Most companies have one or more digitalization initiatives underway as demonstrated in this survey conducted at the 2019 Emerson Exchange during the Chemical Industry Forum session.

Companies are already spending money on digitalization projects, but not necessarily with a good roadmap for where they are going. Surveys show that people challenges and not fully understanding the business impact of the technology are the biggest roadblocks to digital transformation project success.

Emerson through its industry consulting practice has recently engaged with a number of key manufacturers and producers to help them identify and prioritize a digitalization roadmap based on which opportunities will have the most impact on the Key Performance Indicators (KPIs) for the site. These KPIs are the metrics they use to measure their own operational performance, and also as a comparison against their peers through independent benchmarking in quartile performance.

It is nearly impossible to be top quartile in all benchmarked metrics, but we know that sites will drive improvement in a subset of the metrics and improving a quartile can have significant financial return as shown below. For example, going from average to top quartile in safety would mean 3 times fewer recordable incidents. In reliability, the top quartile has 4% higher availability at half the maintenance costs than an average performer.

Top quartile producers spend 20% less on operating costs and have 10% high utilization rates than average performers. And environmentally focused manufacturers in the 1st quartile spend 30% less on energy and have 30% less emissions than the average.

Our methodology involves executive interviews, historical site benchmarking, and experiences gained working with refiners and petrochemical producers to identify opportunity for improvements in the site-driven KPIs. We then use a facilitated workshop with the key site stakeholders, including management from operations, control systems, I&E, IT, Logistics, Quality, and HSSE to uncover & remove barriers, and build consensus around the best opportunities to use automation technologies to improve the targeted KPIs.

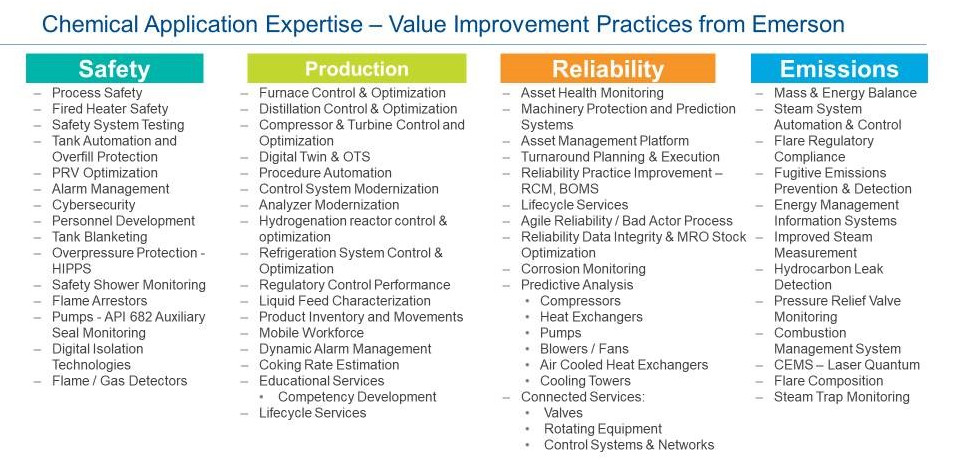

Over the course of many years conducting these workshops and executing projects, a library of proven value improvement practices (VIPs) have been developed. These VIPs are a comprehensive list of proven automation opportunities collected across all the Emerson technologies. These VIPs represent best practices for Automation technologies which have been proven to have an impact on one or more critical KPIs. For example, here are VIPs for an ethylene complex.

At the end of the workshop, the objective is to come up with a short list of digital transformation initiatives with an estimate of the potential benefits as well as actions, resource assignments and target dates to advance the initiative. The Emerson industry consultants have conducted more than 50 of these workshops with refiners and chemical producers over many years helping to deliver proven business improvements. In the next series of blog posts, we will cover some of the key VIPs for ethylene complexes to improve production, reliability, safety, energy and emissions.

From Jim: Visit the Downstream Hydrocarbons section on Emerson.com for more on the technologies, methodologies and solutions to help you drive business performance improvements.

Marcelo Carugo

Pete Sharpe