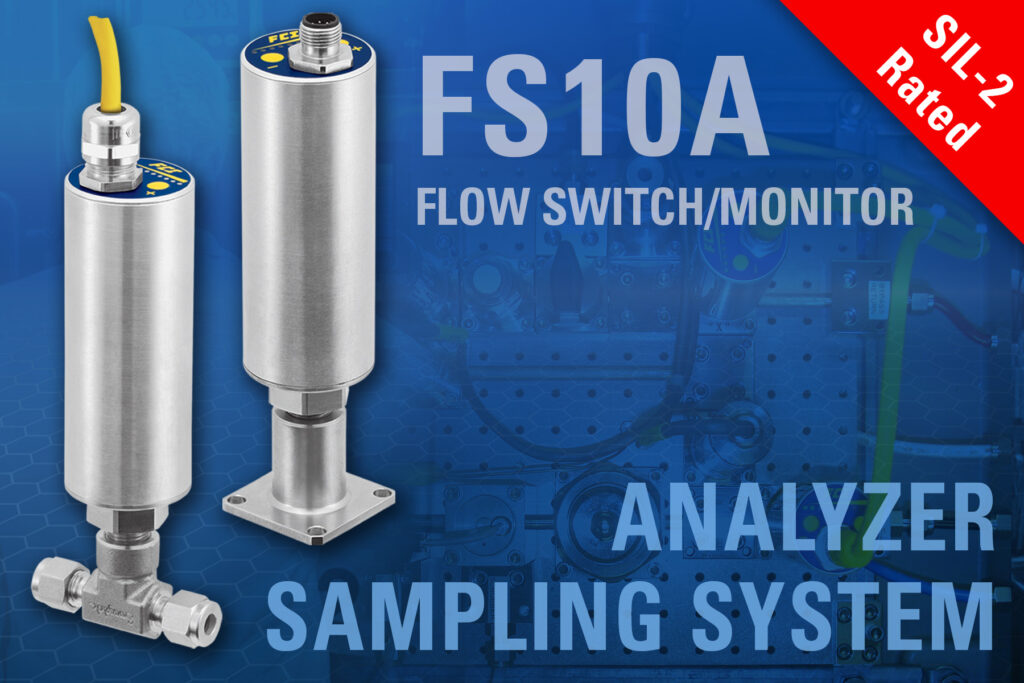

The advanced FS10A Analyzer Flow Switch/Monitor is a sophisticated universal flow switch monitor that is specifically designed for liquid and gas process analyzer sampling systems. This compact, responsive switch features a highly repeatable sensor that installs into a standard tube tee fitting or a SP76 (NeSSI) modular manifold.

The control of many toxic and/or combustible liquids and gases requires continuous monitoring of analyzers to ensure safe, effective use to protect employees and assure end-product quality. Validation of uninterrupted flow to the analyzer alerts system operators should the analyzer fail to measure or operate for any reason, such as blocked sample tubes, stuck valves or any other number of potential issues.

With itss proven thermal flow measurement technology, the FS10A Analyzer Flow/Switch Monitor is designed with proprietary equal mass sensing to achieve outstanding sensitivity and repeatability. Its wetted parts are corrosion-resistant 316L stainless steel with Hastelloy C-22 sensor tips. This unique flow sensor has no moving parts to foul, clog or maintain, which ensures continuous reliability and virtually no maintenance. There are no cavities, orifices or dead-legs to trap or contaminate samples, which preserves sample integrity and faster sampling times.

The Model FS10A features state-of-the-art electronics that are packaged in a rugged, fully-sealed, stainless steel housing that provides it with exceptional protection and long-life under all process conditions. The electronics package can be integral-mounted with the sensor element, resulting in a unibody, self-contained unit or the electronics can be remote-mounted from the sensor.

The FS10A Analyzer Flow/Switch Monitor’s remote configuration is Div 1/Zone 1 FM approved for hazardous environments. This configuration is useful when the sensor’s installation area is

Verifying Analyzer Liquid or Gas Flow

subjected to high temperatures or for mounting to the front panel of the analyzer, placing its display in a more convenient location for easy viewing.

Plant technicians will appreciate that this instrument is designed with an easy-to-read top-mounted, flow rate monitoring LED array. It provides a visual indication at a glance of the operational status of the proper flow rate to the analyzer or sampling system, or that an alarm/trip point has occurred. The switch’s set-point is conveniently user-settable via two push-buttons accessible at the top of the unit or via the RS232C I/O port.

Developed for use with nearly all types of process and emissions sampling systems, the FS10A Analyzer Flow/Switch Monitor is ideal for use with gas chromatographs (GCs), mass spectrometers, optical spectrometers, photometers and others. Standard configurations will accommodate standard 1/4, 3/8 and 1/2 inch process connections, as well as 1/8 inch injection tube adapters or SP76 (NeSSi) modular manifold.

Depending on the tube size, the FS10A Analyzer Flow Switch/Monitor operates over a wide flow range in water/liquids: from 0.70 cc/min to 750.00 cc/min (0.01 GPH to 12.00 GPH); and in air/gas: from 10 cc/min to 100,000 cc/min (0.02 SCFH to 200 SCFH). It accommodates wide turndowns with a ratio from 5:1 up to 100:1.

The Model FS10A features multiple outputs for user flexibility. They include: a 1A relay settable for NO or NC operation and which is user settable for failsafe, hysteresis and/or time delay, and a 4-20mA analog output for trending.

In addition to its SIL-2 rating, the Model FS10A features various required global hazardous area operations approvals for safety and peace-of-mind, including FM, FMc, ATEX/UKEX, and IECEx for use in Div 2/Zone 2 environments. Other compliances include CE Marking, CRN, EAC/ TR CU, KC certification and RoHS.

A DwyerOmega brand, FCI delivers precise flow and level instrument measurement solutions using advanced thermal dispersion technologies. With more than 60 years of experience and the world’s largest installed base of thermal flow meters, flow switches, and level switches, FCI is the trusted expert in flow and level instrumentation.