The Challenge – Measuring Sour Gas Flow in High-Pressure Pipelines

In natural gas and crude oil production, both gas lift and gas injection play essential roles. Gas lift enhances oil recovery by injecting gas into production wells, reducing hydrostatic pressure to improve fluid flow. These systems rely on precise flow measurement to optimise efficiency, and evaluation of existing Differential Pressure (DP) meters or their replacement with advanced ultrasonic technology can provide significant operational benefits.

Meanwhile, gas injection – used for reservoir pressure maintenance and secondary oil recovery – demands flow meters capable of withstanding extreme conditions, including very high-pressure environments and thick-walled pipelines. This challenge is further compounded in sour gas applications, where permanent installations of ultrasonic flow meters can be highly beneficial due to their durability, accuracy, and ability to operate safely in harsh conditions.

A major gas condensate field operator in Kazakhstan faced a significant challenge in Unit 2 of its high-pressure gas injection system. The reinjection process involved handling sour gas (with 4% H₂S content) at pressures up to 550 bar. A previously installed clamp-on ultrasonic flow meter from another provider failed to perform reliably, prompting engineers to seek a more effective solution.

The Flexim Solution for Gas Injection and Gas Lift

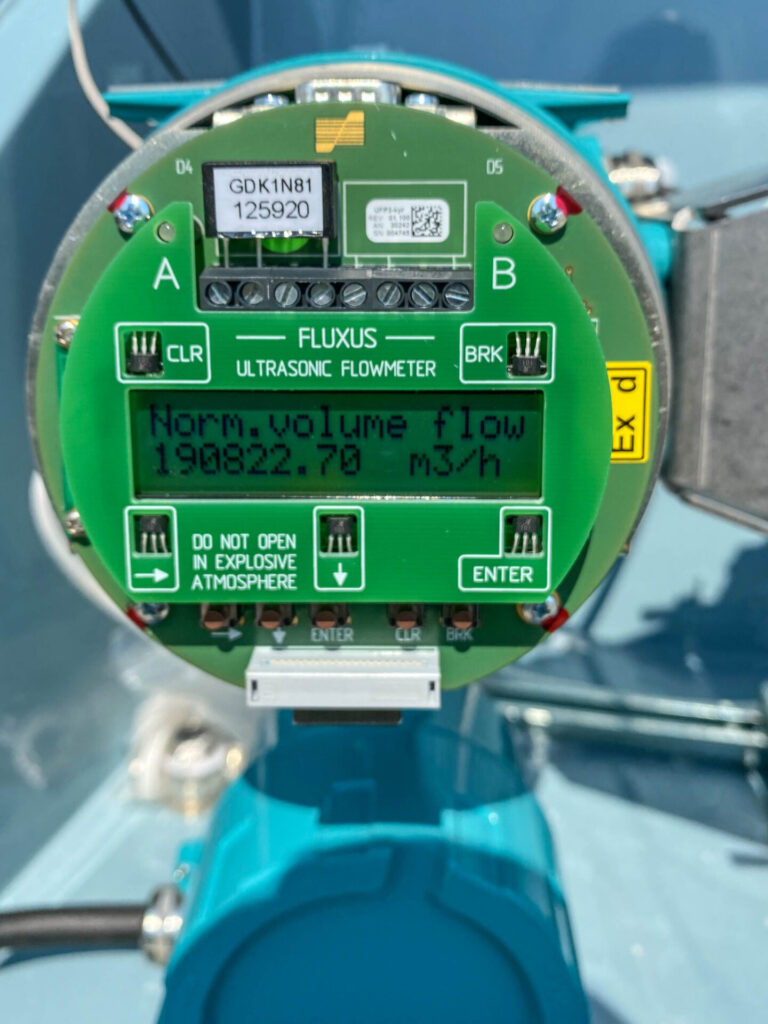

After evaluating the challenges, Emerson proposed the Flexim ultrasonic flowmeter equipped with K transducers. The solution was supported by references from similar high-pressure applications, including a successful installation in Kazakhstan’s Kashagan field.

Despite initial scepticism due to past failures, the engineering team proceeded with the installation. The flow meter demonstrated flawless performance, delivering precise and reliable measurements across the entire operating range. This success validated the capability of clamp-on ultrasonic flow technology even in extreme environments, ensuring measurement accuracy and safety in high-pressure sour gas pipelines.

Also, in gas lift operations where accurate gas flow rates are critical, Flexim technology presents an opportunity for operators to evaluate and replace existing DP meters. Many DP meters in service may suffer from drift, degradation, or suboptimal calibration, leading to measurement

errors. Conducting service jobs for evaluation and replacement with ultrasonic meters can lead to increased efficiency and production optimisation.

Customer Satisfaction and Future Implementation

Following the installation, the engineering team expressed complete satisfaction with the flow meter’s performance. The unit operated in full accordance with declared metrological characteristics, reinforcing confidence in Flexim technology. As a result, the operator not only acknowledged the success of the solution but also placed an order for additional flow meters.

Emerson’s advanced Flexim ultrasonic flow measurement technology has proven its reliability in both gas lift and gas injection applications, overcoming the limitations of traditional instruments. By enabling service jobs for DP meter evaluation and replacement in gas lift systems, and offering permanent installations for high-pressure sour gas injection lines, clamp-on flow measurement is setting a new standard for precision in challenging oil and gas environments. As more industry operators recognise these advantages, the adoption of this innovative technology is poised to expand, ensuring efficiency, safety, and accuracy in demanding applications.