The Challenge

In a modern automotive plant, process water is generated continuously during component production and cleaning. This wastewater is collected in underground collection or drainage pits before being transferred by pump stations to the plant’s central wastewater treatment facility.

These pits are located beneath the production halls and are typically cylindrical concrete tanks about 4 to 6 meters deep. They temporarily hold contaminated water from cleaning stations, body pretreatment, or cooling circuits before it is treated or neutralized.

The environment places high demands on measurement technology: humidity, condensation and limited accessibility make accurate level detection difficult. Contact-based systems are often unsuitable or maintenance-intensive in such conditions – which is why non-contact radar technology is the preferred choice.

The Solution

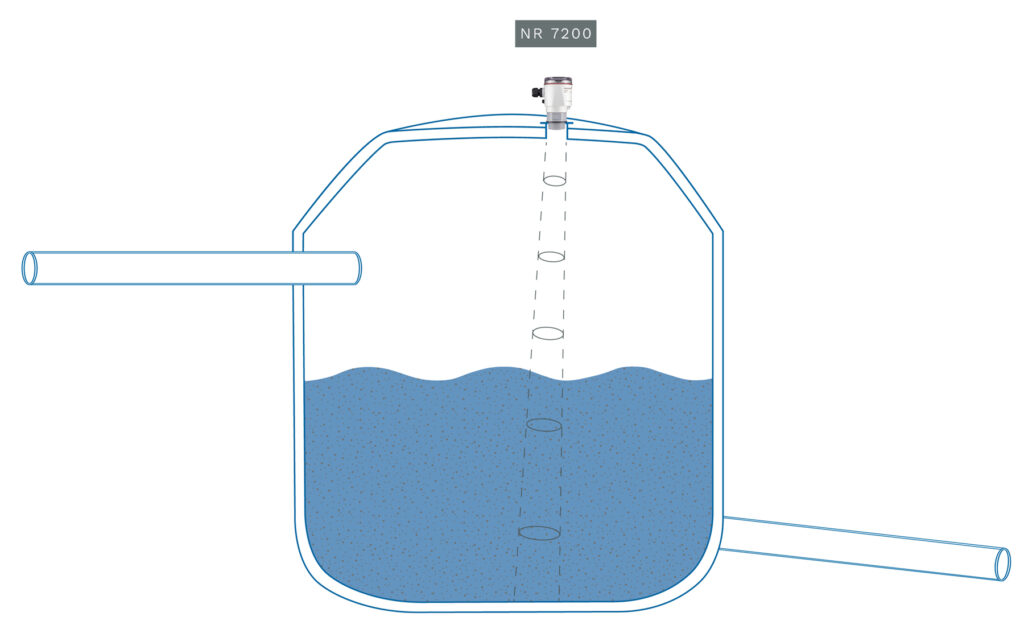

For this application, several UWT NivoRadar® NR 7200 sensors were installed. The project was implemented by UWT India, supporting the operator in selection, planning, and commissioning.

The radar sensors provide continuous level monitoring, control the pump operation, and ensure smooth system performance. Thanks to the non-contact 80 GHz FMCW radar technology, measurements remain accurate even when residues or thin oil films form on the liquid surface.

With a narrow 8° beam angle, the free-radiating radar delivers precise results even in confined shafts or where internal structures are present. Its compact design with a 1½” PVDF process connection enables easy installation in limited spaces.

The robust IP68/IP69 housing and ATEX Zone 2 approval ensure safe operation even in potentially explosive atmospheres. Zone 2 areas are defined as locations where explosive atmospheres of gases, vapours, or mists occur only rarely and for short periods, for example in the surroundings of tanks or facilities containing flammable liquids, unlike Zone 0 (constant) or Zone 1 (occasional).

Configuration and commissioning of the NR 7200 are handled conveniently via the UWT LevelApp using a smartphone or tablet. In this project, the devices were also equipped with an optional plug-on display, allowing permanent level monitoring both on-site and remotely via the app.

The Result

With the NivoRadar® NR 7200, the operator benefits from reliable, precise and maintenance-free level measurement that ensures the safe and efficient operation of the wastewater system. The rugged radar technology delivers continuous process monitoring, minimizes downtime, and reduces maintenance requirements across all underground pits.