For many of Airtecs clients, ensuring accurate compressed air consumption monitoring isn’t just about keeping operations costs under control. They need constant, rigorous air consumption control to avoid wasting valuable energy resources. In the case of one of Airtecs clients, a food processing plant, the need for better compressed air management was apparent, and with SUTO, we were able to provide the right solution.

The Situation

In 2021, this food processing facility hired a new plant manager, who discovered that the compressed air system he inherited was a complete mess. They had numerous points of mismatched air supply and demand, not to mention leaks. In addition to a poorly-optimized system, they needed to be sure that they minimized compressed air consumption. The facility manufactures frozen foods, where most packaging machines require high consumptions of compressed air. Naturally, he brought Airtec on to help him get his compressed air system under better control. Since then, Airtec have helped implement efficiency and energy saving solutions using SUTO’s monitoring products.

Approach

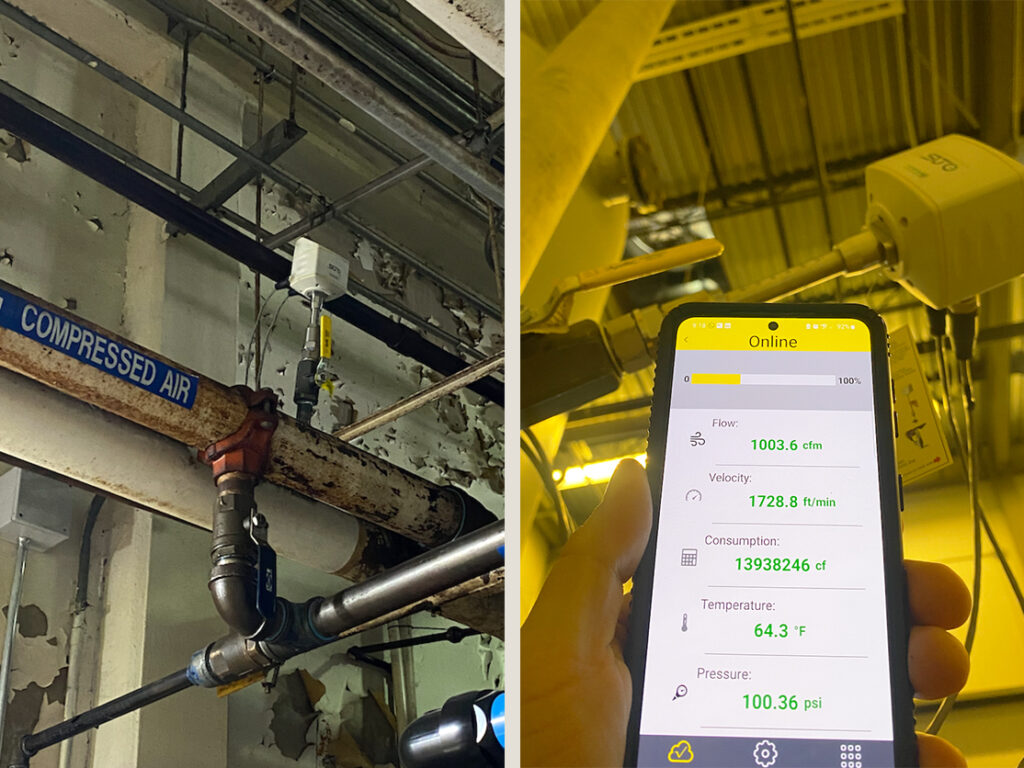

Airtec helped this facility overcome the lack of knowledge on where their air was being wasted, so Airtec introduced them to SUTO’s S430 Compressed Air Flow and Consumption Meters. Working with facility staff, Airtec was able to determine that the best way to know how much air the plant is consuming, is by measuring it. This would help them to better understand how much air the plant consumes on a daily basis. Until this point, they had no idea how much air they were using or how much room for improvement and optimization there could be.

SUTO S4C-FS App to easily monitor real-time data

After installing the S430 meters, Airtec integrated them with the SUTO S4C-FS Software. Almost immediately, the access to real-time data exposed numerous areas that could be improved. With this data in hand, they were able to use regularly-scheduled breaks in production to find the leaks that were causing their system to continually generate air.

Long-Term Results

(insertion type)

With just a handful of SUTO products, this facility gained a significant boost to their energy efficiency. More importantly, this facility was able to begin their transition away from wasteful analog methods to efficient, datapowered monitoring and maintenance. SUTO’s products gave them the tools they needed to use real-time monitoring to better understand their system, and to plan to implement similar solutions at multiple levels in the future.

Product In Use: S430 Flow Meter for wet compressed air (insertion type)

The S430 compressed air flow meter is made for the use in wet air, therefore it can be used directly at the compressor outlet. At this point other flow meters are likely to fail, becuase they are not able to withstand the wet and hot air. The S430 can be used in excatly these conditions, making it the perfect tool for compressed air audits and compressor efficiency measurements.