Building on more than 30 years of experience in infrared fusion technology, GF developed the IR-225 M to further improve welding performance for industrial Flow Solutions. The German Design Award jury highlighted how the versatile machine’s design translates technical excellence into practical benefits for operators and installers, meeting a wide range of application requirements including cleanroom conditions.

Designed for efficiency on site

The IR-225 M combines a compact and robust base frame with a clear, operator-focused layout. Intuitive interfaces with multilingual instructions, optimized accessibility, and a stable mechanical design support safe handling and repeatable results.

Thanks to design improvements based on intensive research and in-depth material knowledge, the IR-225 M enables shorter cooling times while extending the range of weldable materials within the same unique, application-oriented dimension range. This increases productivity on site and reduces overall installation time.

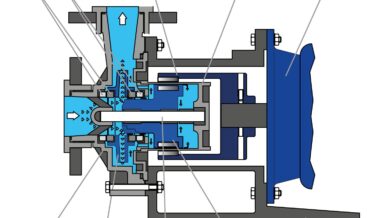

Proven infrared fusion technology for industrial applications

GF’s infrared fusion machines deliver contact-free, high-quality welding of materials such as PVDF, ECTFE, PP-H, PP-n, PE100, and PVC-U. This technology is especially valuable in industries including chemical processing, microelectronics, data centers, and water treatment, where long-lasting, reliable operation is essential.

The machine-controlled fusion process minimizes the risk of welding errors, minimizes preparation effort, and ensures consistent weld quality. Since introducing contact-free infrared fusion technology in 1992, GF has continuously advanced the process, combining technological innovation with practical usability.

Dominik Scherer, Head of Jointing Solutions and GSS & Solution Training at GF, comments:

“Good design is essential when it directly improves daily work on site. With the IR-225 M, design and performance go hand in hand – enabling faster processes, intuitive operation, and reliable welding results for industrial piping systems.”

Immersive visitor experience through a circular booth concept

In addition to the product award, GF also received a German Design Award for its trade fair booth at ISH 2025, built together with M+W Gruppe, Brands and Emotions GmbH, and architect Axel Loritz from imageneering GmbH. This recognition reflects the company’s commitment to customer-centricity in all aspects of its work and its mission to create energy-efficient, affordable buildings with clean and safe drinking water, as well as comfortable spaces. Built with sustainability in mind, the booth concept ensured that displays and materials can be reused repeatedly. Meanwhile, the Digital Twin – the virtual ISH presentation – offers a virtual stand experience and sales training extending the fair. The jury’s statement: “…This strong interplay of architectural clarity and resource-conscious execution impresses at the highest level and sets new standards for sustainable design in temporary spaces.”

Find out more about the IR-225 M infrared fusion machine here.

Find out more about GF’s Flow Solutions for Buildings here.