Elmac Technologies are the leading experts in providing flame arresters that not only exceed industry standards but protect people, property and the planet from the threats posed by flame propagation – especially those created from external ignition sources.

When road or rail tankers are used to collect, deposit or distribute fuels or chemicals, it’s important that any flammable vapours are considered as a key risk. When loading or unloading, it’s critical that a vapour line is first connected to extract the vapours that are likely to have built up in transit, while a grounding wire helps remove the potential static charge before the actual fuel line is connected.

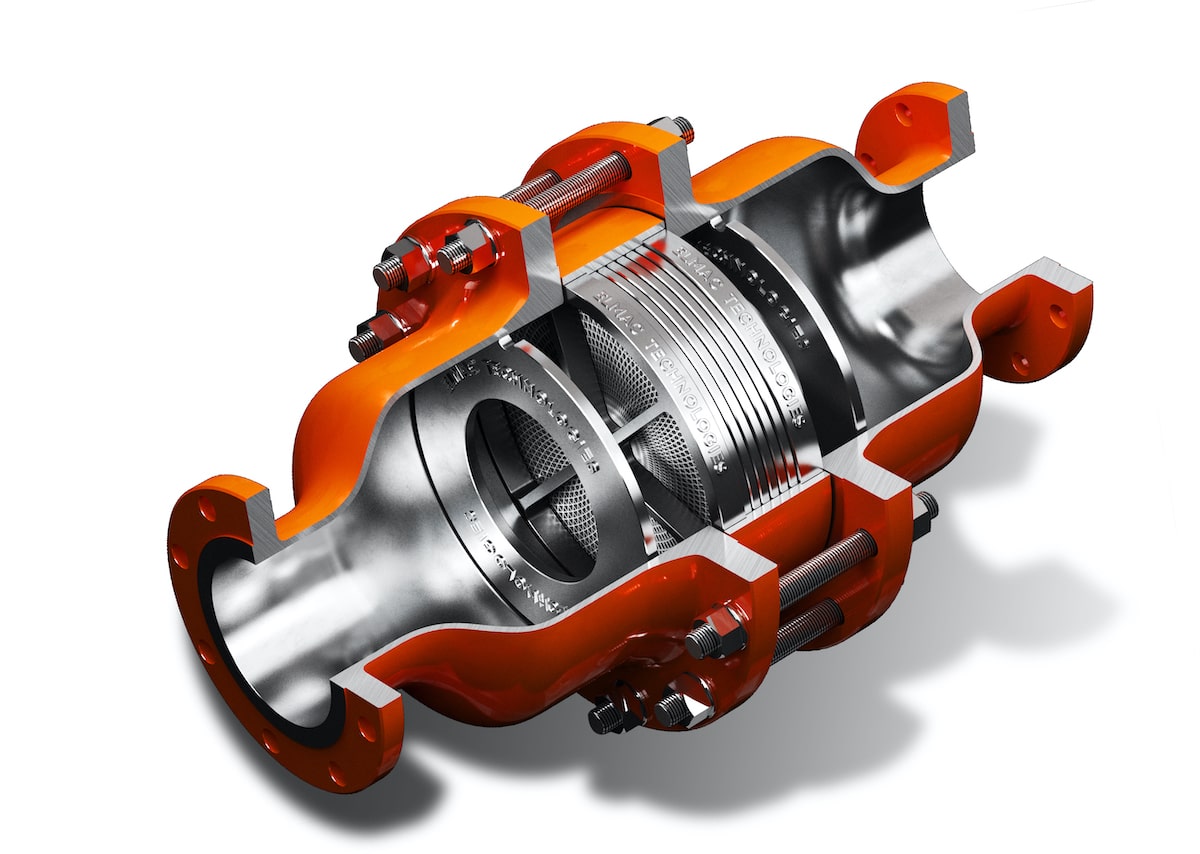

Flame propagation incidents can literally happen in a flash and have the potential to inflict large scale damage to equipment, property, people and the environment. To help protect against such incidents, Elmac’s in-line detonation flame arresters can protect against worst-case explosion scenarios.

The process of mitigating the risk presented by vapours is tried and tested. To prevent against the build-up of vapour pressures or displacement when fuel enters a storage tank, the vapour recovery hose will lead to a recovery unit where the vapour will be safely converted back into fuel with any harmless emissions being released back to the atmosphere.

Placing detonation flame arresters in the hoses and common fuel lines will help protect against dangerous explosions. The type of flame arrester required is legislated by the volatility of the vapour and Elmac’s UCA or UCB in-line detonation flame arresters are typically selected.

The UCA and UCB Series of In-Line Unstable Detonation Flame Arresters are designed to prevent the propagation of flames, from gas or vapour explosions, in pipelines under the most severe unstable detonation scenarios. This type of arrester is specified for use in pipeline systems where the distance between the source of ignition and arrester is significant and/or where detonations are possible.

Elmac’s UCA Series of Unstable Detonation Flame Arresters are ATEX certified for gases in Explosion Groups IIA1 and IIA, while the Elmac UCB Series Unstable Detonation Flame Arresters are ATEX certified for gases in Explosion Groups IIB1, IIB2 & IIB3. All of Elmac’s flame arresters are manufactured in accordance with EN ISO 16852 and approved to ATEX Directive 2014/34/EU.

Lew Bingham, Managing Director, Elmac Technologies says: “Even something as simple as accidentally uncoupling the grounding wire before the vapour line can allow a static electrical spark to ignite the residual fumes in the hose. It’s therefore easy to see why explosion protection devices are a pre-requisite when working in the hazardous environments of vapour recovery and other operations associated with fuel distribution and storage.

Operational requirements demand absolute reliability, minimal maintenance and, of course, the need to be cost effective. That’s why Elmac’s products are routinely specified in vapour recovery systems”.