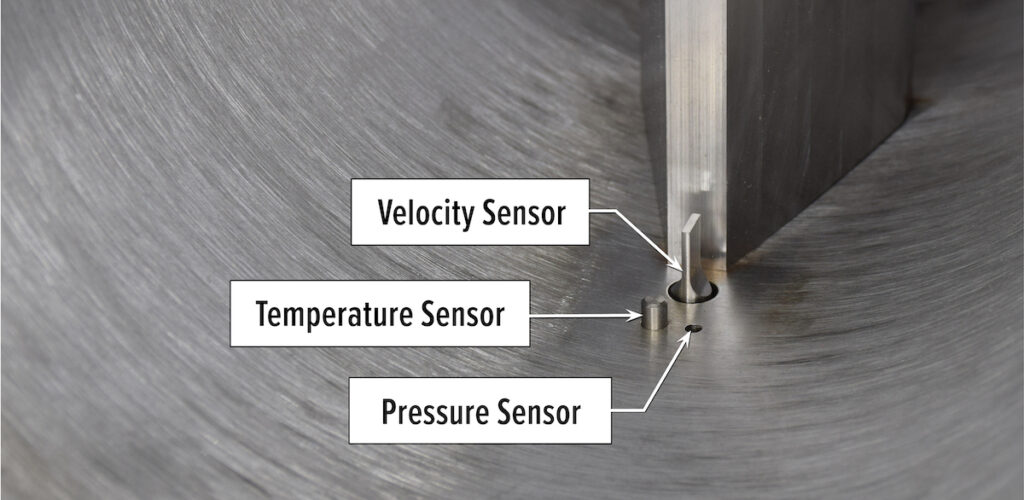

In density compensated mass flow measurement, temperature and pressure measurements are used to calculate fluid density. This fluid density is then combined with volumetric flow rate to calculate a mass flow rate. Both vortex and differential pressure flowmeters utilize this method of mass flow metering.

Reduced installation and maintenance costs

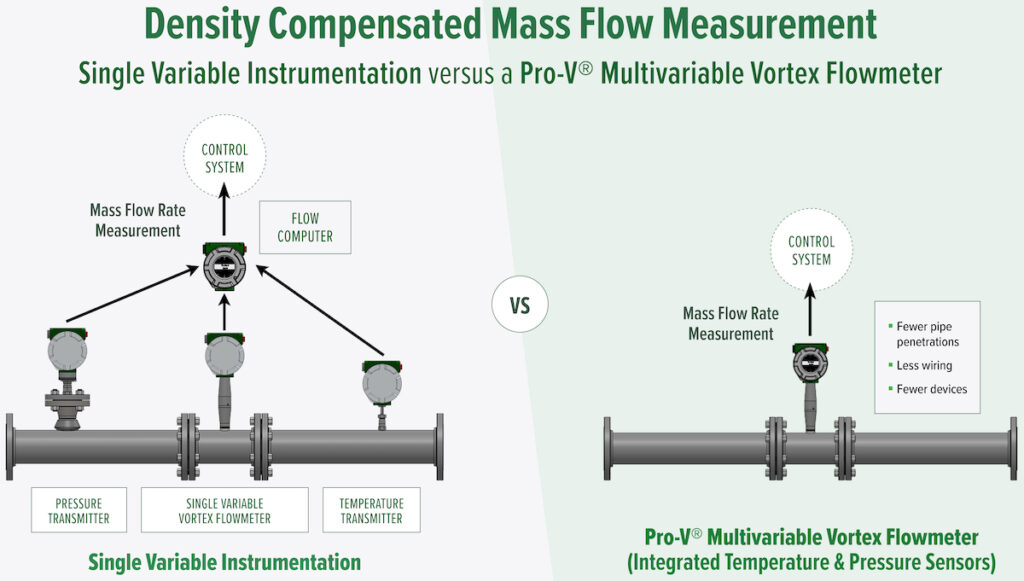

Before the advent of multivariable instrumentation, density compensated mass flow measurement would require a total of four separate instruments. A volumetric flowmeter, pressure transmitter, temperature transmitter, and a flow computer to perform the needed computations. All of these separate instruments have to be installed and maintained throughout their useful lives. Installing and maintaining four separate instruments requires an extraordinary amount of work and adds a high degree of complexity to the measurement.

Fewer devices, pipe penetrations, and potential leak points

Multivariable instrumentation groups these sensors into a single instrument. This grouping reduces the number of devices and the amount of wiring required. Multivariable instrumentation also reduces the number of pipe penetrations and potential leak points.