In this video, Tumi shares her knowledge from her time in the cosmetics industry and explains what a Hot Process Emulsion is and how the Silverson homogeniser enables the formation of high-quality creams and lotions. Learn about the different phases, the ingredients in each phases and mixing them at temperature.

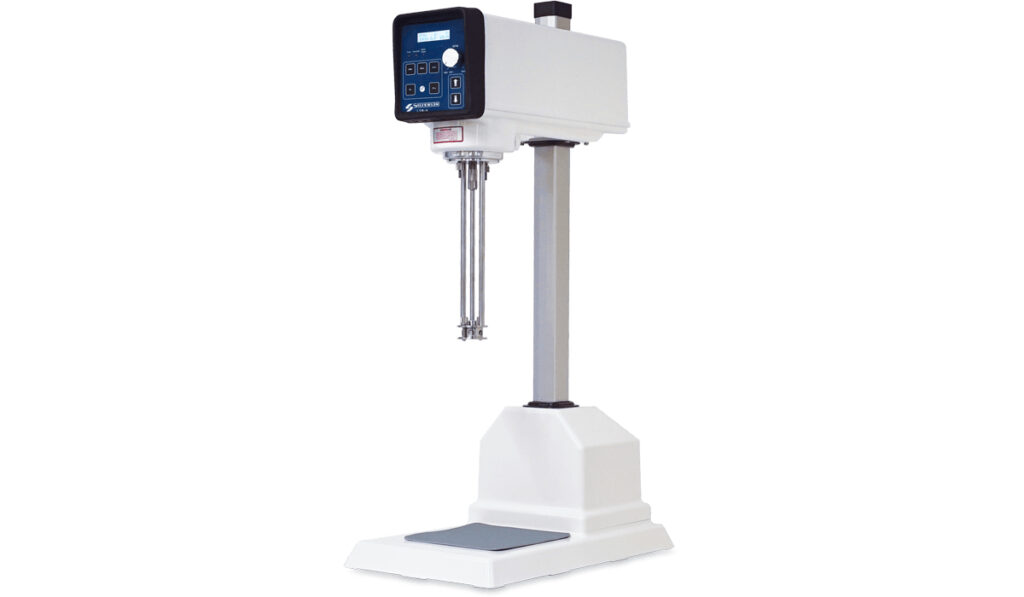

The emulsion is created using a Silverson multi-purpose Laboratory mixer. Silverson Laboratory mixers are used for a variety of mixing processes from simple liquid/liquid blending, forming emulsions and reducing particle size to more complex mixing applications. They are ideal for all routine laboratory work, research and development, QA analysis and small scale production.

The ‘standard’ L5M-A model is the latest development in high shear laboratory mixing. The advantage of a Silverson over simple agitators and stirrers stems from the specially designed rotor/stator workhead. Silverson laboratory homogenisers deliver fast, efficient, and aeration-free mixing through the application of intense high shear—minimizing processing time and often eliminating the need for auxiliary pumps. Inside the workhead, a three-stage mixing process precisely breaks down particles and droplets to produce stable, uniform emulsions and dispersions. The high speed rotation of the rotor blades draws materials into the workhead. Centrifugal force propels the product outward into the narrow gap between the rotor blades and the inner wall of the stator, where it undergoes a precision milling action. This stage begins the breakdown of particles and droplets to a smaller, more uniform size. The product is then forced at high velocity through the stator’s perforations, subjecting it to intense mechanical and hydraulic shear. As the mixture exits through the outlet, fresh material is continually drawn into the workhead, progressively reducing globule or particle size, ultimately delivering a completely homogeneous and uniform final mixture.

With its integral tachometer, ammeter and programmable timer, the L5M-A laboratory homogeniser offers a level of instrumentation invaluable in applications where process validation and repeatability are required. The L5M-A can also be supplied with a temperature probe which can be invaluable in this application, as seen in this video.

As Tumi explains, temperature plays a critical role, not only in combining the oil and water phases, but also in determining when to add temperature-sensitive components. Ingredients such as fragrances, colorants, preservative systems, and extracts must be incorporated below a specific threshold to maintain their efficacy and stability. See how the Silverson Laboratory mixer is able to maintain uniform mixing throughout, delivering a consistent, stable emulsion.