Many plants and biowaste processes, such as those for landfill solid waste and municipal wastewater, produce a mixture of combustible methane and carbon dioxide gases with traces of nitrogen, oxygen and other gases. These “greenhouse gases” can be disposed of by flaring or recovered as a green fuel source for cogeneration engines to produce electric power for onsite plant power needs and/or sent to the power grid.

The accurate, repeatable measurement of these gases under variable flows throughout the system provides operators with information on the amount of gas being processed in order to optimize effectiveness, for reporting to environmental agencies and for carbon credit programs. Accurate gas flow measurement requires performance under challenging conditions such as wet and/or dirty gas, mixed composition gases, potentially explosive installation environments, wide variations in flow rates, seasonal swings in gas and ambient temperatures, and larger line sizes.

Flow meters that perform accurately and safely under these conditions must meet several requirements. Their design must be multi-function, providing flow rate, totalized flow data and temperature outputs. They have to be calibrated for methane with mixed gases, require temperature compensation, have no moving parts or orifices that clog or foul, be available with single tap insertion designs and adjust automatically to wide turndowns over a wide flow range, including extremely low flow sensitivity. In addition, they must be agency-approved for use in Division 2 [Zone 2] and often Division 1 [Zone 1] hazardous environments.

Thermal Meters For Waste-To-Energy Cogen Power Systems

The ST51 Flow Meter is ideal for solid waste landfill gas flow measurement. It features a proven thermal dispersion flow sensor available in an insertion-style package that has been developed for use in pipe diameters from 2.5 to 24 inches [63 to 610 mm]. It is specifically designed for the flow measurement of methane-based gases such as biogas, digester gas, landfill gas, natural gas, and for air, compressed air or nitrogen.

This meter is an insertion-style instrument that can be installed into the pipe via a 0.5 or 0.75-inch NPT compression fitting. It features a measurement range from 0.3 to 400 SFPS [0.08 to 122 MPS] with a turndown ratio of 100:1 and with an accuracy of ±1 percent reading, ±0.5 percent full scale. Depending on the configuration, they are suitable for process temperatures from up to 250°F (121°C) to 350°F (177°C) and pressures from 150 psig [10 bar(g)] to 500 psig [34 bar(g)].

They are designed with a no-moving parts, non-clogging thermal mass flow sensor. The ST51 Meter features precision platinum RTD sensors embedded in equal mass small-diameter, all-metal thermowells. Combined with microprocessor electronics and precision calibration, this meter achieves excellent accuracy with a fast response. There is virtually no maintenance required over a long life for an exceptionally low life-cycle cost.

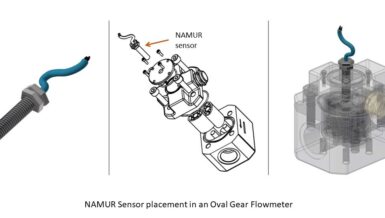

The ST51 Meter’s electronics are housed in a rugged IP67-rated enclosure with dual conduit ports in either NPT or M20 threading. The instrument comes standard with dual 4-20 mA outputs and a 500 Hz pulse output. Optional features available include HART as well as a higher process temperature service range, NAMUR-compliant 4-20 mA outputs and a SIL compliance rating. The transmitter/electronics can be integrally mounted with the flow element (probe) or be remotely mounted to best match the installation requirements.

A DwyerOmega brand, FCI delivers precise flow and level instrument measurement solutions using advanced thermal dispersion technologies. With more than 60 years of experience and the world’s largest installed base of thermal flow meters, flow switches, and level switches, FCI is the trusted expert in flow and level instrumentation.