But there are a few challenges presented by the current electrolysis process, from varying power input of renewable energy sources to the continuous drive for cost reductions.

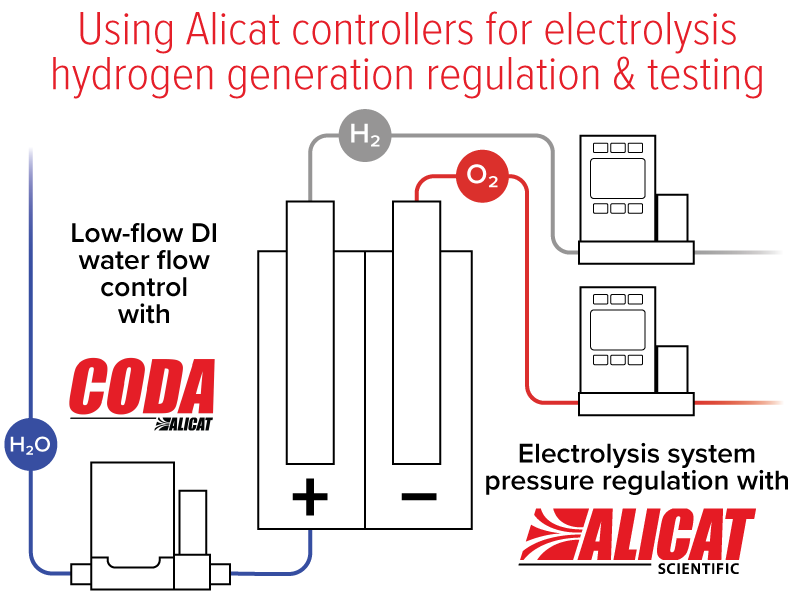

The low flow rates and high water temperatures used in electrolysis make precise system testing and regulation difficult. Using mass flow technologies that measure low flow with high accuracy in high temperature conditions can ensure the success of your process. Coriolis mass flow instruments are capable of measuring and controlling mass flow rates as low as 0.08 g/h at temperatures up to 70°C.

Ensuring electrolysis efficiency also requires fast and responsive pressure control to maintain the differential or balanced pressures between oxygen and hydrogen. Depending on the scale of the process and methods used, factors such as high temperatures, pressures, and gas humidity can make this a bit tricky. But a multi-orifice back pressure regulator is able to regulate electrolyzer system pressure over a wide range (10,000:1 turndown) while remaining unaffected by moisture.

If you have questions about solutions for electrolyzer systems, contact our applications engineers to find a solution for your process needs.