Ultrasonic Level Technology, Proven Technology and Continually Refined

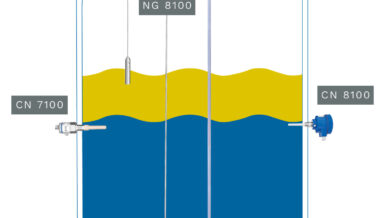

Ultrasonic level measurement has long been a cornerstone technology in water and wastewater treatment. With non-contact operation (also known as through air), intuitive setup, and robust performance across a wide range of conditions, ultrasonic sensors and controllers are widely adopted for level and open-channel flow monitoring. Their ability to operate reliably in environments with changing temperatures, humidity, and occasional submergence has made them especially well-suited to applications such as wet wells, lift stations, filter beds, clarifiers, and chemical tanks.

Rather than remaining static, level and pump controllers using ultrasonic technology have progressed in ways that enhance both accuracy and usability. Modern systems incorporate temperature compensation with their sensors, advanced signal processing, and digital filtering, thereby allowing for high-resolution measurements even in dynamic conditions. The result is instrumentation that offers not just stability, but clarity, even in the face of condensation, buildup, or challenging weather.

Designed for demanding level applications

Water and wastewater treatment systems often operate in environments where durability is just as important as precision. Ultrasonic transducers, by their non-contact nature and inherent mechanical action, remain low maintenance and self-cleaning. In extreme conditions such as flooding or overflow, advanced systems reliably detect abnormal states and maintain dependable readings and ensuring that operators are alerted when it matters most.

As processes evolve, so do expectations around connectivity, control, and remote access. Ultrasonic level controllers have steadily expanded in capability, enabling web-based configuration and real-time diagnostics across a range of industrial communication standards. With optional communication cards supporting protocols such as Ethernet/IP, PROFINET, Modbus TCP, and legacy fieldbus systems, these controllers demonstrate alignment with the digital transformation many facilities are pursuing. This level of integration, often overlooked in sensor selection, enables ultrasonic systems to adapt to both existing infrastructure and future upgrades without costly retrofits.

A platform that thinks beyond measurement

Ultrasonic solutions do more than report level; they orchestrate the process. When robust ultrasonic transducers are paired with an intelligent controller, these systems deliver not just visibility, but precise control of pumps, alarms, and flow routines. Built-in features for energy savings, diagnostic reporting, advanced pump duty cycling, discrete inputs, and even firmware updates ensure that the system not only keeps pace with daily operations but actively optimizes them as the evolution continues.

This is especially true in multi-pump environments, or where compliance and data logging are critical. The ability to program complex behavior such as differential level, backup logic, or economy pumping routines at the controller level gives operators a powerful toolkit, without the need for a PLC or specialized programming expertise. And with onboard web capabilities, secure browser-based access now makes it easier to configure both simple and complex configurations using intuitive wizards, from anywhere on the network or directly at the instrument.

Application fit over technical trends

When selecting instrumentation for water and wastewater applications, technology choice should be guided by the specific needs of the process and not simply by the availability of newer solutions that are often promoted as the only option i.e. radar technology. Ultrasonic technology continues to be a top performer in the environments where it has long been deployed. It offers a compelling balance of reliability, accuracy, and total cost of ownership. It has been designed and evolved with the needs of the water market in mind.

Importantly, it remains one of the few technologies that has achieved some of the industry’s highest flow measurement standards, such as MCERTS Class 1 certification, which requires a resolution of 1 mm. Achieving this level of performance underscores how refined and capable ultrasonic level controllers using technology have become over time.

Conclusion

Ultrasonic level measurement has earned its reputation in the water and wastewater industry through consistent, intelligent performance. What was once seen as a basic sensing technology has matured into a robust, digital-ready platform capable of handling today’s process challenges while paving the way for tomorrow’s process automation needs.

Rather than being eclipsed by trendier alternatives that narrowly focus on a single task, such as basic level measurement via 4–20 mA or HART, ultrasonic systems have evolved by becoming more integrated, adaptable, and aligned with real-world challenges. For those who value a solution that balances performance with practicality, and intelligence with ease of use, ultrasonic level measurement with advanced controllers continues to be a trusted and forward-looking choice.