This requires precise and robust level measurement technology. UWT offers a portfolio of sensors specifically devised for the industry’s needs. These solutions are hygienically designed, durable, and can be easily integrated into existing production environments.

Strict standards throughout the entire process chain

The food and beverage industry is one of the most demanding sectors worldwide. From the delivery and sorting of raw materials to processing, maturation, filling, packaging and logistics – every stage must comply with the highest standards.

Hygiene regulations, product safety, traceability and sustainability are just as important today as energy efficiency and digital integration. Additionally, the variety of media used is extensive – ranging from free-flowing powders to viscous liquids, from sensitive bulk materials to chemically active additives.

Aseptic applications, such as in the production and filling of dairy products, plant-based drinks or infant formula, also impose particular demands on the measurement technology employed. Hygienic design, CIP/SIP compatibility and certified materials are essential to ensure a completely sterile process environment.

Tailored sensor technology – reliable solutions for every application

To meet the diverse requirements of the industry, UWT offers a comprehensive portfolio of certified, high-performance sensors – specifically developed for hygienic processes and a wide range of material properties.

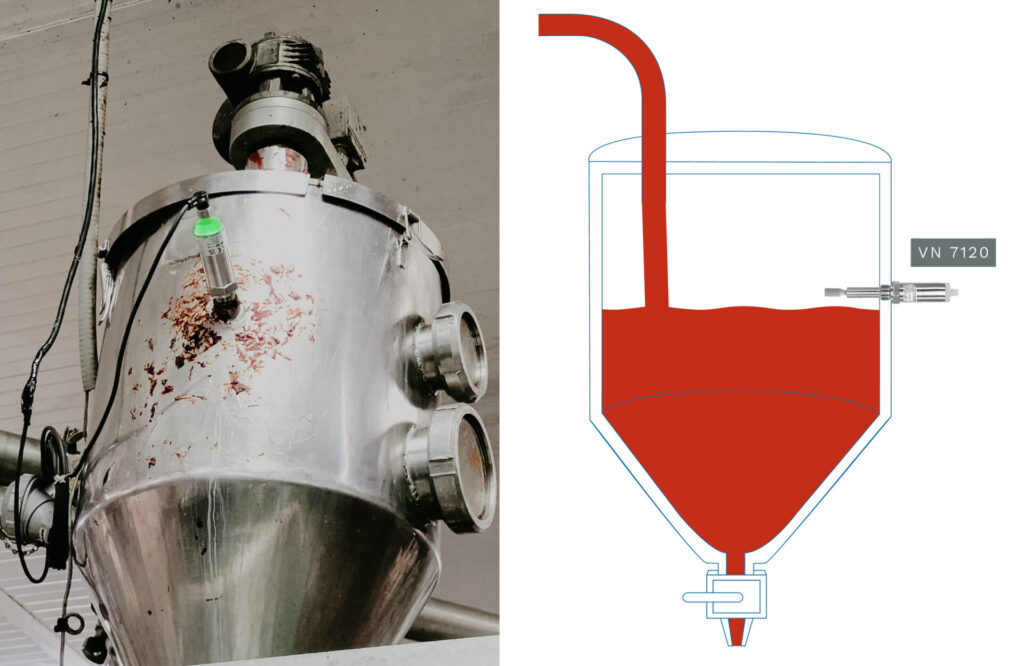

Vibrating fork – Vibranivo® VN Series

Versatile for use in bulk solids and liquids – from dusty powders to pasty media:

VN 1 / VN 5: For applications in all types of solids, including extreme process conditions or interface detection.

VN 2 / VN 6: For fine-grained and powdery materials.

VN 4: For dry, free-flowing bulk solids.

VN 7: For liquids as well as viscous and pasty media – compact, hygienic, and CIP/SIP-capable.

Vibration rod – Mononivo®

Optimal level detection for powders prone to bridging as well as coarse-grained granulates. Also suitable as a backflow detector in pipes and shafts – compact, robust, and reliable in operation.

Rotary paddle switch – Rotonivo®

Mechanically robust solution for free-flowing solids such as flour, sugar, coffee or rice – optionally available in a hygienic version with EHEDG-compliant design.

Capacitive Sensors – Capanivo® Series

Reliable level detection in bulk solids, liquids, pastes, foams and sludges – even under high temperatures, pressure, and with buildup. Ideal for hygienic applications, optionally available with IO-Link and interface detection.

Guided Radar Sensors – NivoGuide®

Precise, continuous level measurement in bulk solids, liquids, pastes, foams and sludges also with interface detection. With Tri-Clamp connection, ideally suited for hygienic processes in the food and beverage industry.

Non-Contact Radar Sensors – NivoRadar®

Ideal for hygienic processes without media contact. The NR Series provides high-resolution, continuous level measurement of liquids and bulk solids – even under challenging process conditions such as steam, condensate, or heavy dust. With its hygienic antenna and various hygiene connections, the NR 8400 is the ideal solution for use in the food industry.

Process monitoring along the entire production chain

From the intake and storage of raw materials to mixing and heating processes through to maturation phases such as in yoghurt or beer production and final filling, precise level sensors play a key role in ensuring process stability, consistent product quality and proactive production planning.

Your Benefits with UWT:

- Hygienic sensor technology for CIP / SIP applications

- EHEDG-compliant design and FDA-approved seals

- Flexible use with a wide range of media

- Easy integration into existing process control systems

- Durable, low-maintenance and reliable signal detection