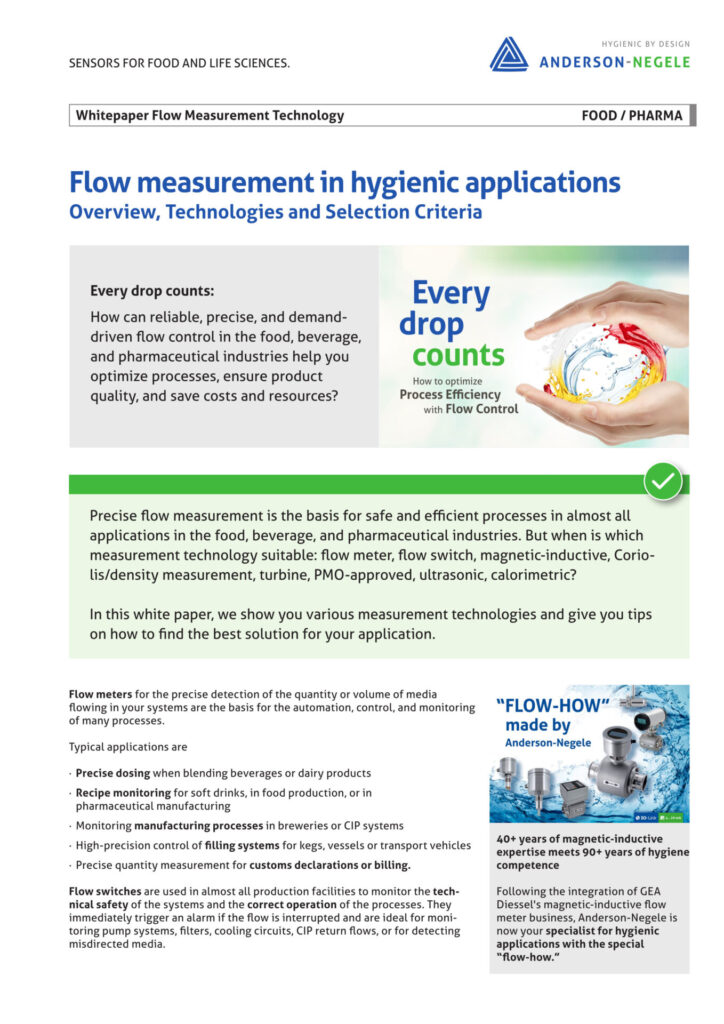

Precise flow measurement is the basis for safe and efficient processes in almost all hygienic applications. But when is which technology the best fit: flow sensor or flow switch, magnetic-inductive, Coriolis density measurement, turbines, ultrasonic or calorimetric?

In a new whitepaper, the experts from Anderson-Negele present and discuss various measurement technologies and give you tips on how to find the best solution for your application. It also includes a comprehensive overview of applications in the food and beverage industry and the suitability of the sensors for each of those.

Flow meters are used for the precise detection of the quantity or volume of media flowing in your systems, and are the basis for the automation, control, and monitoring of many processes.

Typical applications are

- Precise dosing when blending beverages, dairy or life science products

- Recipe monitoring in food and beverage or in pharmaceutical manufacturing

- Monitoring manufacturing processes in production or CIP systems

- High-precision control of filling systems for kegs, vessels or transport vehicles

- Precise quantity measurement for customs declarations or billing.

