With decades of experience in the petrochemical sector, DEBEM offers state-of-the-art pumping solutions that support customers throughout the entire project lifecycle—from design and installation to operation and maintenance.

Understanding the Application Context

To appreciate the operational requirements of AODD pumps in the oil and gas industry, it is important to distinguish between the various applications within the sector. The petrochemical field encompasses all stages of petroleum processing, including exploration, extraction, refining, and transportation of products such as fuel oil, gasoline, and derivatives.

- Onshore Applications: In these scenarios, drilling and extraction systems are deployed on land. The drilling rigs are moved across short distances to access adjacent wells with varying profiles, requiring adaptable and mobile pumping equipment.

- Offshore Applications: In offshore environments, operations are conducted beneath the seabed using advanced drilling tools, including thin steel pipes and modular systems. These conditions demand highly reliable pumps that function in remote, high-risk areas.

Given the presence of flammable chemicals, volatile compounds, and high-pressure systems, safety remains a paramount concern in both environments. Moreover, the often isolated and hard-to-access nature of installations increases the complexity of transport and equipment setup.

Advantages of AODD Pumps in Petrochemical Operations

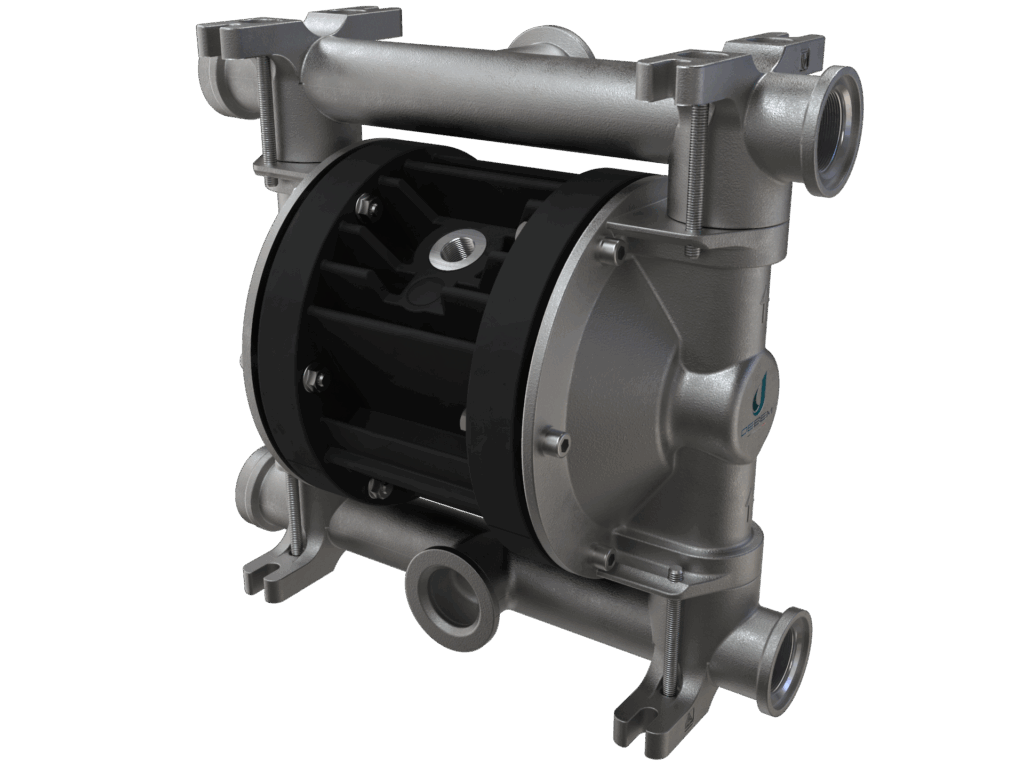

DEBEM’s double diaphragm pumps offer significant benefits in petrochemical applications, enhancing both plant efficiency and safety. Their construction and performance characteristics align seamlessly with the sector’s stringent safety and operational protocols.

Key Benefits:

- Handling of Complex Fluids – AODD pumps are ideal for transferring high-viscosity, abrasive, and corrosive fluids—including volatile hydrocarbons and liquids containing suspended solids. Their construction materials are selected for chemical compatibility and mechanical durability.

- Air-Driven Operation – Operated solely by compressed air, DEBEM pumps eliminate the need for electricity or fuel, reducing explosion risks and ensuring safe use in hazardous zones.

- Hermetically Sealed Chambers – The pump’s diaphragm design ensures a completely sealed fluid chamber, preventing leaks and ensuring safe handling of dangerous substances.

- Ease of Installation and Mobility – Compact and lightweight, these pumps simplify installation and relocation, even in remote or confined areas, and do not require costly infrastructure modifications.

- Certified for Explosive Environments – All DEBEM diaphragm pumps for petrochemical use are ATEX and IECEx certified, making them fully compliant for deployment in environments with high explosion risks.

Typical Applications in the Oil & Gas Sector

DEBEM AODD pumps are used in a wide range of oil and gas operations, including:

- Transfer of fuels and hydrocarbons

- Glycol recirculation and transfer

- Refining process fluids

- Coolant handling

- Condensate and hydrocarbon residue disposal

- Injection of corrosion inhibitors

- Drum and tank unloading

- Drilling mud and slurry evacuation

- Produced water treatment

Each of these processes demands reliable, easy-to-maintain, and intrinsically safe pumping systems, all of which are attributes of DEBEM’s diaphragm pump technology.

Conclusion

DEBEM’s air-operated double diaphragm pumps are specifically designed to address the complex needs of the oil and petrochemical industries. They combine maximum safety, operational flexibility, and low maintenance costs, ensuring continuous performance even in the most challenging environments.

With certifications such as ATEX and IECEx, and a reputation for engineering excellence, DEBEM is a trusted partner for major international operators in the sector. For further information or tailored recommendations, we invite you to contact our sales and technical teams, who will guide you in selecting the optimal solution for your application.