Why is some laundry detergent blue?

Besides playing an important role in brand recognition and customer appeal, these colored dyes also serve a more functional purpose. White fabrics often lose their color over time, becoming more yellow or grey. The addition of blue coloring and other fluorescing agents adds trace amounts of dye to fabrics, counteracting the discoloration and brightening the fabric. This bluing trick got its start in the 19th century and has been utilized in some form ever since.

Modern blue dyes and fluorescing agents come in extremely high concentrations, so color dosing systems must add in very low doses during detergent production. The high concentration also means that slight variations in dosing can lead to noticeable variations in the appearance of the end product.

Using pumps for color dosing

Dosing and metering pumps are often used to regulate color dosing systems. Under constant temperature and pressure conditions, the displacement of the pump can be used to infer an accurate flow rate. However, fluctuations in temperature and pressure alter fluid properties and therefore decrease the accuracy of flow measurements. Pump wear and tear can also decrease the system’s accuracy and repeatability. While these pumps are often fairly inexpensive themselves, process inefficiency can lead to costly losses.

Coriolis flow meters for color dosing

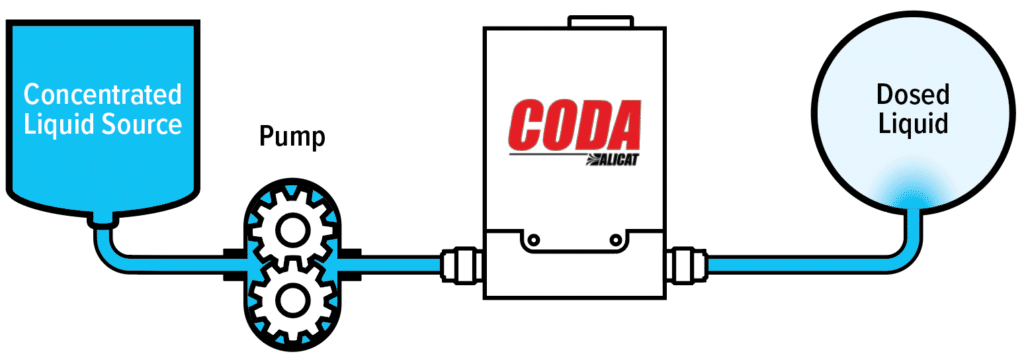

It is now common to find flow meters added into color dosing systems as an extra safety net of process monitoring. The flow meter monitors flow downstream of the pump in the color dosing system, providing real-time feedback to the pump over analog signals or a range of industrial protocols. This automated monitoring of the dosing process minimizes costly process inefficiencies and wasted batches, and ensures consistency in detergent product quality.

Coriolis mass flow technology, in particular, is an ideal solution, providing repeatable, high-accuracy mass flow readings for liquids and gases at very low flows.

Alicat’s CODA-Series of Coriolis mass flow instruments provide further unique benefits to the dosing of colors and fluorescing agents in detergents. When flowing liquids, CODA mass flow meters have accuracy as good as ±0.2% of reading or ±0.05% of full scale (whichever is greater) and repeatability of ±0.05% of reading or ±0.025% of full scale (whichever is greater). Since these instruments are built with inherent insensitivity to external vibrations and disturbances, process disruptions from nearby generators or mechanical actuators are minimized. CODA instruments additionally do not require annual calibration and are available in several highly customizable models, including a more cost-effective version ideal for plant processes requiring multiple parallel units.

Fun fact: A popular method of laundry bluing used into the 1900s involved a product called “Reckitt’s Blue-Bags” which contained one-ounce squares of synthetic ultramarine and baking soda. Before this product was created, clothes were whitened with a blue dye made from finely ground cobalt-containing glass.