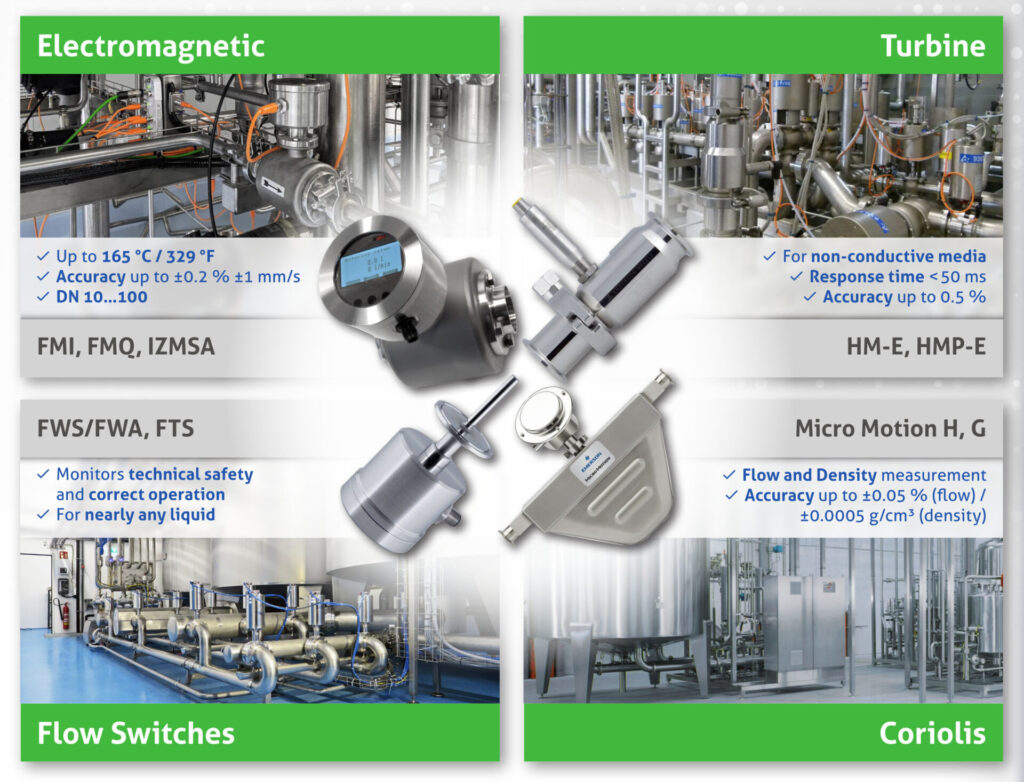

Flow switches are used in almost all production facilities to monitor the technical safety of the systems and the correct operation of the processes. They immediately trigger an alarm if the flow is interrupted and are ideal for monitoring pump systems, filters, cooling circuits, CIP return flows, or for detecting misdirected media.

The whitepaper also provides an overview of the technologies which are available on the market, a matrix with possible applications, and the recommended technology for each of these applications in dairies, breweries, the beverage or the pharmaceutical industry. A list of additional parameters and media properties completes the criteria for the selection of measurement systems.

Selection criteria for flow measurement systems

- Measurement accuracy: Depending on the application, the required measurement accuracy for the flow rate can vary significantly. For example, mixing or dosing products may require a measurement accuracy of ±0.2 %, while ±0.5 % may be sufficient for filling storage tanks, and a value of ±10 % may be adequate for measuring wastewater quantities. Since this significantly influences the purchase price of the devices, it should be determined in advance what measurement accuracy is actually required in the process.

- Measurement accuracy: Depending on the application, the required measurement accuracy for the flow rate can vary significantly. For example, mixing or dosing products may require a measurement accuracy of ±0.2 %, while ±0.5 % may be sufficient for filling storage tanks, and a value of ±10 % may be adequate for measuring wastewater quantities. Since this significantly influences the purchase price of the devices, it should be determined in advance what measurement accuracy is actually required in the process.

- Media consistency: Electro-Magnetic or Magnetic-Inductive Devices (MID) require a conductivity >5 μS/cm. If the medium is not conductive, e.g. demineralized water, water for injection (WFI) or oils, Turbine or Coriolis sensors can be used.

- Viscosity (e.g., in dough or paste) or the proportion of chunks (e.g., pieces of fruit in yogurt) are also important. MIDs do not impose any restrictions here, whereas Turbine and Coriolis Meters and Flow Switches are not or less suitable due to their mechanical components in the tubing or reduction of the nominal diameter.

