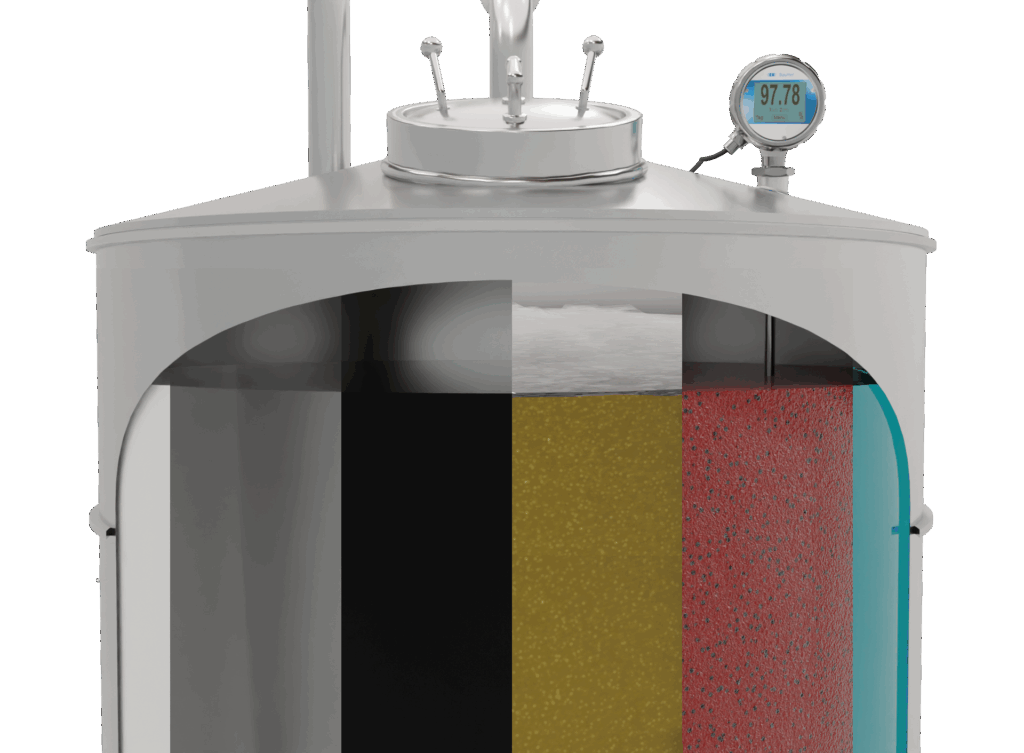

They do actually exist: unproblematic media, where you can easily measure the level with float sensors, radar sensors, or by hydrostatic means. However, plant operators, maintenance personnel, and production managers often have to deal with problematic media that make reliable level measurement a challenge. In many cases, these are paste, adhesive, or foaming media with low conductivity or media interspersed with foreign bodies.

For these demanding applications, the different sensor principles have their respective weaknesses:

- Radar sensors and ultrasonic sensors work with foaming media only to a limited extent. Also, they are not suitable for short measuring heights.

- Float switches easily become fouled with adhesive media. This could disable the moving parts of the mechanics. There is another disadvantage with changing viscosities, since floats float differently on different densities. In this case, the floats may have to be adjusted to always indicate the correct level. Float switches also inherently contain crevices and dead spaces where bacteria can develop and multiply. This is an exclusion criterion, especially in the food sector.

- Optical level sensors are usually not very accurate and can be affected by contamination or reflective surfaces.

- Capacitive sensors usually have to be calibrated for the corresponding medium.

- With hydrostatic measurement, deposits and residues in the tank can significantly affect the measurement. Even temperature jumps have an effect on the pressure and can falsify the level measurement.

- Potentiometric level sensors: This measuring principle cannot measure liquids with very low conductivity. Until now, the minimum conductivity for potentiometric measurements was 50 microsiemens/cm (Baumer level sensor LSP).

