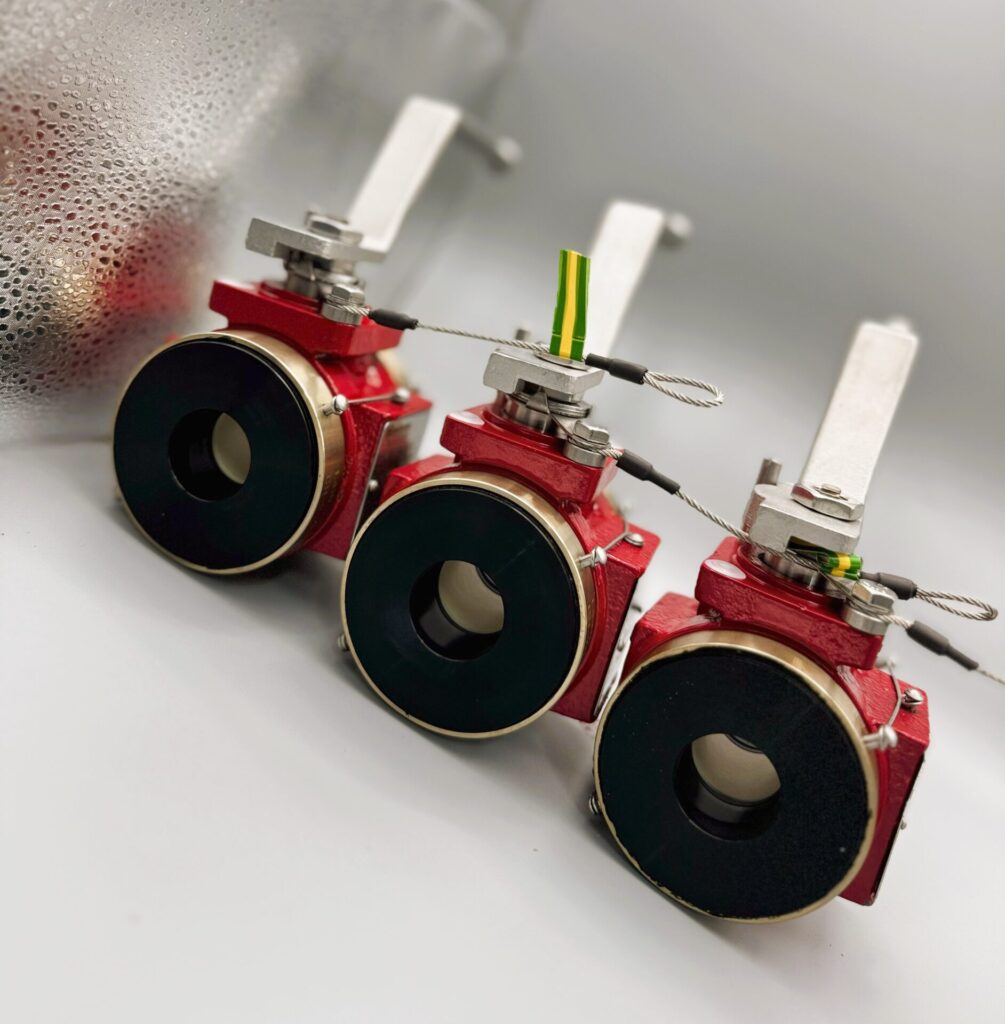

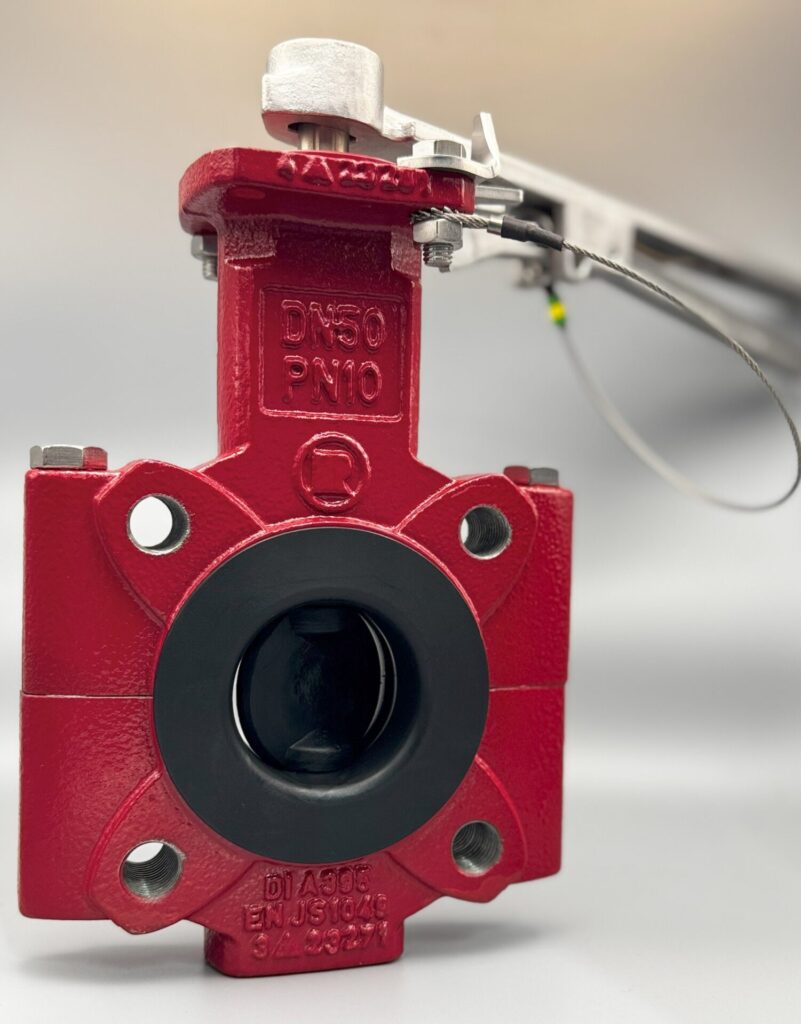

PFA-L: The Black Shield Against Explosion Risks

PFA (Perfluoroalkoxy) is a high-performance plastic belonging to the fluoropolymer family. It offers exceptional chemical resistance, high thermal stability, and non-stick properties. The conductive variant of PFA contributes to safety by dissipating static electricity, thus preventing the risk of sparks or explosions caused by electrostatic discharges. Richter’s valves and pumps with plastic linings are specially developed for demanding industrial applications with corrosive media. The conductive PFA lining is particularly important in environments where flammable or explosive materials are processed.

Precision Through Transfer Molding Process

The incorporation of black conductive plastic is done using the transfer molding process. This process is a special technique for manufacturing components, where molten plastic granulate is transferred into a closed mold under pressure and heat. This method is often used for processing thermoplastic and thermosetting plastics that have specific requirements for strength, dimensional accuracy, and material properties. Compared to the classic injection molding process, transfer molding is characterized by particularly high precision and uniform material distribution. Due to this process, a minimum material thickness of 3.5 mm is guaranteed. The result: valves and pumps that meet the highest standards and work reliably in every application.

FDA Compliance

Another crucial advancement is the FDA compliance of the products. This ensures that the materials and products meet the strict requirements of the US Food and Drug Administration. This is particularly important for applications in the pharmaceutical and biotech industries, where the highest safety and purity standards are required. FDA-compliant materials are characterized by their durability and the ability to not release harmful substances into the products.

TA Luft Certification

Additionally, Richter’s products are certified according to the latest TA Luft (Technical Instructions on Air Quality Control). This certification ensures that the valves and pumps comply with strict emission limits, contributing to environmental and human health protection. The TA Luft certification is a sign of the high quality and reliability of the products and ensures that they meet the highest standards and work safely and efficiently in demanding environments.

By combining FDA compliance, conductive PFA, and TA Luft certification, it is ensured that the products not only meet the highest safety standards but also work reliably and efficiently in the most demanding environments.