Reliable Results with FMCW Radar

Non-contact radar sensors measure levels accurately and without physical contact. The transmitted signal is varied across a specific frequency range. The difference between the transmitted and echo signals determines the travel time, which provides the exact fill level. This technology works well for both bulk solids and liquids, even in conditions with dust, steam, condensation, buildup, or fluctuating temperatures. Internal installations such as agitators are automatically compensated for, ensuring consistent measurement results at all times.

NivoRadar® NR 3000 for Solids

The NR 3000 series features flexible configuration options and robust designs for solids in silos, hoppers, and process vessels. Its radar technology penetrates dust and buildup, delivering reliable results even in tough conditions. In addition to plastic horn and threaded antenna options, the NR 3300 in the Allround-Pro version is available with a stainless steel adjustable flange (316L), automatic lens cleaning, and an optional high-temperature standpipe for processes up to +1200 °C / +2192 °F.

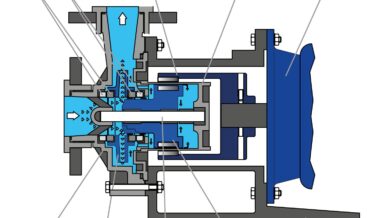

NivoRadar® NR 8000 for All Types of Liquids

The NR 8000 series has been designed for a wide range of liquids, including water, beverages, oils, chemicals and media requiring strict hygiene standards. It offers versions with plastic horn antenna, threaded connection, PTFE-encapsulated antenna for chemical resistance, and hygienic designs suitable for CIP/SIP processes. Additionally, the series includes a horn antenna model built for extreme process conditions, capable of withstanding pressures up to 160 bar / 2,320 psi and temperatures up to +450 °C / +842 °F.

Versatile Designs for Precise Level Measurement in Solids and Liquids

UWT thus offers a broad product range – from economical basic versions to Allround-Pro models for extreme processes. Additionally, the standard models can be easily configured to meet specific requirements. Users benefit from the highest measurement accuracy, a wide variety of design options, and straightforward commissioning via plug-on display, UWT LevelApp, or PACTware.