Gas injection involves drilling a secondary borehole and inserting a gas injection line into the formation. Gases such as natural gas, nitrogen (N₂), or carbon dioxide (CO₂) are pumped into the reservoir to increase pressure, thereby enhancing crude oil extraction. This technique is widely recognised as a crucial pressure maintenance procedure, ensuring continuous and efficient production.

The Challenge of Flow Measurement in Offshore Gas Injection

Precise gas flow measurement is critical during gas injection operations. Operators must closely monitor gas usage to optimise production and maintain safety. However, offshore platforms present significant challenges for many flow measurement technologies.

Extreme operating conditions, including pressures up to 300 bar and harsh environmental factors, can accelerate the wear and tear in internally mounted devices such as differential pressure (DP) meters. On a Norwegian offshore platform, DP meters experienced increased maintenance demands and occasional system downtime due to the need for repairs and replacements.

The Advantage of Clamp-On Ultrasonic Flow Measurement

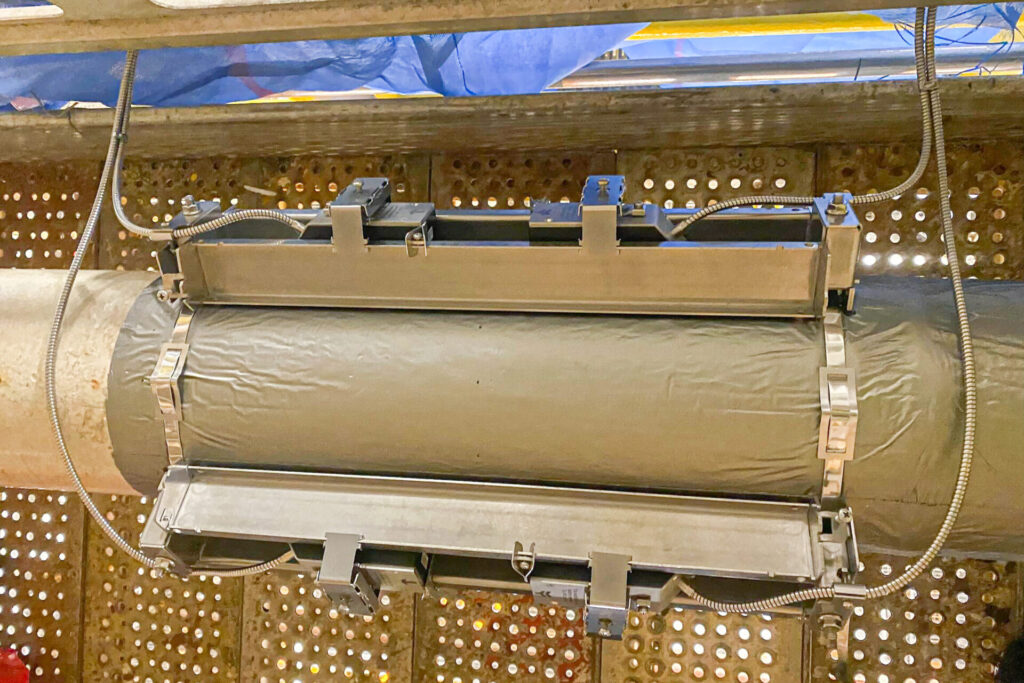

To address these challenges and reduce maintenance requirements, the platform operator explored alternative approaches. Emerson’s Flexim clamp-on ultrasonic flow measurement technology provided a robust and effective solution. This non-intrusive method utilises externally mounted transducers, eliminating exposure to high-pressure conditions and preventing internal wear.

Flexim acoustic technology offers a broad measurement range and accurately captures even the lowest flow rates. Furthermore, installation is seamless and does not require pipeline modifications, allowing continuous operation during setup.

