Advantages of IBC storage

• Direct connection to dosing pumps without manual transfer

• Dosing station ensures safe dilution and controlled feeding

• Easy handling: empty IBCs are quickly replaced and returned to the supplier

• UN-approved design with tight screw caps and steel cages – compliant with all requirements for the transport and storage of corrosive media such as NaOH

For smaller plants, this eliminates the need for large stationary tanks and provides a flexible, space-saving and safe solution.

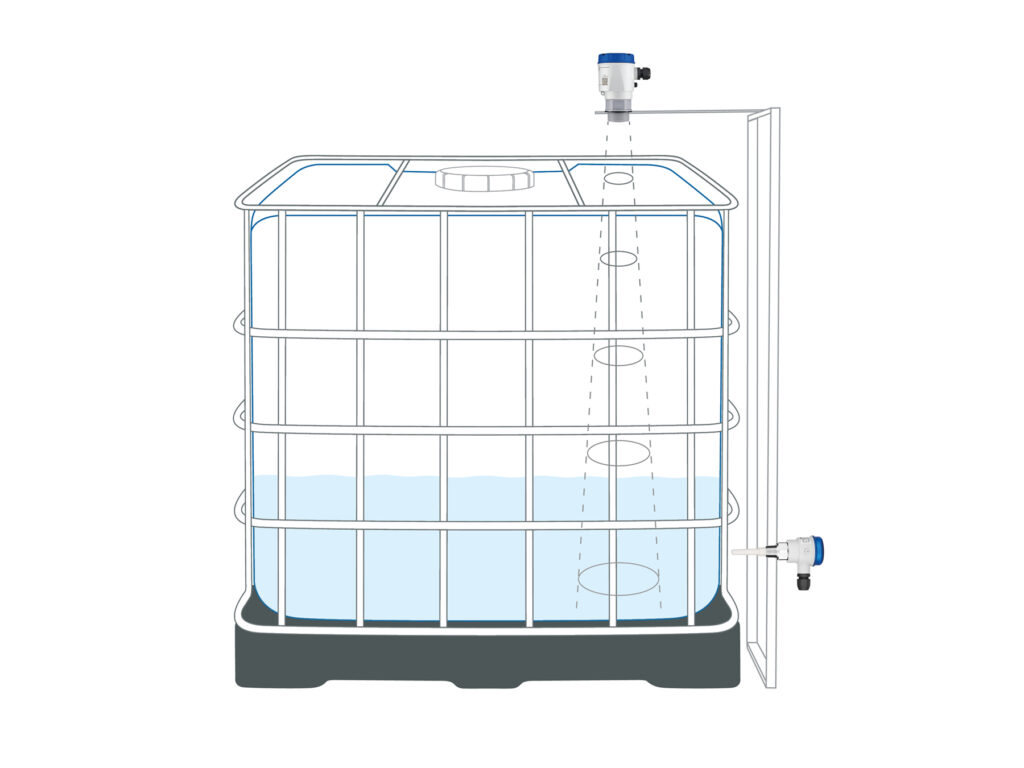

Accurate measurement from outside

At the storage location, a stationary measuring point was installed. UWT sensors monitor the IBC filling level entirely from the outside – no contact with the aggressive medium required.

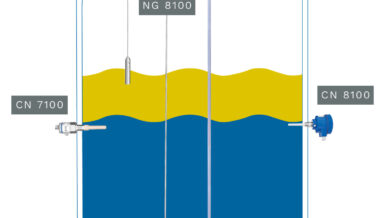

Continuous level measurement

The NivoRadar® NR 7100, a compact free-radiating 80 GHz FMCW radar sensor, is mounted vertically above the IBC. With its narrow 8° beam angle, it provides highly precise and reliable measurement – directly through the plastic tank wall.

Point level detection

As an additional safeguard, the Capanivo® CN 7120 capacitive sensor is installed externally at a low level next to the IBC, providing reliable empty detection. It reliably signals when the container is about to run empty and needs replacing. The sensitivity can be adjusted directly on the device via a potentiometer, making the sensor adaptable for use with different liquids.

External mounting protects sensors and ensures flexibility

Because the sensors are mounted outside the IBC, they never come into direct contact with the strongly caustic soda. This protection significantly extends sensor lifetime and ensures long-term operational safety. At the same time, the system remains highly flexible: when exchanging IBCs, different cleaning or disinfecting agents can be used without having to reposition or replace the instrumentation.

This case study demonstrates how the combination of UWT radar and capacitive level sensors combines safety and flexibility in chemical handling. External installation keeps the instrumentation fully protected, while the easy exchange of standardized IBC tanks supports the flexible use of various cleaning and disinfecting agents in hygienic dairy production.