The XY-TEK CG series ultrasonic flow sensors/flow meters provide the biopharmaceutical industry with a non-invasive solution for verifying the performance of fluid pumps in the bioprocessing systems, monitoring pipeline integrity, and facilitating automated, intelligent bioproduction management.

CG series clamp-on ultrasonic flow sensors do not directly contact the fluid being measured, allowing for repeated use without costly disinfection or gamma irradiation. The non-invasive design makes them especially suitable for high-sanitization environments, such as single-use biopharmaceutical systems.

Featuring a compact design, the CG series ultrasonic flow sensors can be easily clamped onto flexible plastic tubing. They enable accurate and reliable measurement of bioliquid without interrupting the existing setup.

Industry Challenges

Contamination

Maintaining hygiene and sterility is critical in biopharmaceutical production Any contaminants introduced during measurement can compromise product quality. Therefore, measurement devices must be non-invasive and easy to clean or sterilize to avoid direct contact with the measured liquids.

Flow Rates

Flow rates can vary significantly due to changes in production cycles, batch sizes, or formulation adjustments. Accurately measuring these variable flow rates requires measurement technologies that can adapt and provide reliable data regardless of fluctuations, ensuring consistent product quality.

Air Bubbles

Air bubbles and particulate matter in the biofluid can interrupt flow and affect measurement accuracy. This is particularly relevant in biopharmaceutical processes where precise dosing and mixing are critical.

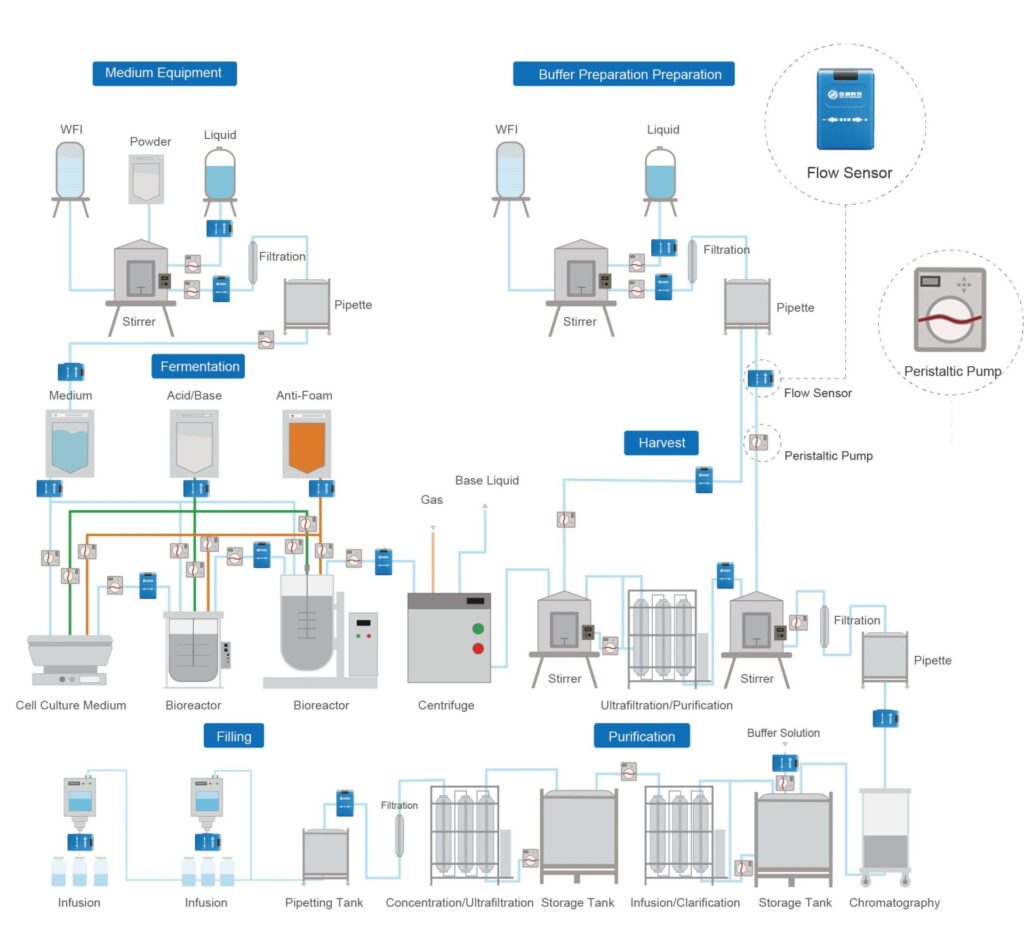

Application Overview

XY-TEK cG series ultrasonic flow sensors/flow meters can be used in the following bioprocess:

- Medium Preparation – Buffer Preparation: Replace volume measurement device.

- Bioreactor (Continuous / Perfusion) – Manage the inflow and outlow of fluids.

- Filtration – Control the process conditions during the filtration process.

- Filling Equipment – Measure the volume of fluid filled into the container.

- Cell Inoculation – Controls the injection of cell lines into the reactor

- Centrifuge – Verifies that fluids are flowing

- Chromatography – Balance the amount of acid/base delivered to the system.

By leveraging non-invasive ultrasonic flow sensors, biopharmaceutical manufacturers can achieve high levels of accuracy, reliability, and efficiency in flow measurement processes, ensuring industry stringent compliance and maintaining product quality.

Application Highlights

Hygienic and Sterile Design

The CG series clamp-on ultrasonic flow sensors feature a non-invasive design that ensures no direct contact with the measured liquid, maintaining the highest standards of hygiene and sterility.

Compact and Efficient

With a compact size that integrated circuits and advanced computing systems, CG series are designed for flexible installation, making them ideal for liquid flow measurement in biopharmaceutical equipment.

Minimal Pressure Loss

The clamp-on design eliminates clogging, steering, and dead space, resulting in minimal fluid pressure loss.

Versatile Output Options

The CG series offers multiple output methods, including analog, frequency, switching and RS485, llowing for seamless integration with existing customer systems. Switching output can be easily configured for flow switch, bubble detection, dosing, and flow rate output.

Effortless Installation

Designed for convenience, the CG series ultrasonic flow sensors can be easily clamped onto the outside of the tubing without disconnecting any lines. This approach eliminates system downtime and significantly enhances installation and dismantling efficiency.

High Accuracy

Supporting bi-directional measurements. Flow range: 10mL/min~100L/min. Measurement accuracy up to ±1%.