To calculate the ROI, you will need to gather the upfront cost of purchasing an analyzer and the ongoing cost of ownership to understand your anticipated expenses. Then, note the expected benefits and resulting savings the analyzer enables – including improved production outputs and reduced downtime.

Every analyzer measurement aims to ensure that the desired amount of on-spec product is being produced safely and at the lowest cost. Multiple analyzers, operating either manually or automatically, will help your plant achieve this goal across three key categories: safety and environment, process control, and quality assurance. Each category has its own unique implication on your ROI analysis.

Safety and Environment

Safety is the highest priority for fluid processing plants. Process analyzer technology measures conditions that might endanger equipment and the people nearby. Fast analytical data may be one of the only ways to avoid a potential violent chemical reaction that could rupture a pipe or vessel and endanger personnel. This aspect alone may justify the expense of a quality process analyzer – or even several analyzers.

Additionally, you must adhere to compliance requirements. For example, continuous emissions monitoring systems (CEMS) and effluent water analyses are legally required in most locations. Therefore, your plant must install safety and environmental monitors regardless of their cost and ROI.

Process Control

Process analyzers help plants remain profitable by enabling the fine-tuning of process streams to ensure high-quality products. Current market conditions often dictate a plant’s process control philosophy. When demand is soft, and the plant is running at below maximum capacity, process control focuses on minimizing production costs while maintaining the desired quality. When demand is high, and the plant can sell as much as it produces at a good price, throughput is far more important.

A product that exactly complies with customer specifications is the expectation. The cost of creating poor product is enormous, so plants always need to make product that’s at or better than specified to ensure sales.

Control systems aim to reduce “giveaway” – the cost of producing too high of quality – by reducing random product quality variations. Figure 1 illustrates the concept. When product quality variations are large (blue curve), the plant produces a higher average quality, for fear of making an off-spec product. Achieving this additional quality will either increase the cost of production, reduce throughput, or both. Analytical measurement and control help to reduce the quality variation (green curve), so operators can drive the average quality down closer to the specification limit, thus making their product more efficiently or more copiously.

The ROI of a process analyzer used for control is calculable from the value of increased throughput in a seller’s market or the reduction in operating costs in any market.

Quality Assurance

The accuracy of process analyzer measurements can be vital to a producer’s bottom line. A wrong analysis could be catastrophic if a bad product is sent to a customer or a good product is rejected simply because an analyzer is out of calibration. A process analyzer that helps to mitigate either scenario can easily justify its expense and continued cost of ownership.

Understanding the Costs

Before deciding on an analyzer purchase, count every associated expense. This includes the upfront cost of acquisition, installation, and startup as a capital investment. Your ROI is then the net cash stream over the lifetime of the equipment.

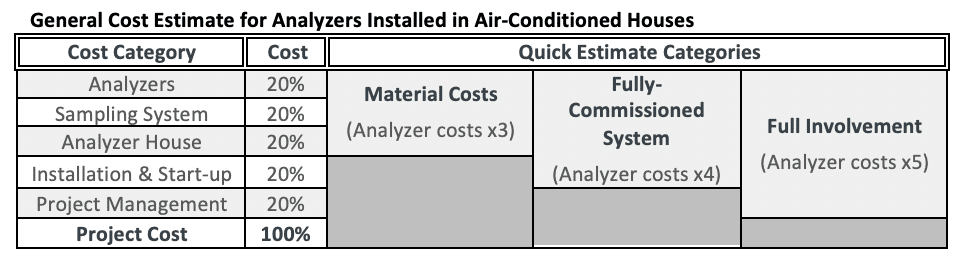

The table below provides a general estimate of the costs associated with various kinds of analyzers installed in air-conditioned analyzer houses. The cost categories average about 20% each:

If you need to present a case for purchasing a new analyzer, you can calculate the ROI using a simple spreadsheet function. Many plants will anticipate a 50% ROI or higher. Make sure your findings are defendable and that you truly understand the benefits obtained from the analyzer. A dissenting measurement could be a future insurance policy. Its purpose may be to flag an unlikely, but conceivable, plant upset, which could potentially save your plant a fortune.

About the Author

Karim Mahraz is Product Manager, Analytical Instrumentation for Swagelok. He can be reached at karim.mahraz@swagelok.com.

An original version of this article appeared on the Swagelok Reference Point blog here: www.swagelok.com/en/blog/calculating-roi-process-analyzer-technology.