With the accelerating adoption of EVs (Electric Vehicles) we are already getting used to charging batteries in our cars instead of filling a fuel tank. Major manufacturers in the transport sector, construction equipment and earth-moving machinery are also focusing their innovation budgets on electrification.

There is a similar trend in the world of mobile pump units, we see a greater focus on the environment, energy use and emissions. In the anticipation of these future trends, BBA Pumps innovation team has delivered a huge achievement. In addition to the existing electric mobile pumps on mains power, we are now introducing the first battery electric pumps.

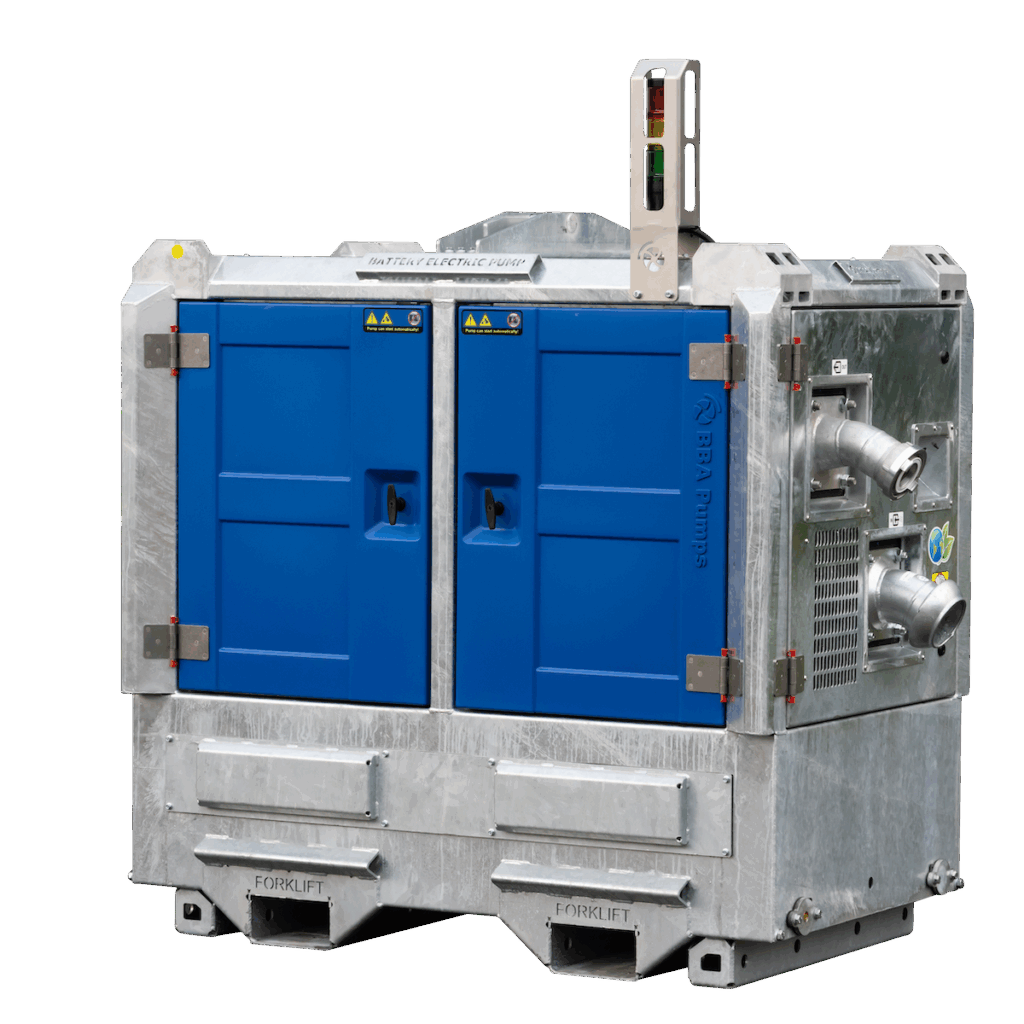

Battery electric pumps

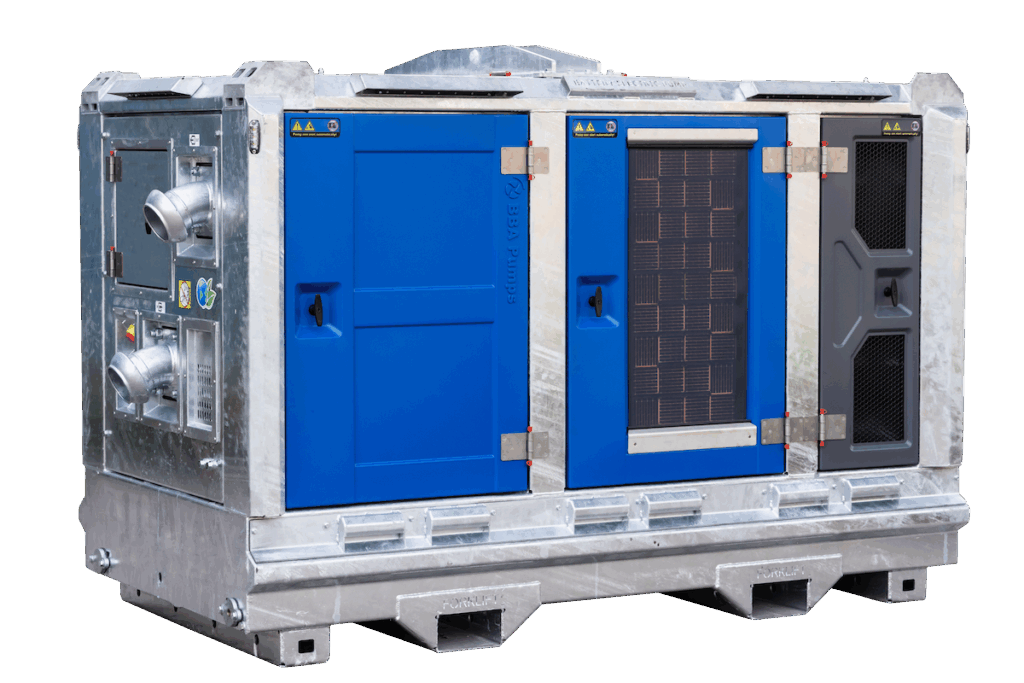

The BBA Pumps battery electric mobile pumps are driven by an electric motor and are assembled inside a canopy. Unlike before, the role of the canopy was to reduce the noise, battery electric pumps are super quiet in themselves. The canopy is now part of the overall design, housing all electrical components and a Lithium Iron Phosphate (LiFePO4) battery pack.

As standard the pump unit is equipped with energy-saving features. By using the automatic level control, energy consumption can be reduced. With smart management, the running time on the battery pack can be significantly increased.

A solar panel in the door of the canopy ensures that the 12-volt traction battery remains charged. This separate battery is required to activate the systems at start-up and the solar panel also contributes to reducing total energy use.