CombiLevel PLP70: The end of compromise

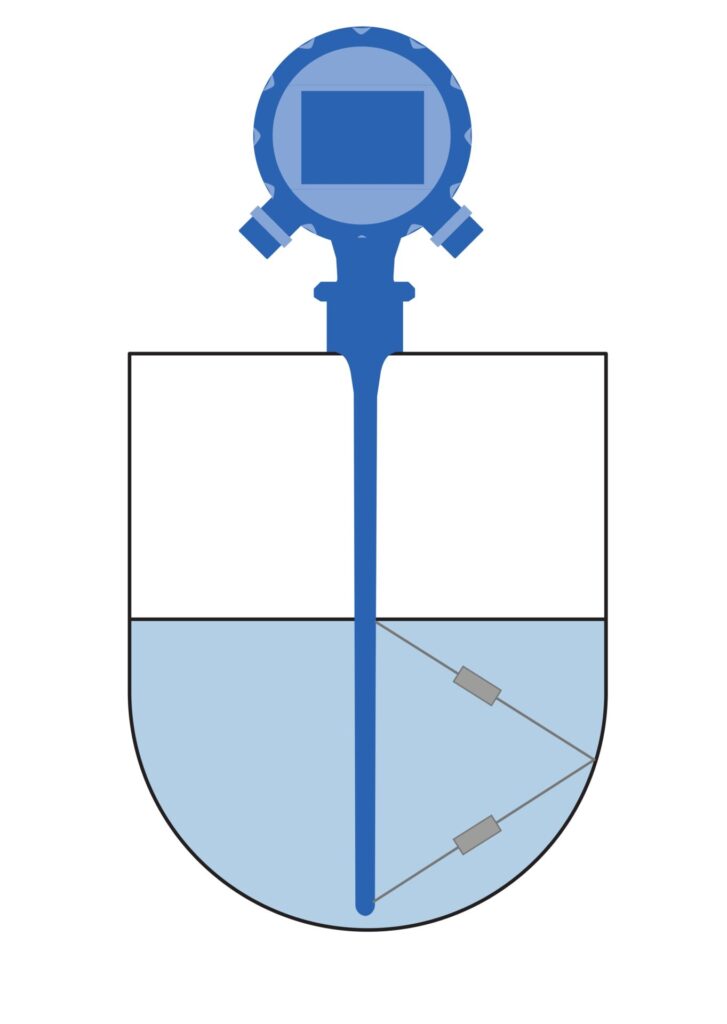

Challenging media pose a difficult task for users when it comes to level measurement, as the search for the right measuring principle does not always lead to satisfactory results. With the Baumer CombiLevel PLP70, some applications are now much easier. For with this latest innovation, Baumer has eliminated the previous weak point of potentiometric level sensors: the minimum conductivity of 50 microsiemens/cm. By designing the CombiLevel PLP70, the developers have created a sensor for which a conductivity of just 5 microsiemens/cm is sufficient for precise level measurement. 5 microsiemens/cm corresponds to the conductivity of distilled water. Even process water is often above this value, depending on the application, so that the PLP70 can reliably indicate the level even with these less conductive media. The PLP70 measures the level potentiometrically, i.e. via the change in voltage, which changes with the level. The higher the level, the greater the voltage.

As a result, the PLP70 combines many of the strengths of the different sensor principles:

- It is unaffected by foam and buildup.

- The PLP70 is suitable for a wide variety of media, and media changes are possible without parameterization.

- The floatless principle means that no moving parts can stick together.

- Deposits and residues in the tank have no influence on the measurement result.

- The PLP 70 has a very short response time.

- The new Baumer level sensor is easy to clean thanks to its compact and hygienic measuring rod. The hygienic design without gaps and dead spaces makes it difficult for bacteria to form.

The combination of floatless measuring principle, insensitivity to foam and buildup, and low minimum conductivity makes the PLP70 a flexible all-rounder for many demanding applications in small tanks. It is suitable for applications in metallic, non-metallic and pressurized tanks with short measuring heights between 200 mm and 3000 mm. It also works in non-metallic tanks in combination with an easy-to-install reference electrode. As media changes do not require any adjustments, it is ideal for high variety of types and frequently changing media. As a result, the PLP70 offers maximum flexibility and plant efficiency.

Well suited for cleaning systems and ring fillers

The potential fields of application for potentiometric level measurement are cleaning systems for components, racks, or tools. The PLP70 is temperature stable up to 115 degrees Celsius continuously and up to 130 degrees Celsius for a maximum of 30 minutes. The new Baumer level sensor is ideally suited for ring fillers with frequent media changes and short fill heights in the food sector.

Info box: PLP70 application areas

Industrial Fluid Handling

- Process tanks

- Cleaning systems

- Filter system

- Agricultural machinery

- Water treatment plants

Food & beverage

- Process tanks

- Storage and buffer tanks

- Filling systems

- Filter systems

- Storage tanks

- Cleaning systems (CIP)