The Pursuit of Beauty

People have been manufacturing cosmetics since ancient times. The Romans were especially fond of skin creams, using ingredients such as beeswax and olive oil mixed with rose water to create their lotions. But, since oil and water don’t readily mix, they had to learn how to homogenise and emulsify disparate ingredients. Then and now, the end product needed to be uniform, creamy and appealing. While the Romans had to achieve these results manually, it’s a different story now.

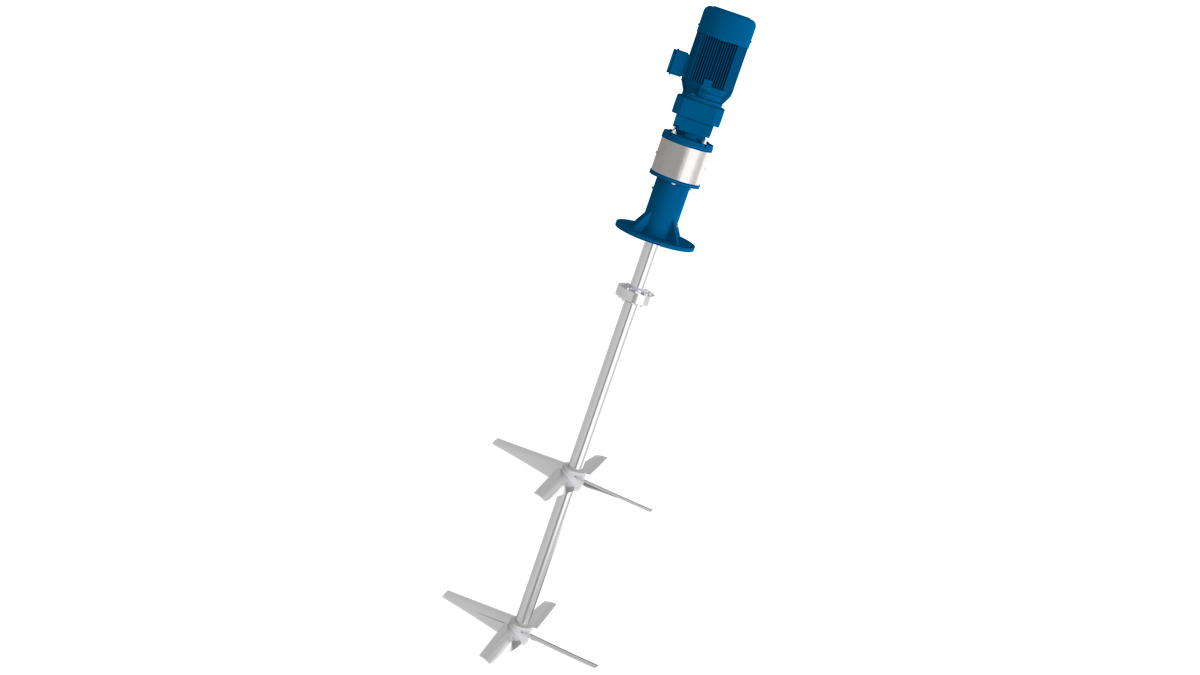

Today, manufacturers use industrial-scale mixing equipment to produce well-blended, safe cosmetics with the perfect consistency, colour, scent, stability and mix of ingredients.

Modern Challenges

Today’s consumers are a demanding crowd. For a start, they expect consistency. The last few swipes of lipstick need to look just as vibrant as the first few did. They’re also searching for the finest quality. Does it last? Does it resist running? Will it continue looking fresh, or wipe off too easily? Are the ingredients good for my skin? To achieve these lofty goals, cosmetics manufacturers have spent years devising carefully guarded formulations.

These complex formulations present numerous challenges to manufacturers. Depending on the formulation of the final product, the production of cosmetics may involve adding dry, powdered ingredients to liquids, or emulsifying immiscible liquids, such as oils and water-based ingredients, such as fragrances and other key ingredients.

There are specific requirements and challenges in the manufacturing of cosmetic creams and liquids. To achieve smooth, consistent texture, colour and other characteristics, it’s vital that all ingredients undergo the kind of mixing that can only be achieved by advanced technology. Indeed, some of today’s products are only possible using submicron processing, a process by which constituents are reduced in size to vanishingly small particles.

It’s essential to incorporate the gums and polymers without creating agglomerates or “fisheyes”. Manufacturers are aiming for fine dispersing of pigments in the re-circulation loop, and the setting of final, high-viscosity water/silicone emulsion with a single pass before packaging. Not only that, but all of these processes must occur under controlled, consistently reproducible, completely hygienic conditions. After all, health and safety are at stake, and the regulators are paying attention.

The potential pitfalls involved are numerous. However, modern manufacturers possess the distinct advantage of having access to high-tech equipment – cosmetic mixing machines carefully engineered to achieve high shear mixing.

Technology to Tackle the Challenges

Efficiency is the goal, and the proper equipment for making cosmetics can help you achieve it. For example, Quadro® Liquids’ industrial personal care mixers minimise undesirable results, such as the development of clumps, lumps, and fisheyes, when mixing powders into liquids.

Our high shear industrial mixers reduce batch times, maximise the use of raw ingredients, help reduce energy expenditures and minimise waste. This means that you can focus on delivering the highest quality final product. High speed industrial mixers are ideal for creating homogenous mixtures and emulsifications, even from traditionally difficult-to-blend materials. In high shear mixing, a high-speed rotor applies enough velocity to generate shear; this reduces the size of particles to the point where they can be more easily combined with other substances.

Thanks to our advanced technology, we minimise the risk of over-shearing certain ingredients to achieve uniform consistency and thorough dispersion. We sidestep this risk by significantly improving mixing efficiency from the very start of the mixing process. Of course, your mixing operations must also be capable of achieving stable emulsions when that’s the goal, as well as minimising waste and optimising the ability of operators to clean equipment as needed.

Quadro® Liquids is your go-to cosmetics manufacturing equipment supplier, with a full line of superior cosmetics mixers to choose from, including:

- inline powder disperser

- high shear cosmetic homogenizer and wet mill

- inline cosmetic emulsifier mixer

Quadro® Technology Provides the Solution

The personal care and cosmetics industry depends on sophisticated industrial personal care mixers to achieve products that offer uniformity, sensual appeal, shelf stability, pleasing texture, and consistent colour and fragrance.

At Quadro®, we specialise in the design, manufacture and servicing of superior, industry-leading industrial cream mixers. Our cream-making machine for cosmetics excels at powder incorporation and dispersion into liquids, in addition to liquid-into-liquid mixing and homogenizing. We are proud to supply industry-leading cosmetic and personal care mixing equipment to the world’s leading cosmetics and cosmeceutical manufacturers.

To learn more about our world-class machinery, contact us here, call us or simply fill out our online form to request a quote.