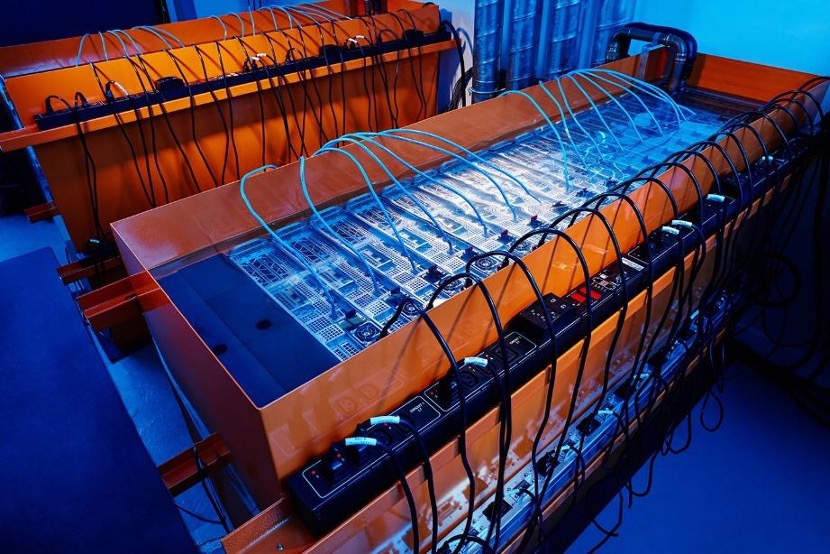

Liquid Cooling is a way of dissipating heat from electronic devices. It absorbs the heat generated by the device bypassing the cooling medium (which may be water or other coolant) through the radiator of the electronic device, taking the heat away, thereby reducing the temperature of the device.

Liquid cooling systems are increasingly used in various industries, including HPC, data centers, industrial machinery, power batteries, energy storage batteries, etc. due to their superior thermal management efficiency compared to traditional air cooling methods.

XY-TEK TGD series ultrasonic flow sensors play a crucial role in optimizing the performance of these liquid cooling systems by providing reliable and accurate flow measurements.

Industry Challenges

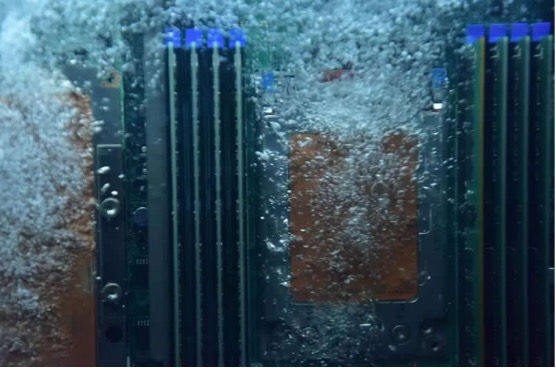

Uneven distribution of coolant flow and abnormal coolant in and out will affect the eficiency ofliquid cooling.

Coolant may change its physical properties with changes in temperature, pressure, and concentration, affecting the flow meter measurement accuracy.

Solid particles or contaminants may exist in the coolant, which may cause blockage or wear in the flow meter, there by affecting the performance of the flow meter and causing the liquid cooling system to fail.

Application Overview

- Connect the coolant pump to monitor the coolant inlet flow.

- Monitor the cooling liquid outlet flow, transmit the data to the cooling system management unit, and adjust the operating frequency of the coolant pump according to the actual outlet of the flow.

- Abnormal changes in flow rate may indicate pump failure or tubing blockage.

- Overall monitoring of the coolant flow rate to ensure the coolant can flow continuously and evenly through the cold plate, which can effectively calculate the cooling effect of the system and avoid local overheating.

Application Highlights

- High Accuracy – TGD series sensors provide precise flow measurements, not affected by changes in wall thickness and pipe materials.

- High Accurately – Accurately measure the flow rate of ultrapure water or coolant up to 1000L/min.

- Operation and Maintenance – Ultrasonic measurement, no internal blockage, no pressure loss, high media tolerance, and long-term protection performance.

- Real-time Flow Data Display – The TGD series ultrasonic flow sensors with a built-in digital screen, offer real-time flow data display, enabling operators to monitor flow rates and identify any anomalies quickly.

- Sensor data collection – Combined with flow sensor data, users can establish a liquid cooling temperature control model to achieve more thermal management efficiency.

- Measure a variety of coolants – Water, Ultrapure water, Glycol-Water Mixtures, Refrigerants, Hydrous media Mineral oil, Edible oils, and other oils of high and low viscosity.

- Enhanced System Efficiency – By ensuring optimal flow rates and coolant distribution, TGD series ultrasonic flow sensors help improve the overall efficiency of liquid cooling systems, leading to energy savings and extended equipment life.