Therefore, accurately measuring the changes in fluid flow rate within the device tubing is a key issue that manufacturers need to focus on.

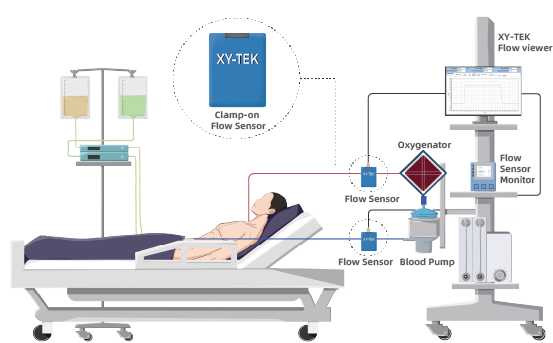

The XY-TEK CG series ultrasonic flow sensors/flow meters provide medical device manufacturers with a non-invasive solution for verifying/monitoring the performance of fluid pumps of the devices.

The non-invasive design makes CG series particularly suitable for medical devices with high accuracy flow measurement demand, such as ECMO, hemodialysis machines, cardiopulmonary bypass machines, surgical perfusion systems, organ transplantation systems, heart-lung machines, blood pumps, etc.

Industry Challenges

Dynamic Flow Conditions

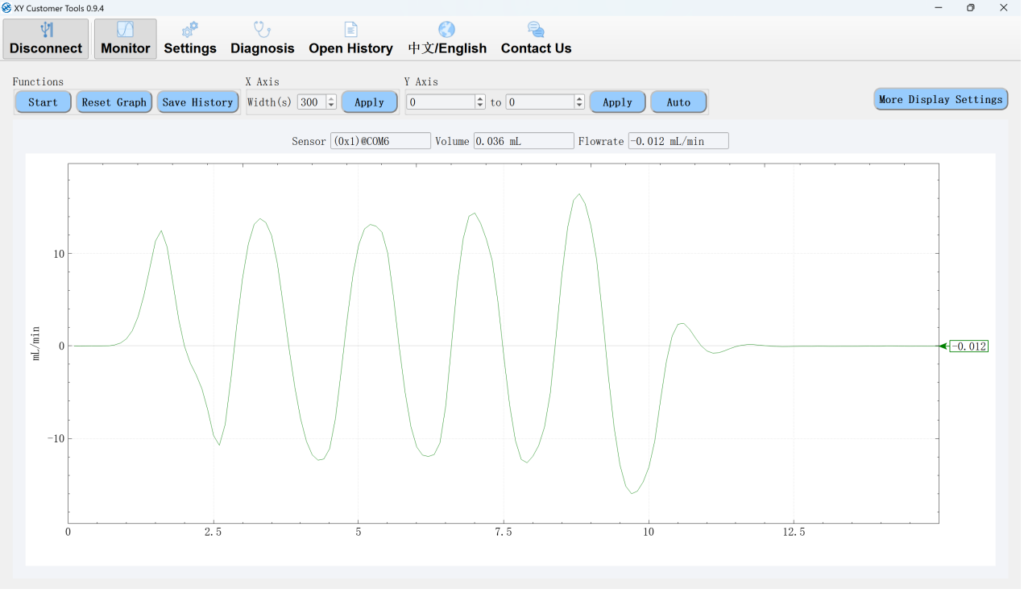

In devices such as artificial heart pump, ECMO and hemodialysis machines, flow rates can fluctuate rapidly and unpredictably due to patient conditions and treatment processes. Accurately measuring these dynamic flow conditions in real time poses a significant challenge.

Cleanliness

For devices that handle blood, such as hemodialysis machines and ECMO systems, it is essential that measurement devices do not come into direct contact with the blood or dialysis fluid. Non-invasive measurement techniques are designed to prevent contamination while being easy to maintain and inspect.

Bubble Detection

Air bubbles in the fluid circuit can lead to inaccurate measurements and create potentially dangerous situations for patients. A reliable method to measure liquids while simultaneously identifying and alerting operators to any air bubbles is a considerable challenge.

Application Overview

XY-TEK CG series ultrasonic flow sensors/flow meters can be used in the following medical devices:

ECMO

Measurement of blood flow rates and detection of air bubbles in the circuit to ensure patient safety and optimal function.

Hemodialysis Machines (HD)

Continuous monitoring of blood flow to provide real-time feedback on treatment efficacy and to adjust parameters as needed.

Peritoneal Dialysis (PD)

Ongoing monitoring of blood flow to ensure proper dialysis and timely adjustments to the treatment process.

Organ Perfusion Systems

Measurement of both perfusion fluids and blood flow to ensure adequate nutrient and oxygen delivery to organs during transplantation or therapy.

Heart Pumps

Continuous monitoring of liquid flow within heart pump systems to maintain optimal cardiac support and function.

Contrast Media Pumps

accurate measurement of injection doses of contrast agents to enhance imaging clarity and improve diagnostic accuracy.

Cryoablation Devices

Exact measurement of heating liquids to ensure controlled application of thermal energy for effective ablation procedures.

Application Highlights

Hygienic and Sterile Design

CG series clamp-on ultrasonic flow sensors does not direct contact with the bio fluid, which help maintain the sterility of biopharmaceutical products. It is critical in ensuring that the integrity and safety of the products are preserved, protecting against contamination risks.

Compact and Efficient

With a compact size that integrated circuits and advanced computing systems, CG series are designed for flexible installation, making them ideal for liquid flow measurement in medical devices.

Minimal Pressure Loss

The ultrasonic TOFD flow measurement method has a negligible impact on the bioliquid. The design eliminates clogging, steering, and dead space, resulting in minimal fluid pressure loss.

Versatile Output Options

The CG series offers multiple output methods, including analog, frequency, switching and RS485, allowing for seamless integration with existing customer systems. Switching output can be easily configured for flow switch, bubble detection, dosing, and flow rate output.

Effortless Installation

Designed for convenience, the CG series ultrasonic flow sensors can be easily clamped onto the outside of the tubing without disconnecting any lines. This approach eliminates device downtime and significantly enhances installation and dismantling efficiency.

High Accuracy

Supporting bi-directional measurements. Flow range: 10mL/min~100L/min. Measurement accuracy up to ± 1%.