a drum at a rate of 12,000 litres/hr (60 drums/hr). Once full, the drums are then then transported to final customers across Europe and the United States.

The client’s Plant Manager comments: “The HRS aseptic plant was designed and optimised to exactly meet our needs and we are very satisfied with it. It’s simple to use and manage, does exactly what it was designed to do and is extremely reliable. We have had no problems with it since it was installed. The engineering involved is excellent and I would definitely recommend both the system and HRS as a company.”