- Quantity preselection: For kegs or transport containers, precise quantity preselection can facilitate automation of the filling process.

- Official measurement protocol: For certain applications, such as customs declarations, customer orders, or transfer of ownership, proof is required by calibration authorities or customers. This can be fulfilled by appropriate systems with calibration capability for official measuring systems. However, since calibration authorities have different requirements, these must be clarified with the responsible authority in each individual case before selecting the measuring system.

- Aggressive media/acids: Measuring systems are exposed to high mechanical or chemical stress due to media or CIP/SIP cleaning processes. All parts that come into contact with media, such as measuring tubes, coatings, electrodes, or process connections, must be checked for resistance to these influences.

- Installation conditions: The different measuring systems have different process connections, installation dimensions, inlet and outlet lengths, electrical connections, and maximum operating pressures. For processes with high vibrations or high media temperatures, remote devices can be beneficial, as the sensitive electronic components can be mounted at several meters distance. Mobile sensor units can be a cost-saving option for applications where, for example, several storage or maturation tanks are filled or emptied one at a time.

- Pig cleaning: Only Electro-magnetic devices are suitable for this purpose, as they have the same pipe diameter as the process lines and do not have any components inside the tubing.

- PMO Certification: PMO M-b approval for meter-based timing applications in pasteurization processes can be important in the U.S.A.

- Density measurement: If density (e.g., concentration, Brix, Plato, proof, or Baume value) is required in addition to volume, Coriolis meters that combine flow and density measurement in a single device are recommended.

What are the measuring principles for flow control?

The most important product category for hygienic applications is Electromagnetic / Magnetic-Inductive Flow Meters (Mag Meters). This product line includes a wide range of different sensor types with a big diversity of variants and technical specifications.

For non-conductive media that cannot be measured with Mag Meters, Turbine Flow Meters are the suitable alternative.

Another system works with the Ultrasonic measuring principle and can be used as a flow meter with sufficient accuracy for many applications or as a flow switch.

Finally, there are Calorimetric devices that, being pure flow switches, only transmit an I/0 signal.

Anderson-Negele offers devices developed and manufactured in-house for all these areas. They are supplemented by Micro Motion brand Coriolis devices for flow and density measurement. These were added to the Anderson-Negele product portfolio as part of a distribution partnership with Emerson, one of the world’s leading suppliers of such systems.

Due to the wide range of requirements, all devices are available in many configurations and with additional options. This enables the best solution for almost every purpose and application.

The product range comprises the following flow sensor types:

- FMQ (Magnetic-Inductive): Compact, robust, reliable – The affordable all-rounder for almost all applications, with IO-Link and max. process temperatures up to 165 °C (329 °F)

- FMI / IZMAG (Magnetic-Inductive): The benchmark for accuracy, reliability, and durability, with powerful electronics and a measuring accuracy of ±0.2% ±1 mm/s

- IZMSA (Magnetic-Inductive): The specialist for dosing and filling applications, integration in official measuring systems possible (acc. to 2014/32/EU with Certificate TC 7520)

- IZMS (Magnetic-Inductive): PMO M-b approved (U.S.A.) for meter-based timing applications in pasteurization processes.

- HM / HMP (Turbine): The solution for non-conductive media with extremely fast response time <50 ms and two-piece stainless-steel housing for easy cleaning and vibration resistance

- FWS/FWA (Ultrasonic): Flow switch and Flow meter with measuring accuracy ±10%, ideal for all media like drinking water, fruit juice (unfiltered), milk, emulsions, CIP media

- FTS (Calorimetric): Flow switch with pulse measurement method, also suitable for demineralized and highly filtered media such as cola and other soft drinks, filtered beer, demineralized water, and for media in pressure lines

- Micro Motion (Coriolis / in partnership with Emerson): One device for various applications – mass and flow measurement, density measurement of liquids and slurries