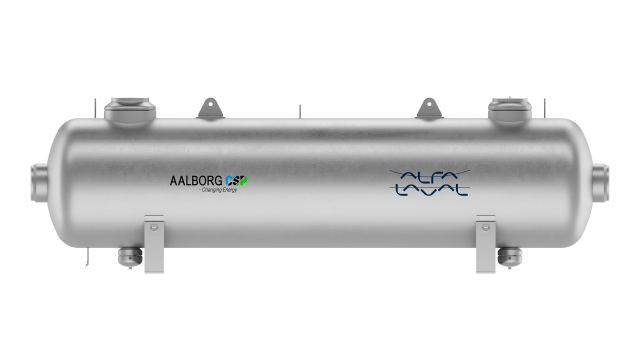

Alfa Laval Aalborg Header-Coil A/S, a joint venture between heat exchanger manufacturers Alfa Laval and Aalborg CSP, has launched its first product in energy storage. The header-and-coil heat exchanger is specifically designed for use in large-scale thermal energy storage systems, offering high thermal efficiency, a compact footprint, and high reliability under cyclic operating conditions.

Designed for cyclic operation

The fully welded header-and-coil design features a unique serpentine tube configuration that provides a large heat transfer surface in a compact footprint. Combined with a tube-shaped header, the serpentine tubes provide flexibility to absorb thermal expansion during cyclic operation, ensuring reliable performance over time.

Tailored for thermal energy storage

Header-and-coil heat exchangers also handle high temperatures and pressures, making them ideally suited for thermal energy storage systems with intermittent operation – for example molten salt-based systems.

“With the header-and-coil technology, we are introducing a solution that addresses the specific challenges of thermal energy storage,” says Alasdair MacIver, Head of Energy Storage at Alfa Laval. “The fluctuating nature of renewable energy sources like wind and solar often leads to fatigue issues in conventional heat exchangers. Our unique design overcomes this, offering high capacity, compact size, and unmatched reliability. We are convinced it will be a valuable asset for system builders developing next-generation sustainable energy infrastructure.”

Available as complete systems

Header-and-coil heat exchangers can function as economizers, evaporators, superheaters, and reheaters. They are available either as individual components or as complete, fully customized steam generation systems, including all necessary heat exchangers, a steam drum, and piping. Based on natural circulation, these systems ensure stable operation with low OPEX and CAPEX.