Successful Implementation of Flexim Technology

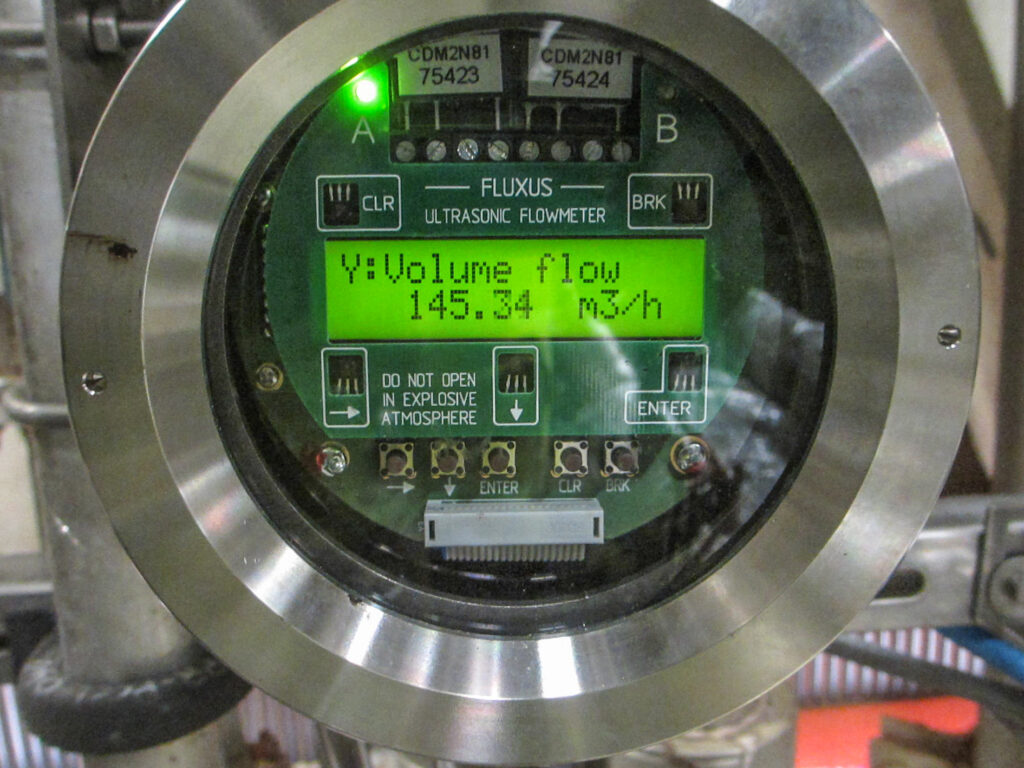

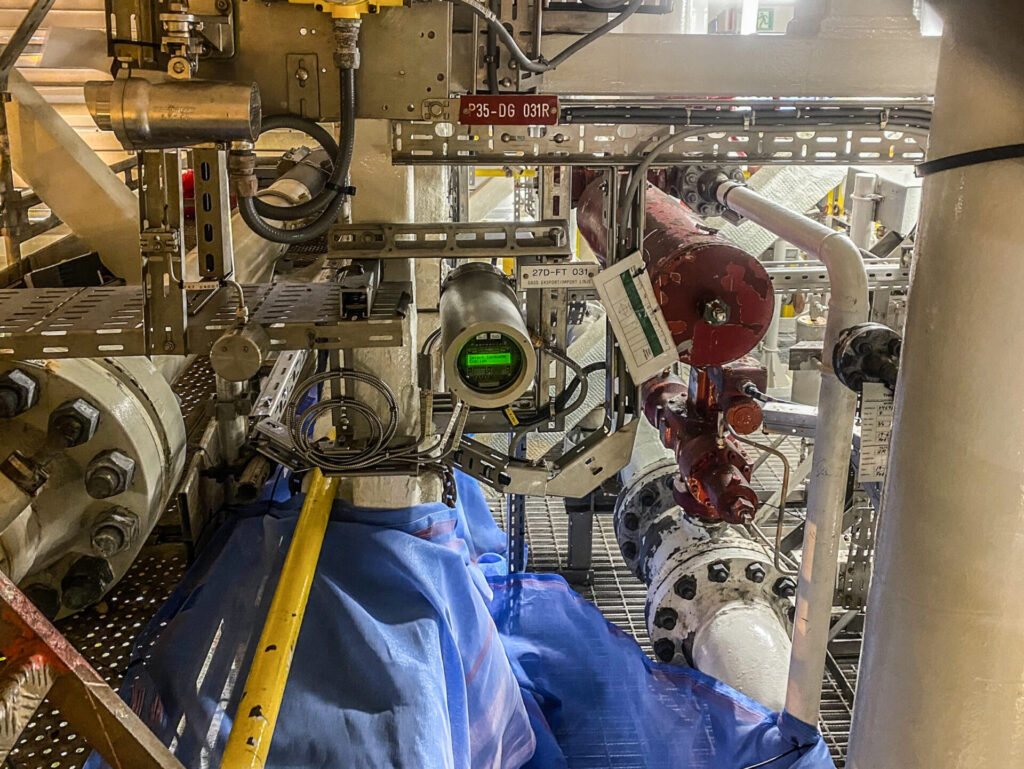

Rigorous testing was conducted on the platform’s gas injection measurement points using a portable ultrasonic flow meter. Diagnostics confirmed the feasibility of a fixed installation, leading to the deployment of a permanent ultrasonic measurement system.

To withstand offshore conditions, the selected devices featured SS316 stainless steel housings, ensuring resilience in saliferous environments. For maximum reliability, each measurement point was equipped with dual-channel sensors. The system operates via a simple 4-20 mA output, integrating seamlessly with the platform’s process control system for real-time data acquisition.

Expanding Non-Intrusive Measurement Applications

Beyond gas injection, Flexim instrumentation is extensively utilised across the offshore platform, providing reliable measurement solutions for various applications, including:

- Fire pump testing and general check metering with ATEX Zone 2 portable meters

- Oil outlet on test separator

- Oil outlet on separator

- Gas import/export lines

- Chemical and water lines

By adopting clamp-on ultrasonic flow measurement technology, offshore operators can achieve unparalleled accuracy, minimise maintenance, and ensure uninterrupted production efficiency. Flexim solutions are redefining flow measurement in the demanding oil & gas industry, setting new standards for reliability and performance in offshore operations.