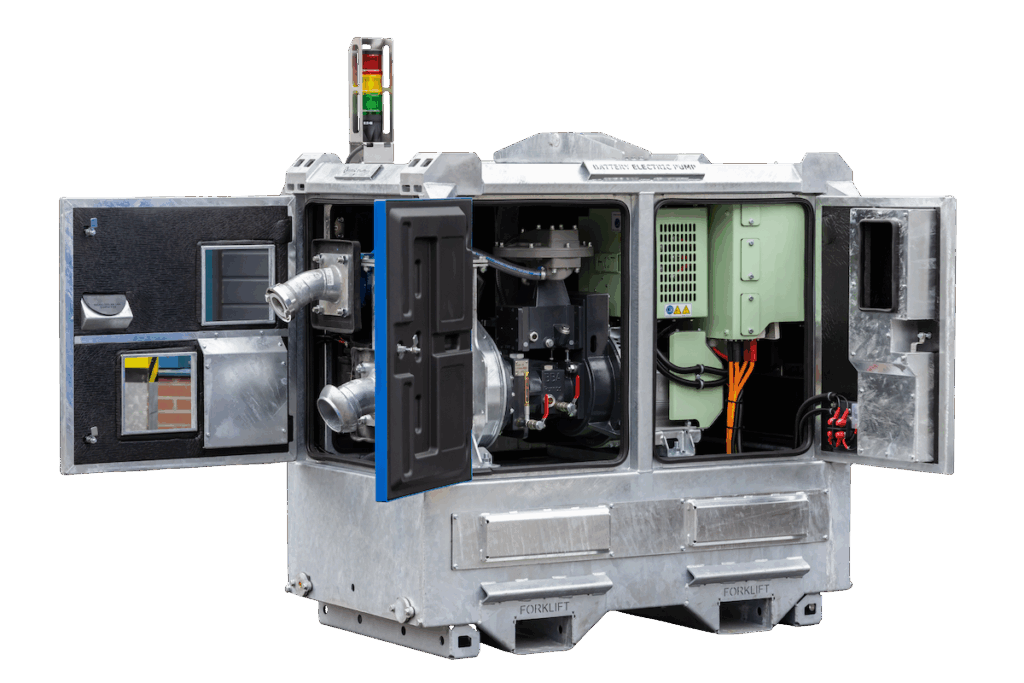

Battery electric + DPU dewatering pump

With battery electric + DPU, the pump is driven by an energy-efficient electric motor. A built-in frequency controller controls the motor. The pumpset is equipped with a grid connection and a battery pack. When the unit is connected to grid power, the energy flows automatically through the battery and is used for driving and charging.

In the absence of grid power, the electric motor runs on energy drawn from the battery pack. When the battery is emptied, a small built-in generator automatically switches on to recharge the battery. The generator is a 1-cylinder diesel power unit (DPU) with DriveOn® technology. The pumpset is equipped with its own fuel tank for this purpose. The diesel generator always runs at an efficient load, resulting in minimal emissions.

Features of the BBA electrical pumps

- The energy consumption (joules) of electric pumps is much lower than that of the same pump powered by a diesel engine. This is due to the high efficiency of the current generation of electric motors, we see efficiencies of up to 96%.

- Pump drives often run at part load because users prefer to select the operating point at Best Efficiency Point. A major advantage of electric motors is that the efficiency remains approximately the same at lower power consumption. At ¾ load, the efficiency is sometimes even slightly higher than at full load.

- By using a frequency controller on an electric pump with automatic level control, further reductions in energy usage can be achieved. The pump system automatically starts and stops as the liquid level rises or falls, in doing so the pump uses energy only when necessary.

- The noise level of electrical machines is extremely low. We also observe this with the BBA Pumps electric mobile pumps. The official ISO 3744:2010 noise reports are sometimes even annotated; “There was interference noise from chirping birds”. Our quietest pump set has an incredibly low noise level of 30 dB(A) at a distance of 10 meters.

- The Life Cycle Cost (LCC) distribution of electric mobile pumps is very different from diesel-driven pump sets. You can imagine, the costs of regular maintenance of a diesel engine will increase significantly during the course of its working life. An electric motor requires little or no maintenance. But the biggest LCC difference will be reflected in the energy costs. Fuel prices are currently high and continue to rise each year. Electricity prices are low and during sunny days, or when there is a lot of wind, we have a surplus of sustainable energy and prices are therefore significantly reduced.

- From the beginning of 2025, BBA electric mobile pumps will be fitted with a Human Machine Interface (HMI) touchscreen control as standard. This provides optimal user-friendliness and offers sufficient opportunities to expand functionality with new (energy-saving) features being added in the future.