FCI’s reliable ST75 Flow Meter utilizes advanced thermal dispersion sensing technology, providing accurate and consistent measurements even in challenging environments. This meter is ideal for processes requiring precise dosing or injection of many gases: Ammonia, Argon, Carbon Dioxide, Chlorine, Ethane, Fluorine, Nitrogen, Ozone, Refrigerants, Sulfur Dioxide and many more.

The ST75 Series Thermal Air/Gas Flow Meter is suitable for gases that are commonly used in a wide range of industries. It is widely relied upon for processes that produce advanced materials, biomedicines, chemicals, electronics, food/beverage, mining/metals, oil/gas production and refining, plastics, pharmaceuticals, pulp/paper, water treatment and many more.

All gas dosing and injection processes have one important thing in common: The gas flow rate and the totalized flow of gas must be measured with high accuracy and repeatability for batch quality control and low-cost operational efficiency. The precision ST75 Flow Meter’s solid-state thermal dispersion mass flow sensing element with platinum RTD’s is housed in equal mass thermowells for years of trouble-free service.

This meter measures virtually any gas or gas mixture. It is calibrated to measure specific gases in FCI’s own advanced NIST-qualified Calibration Laboratory. It is available for demanding applications requiring a flow range from 0.04 to 559 SCFM (0.07 to 950 NCMH), depending on line size, which is useful in low-flow applications requiring small doses.

The ST75 Flow Meter, when used in variable demand cycles due to small batch or other continuous process production requirements, is factory preset to 100:1 turndowns. It features highly dependable accuracy to ±1% of reading with ±0.5% repeatability in line sizes from 0.25 to 2 inches (6 to 51 mm). Engineers can depend on it for precise flow control of gases to ensure high-quality end-products from either batch or continuous processes.

This meter’s flow element features a rugged, no-moving parts design for superior reliability. This unique design provides extra confidence where process safety is a big concern with other types of meter technologies, which rely on movable parts that can break over time in high turndown applications. These incidents can send dangerous meter debris crashing through pipes conveying hazardous combustible gases.

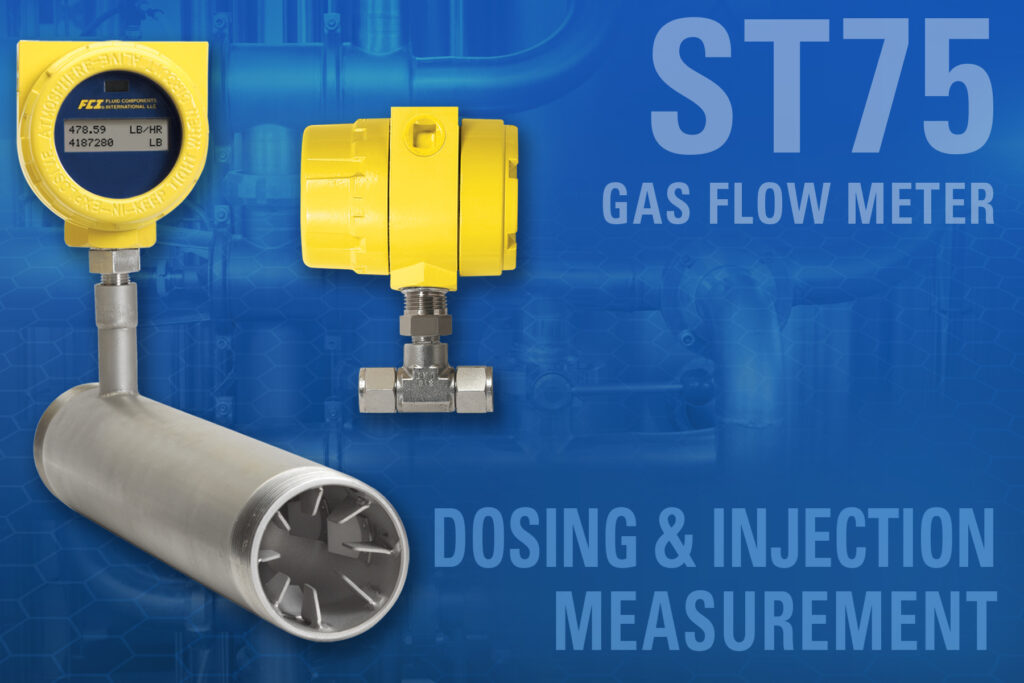

The Model ST75 Flow Meters are designed with a choice of mounting configurations. They feature a full digital display and are also available with optional transmitter remote mounting capabilities for hazardous plant environments. The remote transmitter can be mounted up to 100 feet (30 meters) away from its thermal mass flow sensor in piping or ductwork and connected via two 0.50-inch FNPT or M conduit connections.

For tube service in a 0.25-inch line, the compact ST75 Flow Meter’s round transmitter is 3.28 inches (83 mm) wide and stands only 5.7 inches (144,8 mm) above the centerline of the flow tube. Its relatively small footprint makes it simpler to add measuring points where close control of the process is desirable, such as in gas dosing and gas injection applications.

In crowded equipment layouts that compromise straight pipe runs for accurate flow measurement with other technologies, the Model ST75AV Meter features a built-in Vortab flow conditioner. Nearby pumps and valves that affect the accuracy of other meter technologies are no problem with the ST75 Meter’s built-in Vortab Flow Conditioners, which create a regular, smooth flow profile in the pipe for dependable flow measurement.

This meter’s fully scalable dual 4-20mA standard outputs are user assignable to flow rate and/or temperature and a 0-1kHz pulse output of total flow. Two-way HART bus communications are available with the Models ST75A and ST75AV. The instrument can be ordered for input power with either 18 to 36 Vdc or 85 to 265 Vac.

The ST75 Flow Meter withstands process temperatures from 0 to 250°F (-18 to 121°C). It operates at pressures up to 240 psig [16.5 bar (g)] with a standard t-fitting (NPT female) process connection. With a tube process connection, the meter withstands 600 psig [41 bar (g)].

Its electronics are housed in a rugged, IP67-rated enclosure with dual conduit ports in either NPT or M20 threading. The models ST75A and ST75AV include HART or Modbus as well as NAMUR-compliant 4-20 mA outputs and SIL compliance rating. The complete instrument carries global Ex agency approvals for Division l/Zone 1 installations.

A DwyerOmega brand, FCI delivers precise flow and level instrument measurement solutions using advanced thermal dispersion technologies. With more than 60 years of experience and the world’s largest installed base of thermal flow meters, flow switches, and level switches, FCI is the trusted expert in flow and level instrumentation.