Cleaning is carried out as part of proven and standardised CIP (Cleaning in Place) processes that ensure the hygienic integrity of the production system. Concentrated acids or alkalis are often used for this purpose. These are stored in dedicated tanks and diluted to the required concentration during the cleaning cycle directly within the production system.

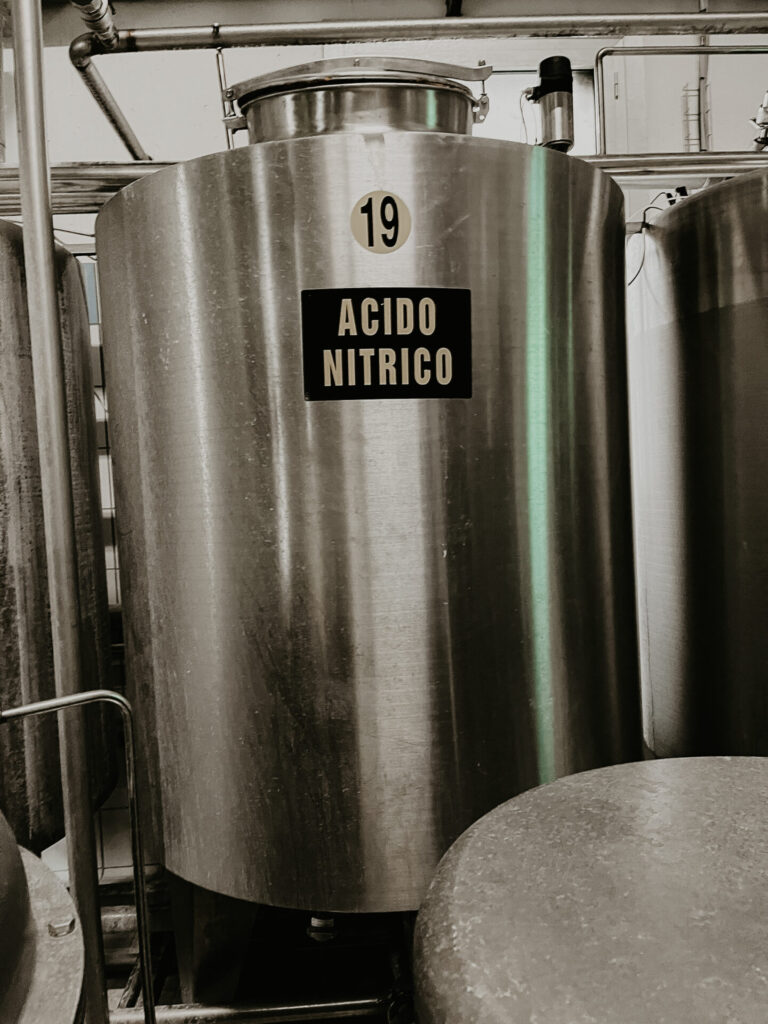

For safe storage, nitric acid is kept in corrosion-resistant stainless steel tanks – ensuring long-term stability and reliable availability within the CIP system.

The focus of this application is on the use of chemically resistant materials in all installed sensors to ensure long-term functional reliability and maximum process safety under demanding conditions.

For reliable continuous and point level measurement, the following UWT sensor solutions are used:

NivoRadar® NR 7200:Continuously measures the filling level in the main tank – non-contact, precise and maintenance-free. Even under conditions with vapour formation and aggressive media, the 80 GHz radar delivers reliable measurement results. Due to the vapour exposure from highly concentrated nitric acid – even without reaction with other substances – a PVDF version is used in this application. This ensures maximum chemical resistance and long-term operational reliability.

Vibranivo® VN 7130: In this application, it functions as a full detector and reliably monitors the upper level limit. Thanks to a 300 mm pipe extension, the vibrating fork is positioned exactly at the maximum fill level – ensuring accurate detection of the acid level and providing a dependable shutdown safeguard.

Vibranivo® VN 7120 (compact version): Reliably detects the lower limit in the stainless steel tank’s drain line, protecting against dry run or unintended emptying during the flushing process. The sensor is unaffected by flow, turbulence or air bubbles – ensuring consistent and precise measurements, even under demanding process conditions.

Material resistance for aggressive media:

All wetted parts of the sensors are made from chemically resistant materials such as PTFE, PVDF, FKM, FFKM and stainless steel 1.4404 / 316L. This makes them ideally suited for long-term use with highly concentrated nitric acid.

For the dairy plant, this means reliable descaling with consistent process quality, minimal maintenance effort and high operational safety – thanks to robust measurement technology from UWT. LEVEL. UP TO THE MAX.