In an ice cream production facility, raw milk is temporarily stored in an agitated tank before further processing. To ensure a stable process, both precise continuous level measurement and reliable point level detection are crucial. Additionally, agitators, limited installation space in the outlet pipe, and regular CIP/SIP cleaning cycles must be considered.

Process Challenges

- Strict hygiene standards for handling raw milk

- Regular cleaning using chemically demanding CIP/SIP processes

- Agitators in the tank that may influence measurement

- Limited space in the outlet pipe

UWT Solution Concept with Radar and Vibration Technology

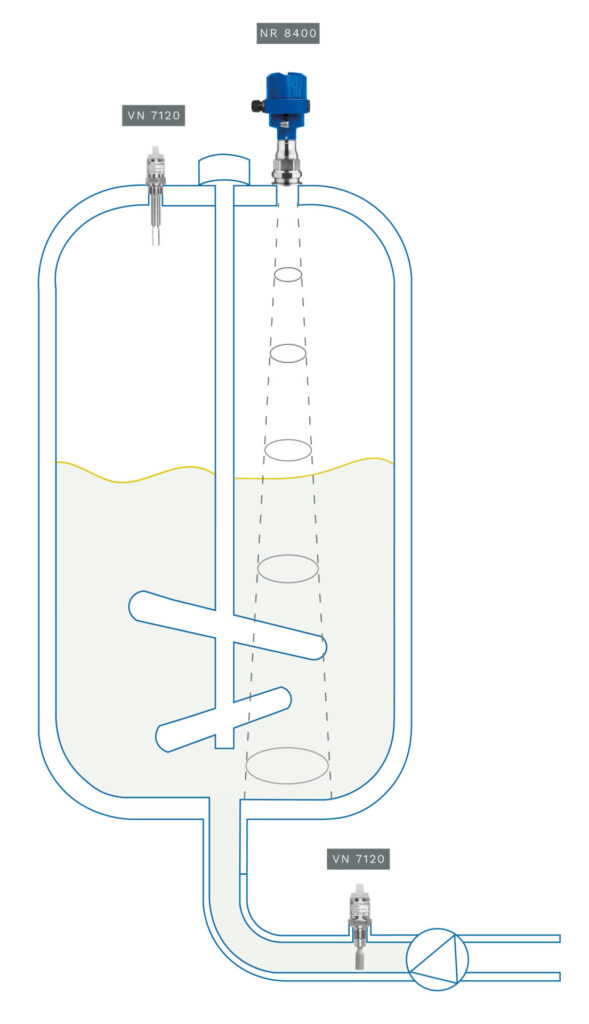

As the solution for this application, a NivoRadar® 8400 monitors the continuous level inside the tank. Additionally, a Vibranivo® VN 7120 with extension detects the maximum fill level, while another VN 7120 in compact design secures the outlet pipe to ensure controlled emptying.

The NivoRadar® 8400 is designed to meet the stringent standards of the food industry and complies with all relevant regulations such as EC 1935/2004 and FDA. Thanks to its hygienic design, it is also widely used in pharmaceutical applications. With a measuring accuracy of ± 1 mm, it provides precise and stable results, even with agitated surfaces caused by mixers.

Based on 80 GHz free-radiating radar technology, the sensor is perfectly suited for liquids such as milk. Agitator compensation can be easily configured via the UWT LevelApp, or alternatively through PACTware or the integrated display. The hygienic design with wetted parts made of stainless steel 1.4404 (316L), PEEK, and PTFE prevents buildup and allows efficient cleaning. The radar sensor operates reliably at process temperatures up to 150 °C, pressures up to +16 bar, and is protected up to IP68/Type 6P, making it ideal for CIP/SIP cleaning as well as high-pressure washdowns. A wide range of hygienic process connections such as Triclamp, Varinline, or DRD are available, and the device can be supplied with either aluminum or stainless steel housing.

Reliable Point Level Detection

Two Vibranivo® VN 7120 sensors are used for point level detection. In their hygienic stainless steel design with high surface finish, they are ideally suited for dairy processes.

- In the short version with 64 mm extension, the vibrating fork detects the maximum level in the tank and reliably prevents overfilling.

- In the compact version, the VN 7120 is installed in the outlet pipe, ensuring controlled emptying as well as protection of valves and pumps.

Especially in hygienic environments, the VN 7120 proves its strength with a robust, cleaning-friendly design:

- Housing and wetted parts made of stainless steel 1.4404

- High surface finish of Ra 3.2 µm (<0.8 µm) prevents buildup and ensures efficient cleaning

- Hygienic adapters such as Triclamp or flush-welded nozzles allow flexible integration into tanks and pipelines

- Protection classes up to IP69 guarantee resistance to moisture and high-pressure cleaning

- Reliable detection – unaffected by turbulence, foam, air bubbles, or buildup

Benefits for the Operator

- Precise measurement: Continuous and reliable level and point level detection

- Process reliability: Prevents overfilling, works consistently with agitators and turbulence, ensures controlled emptying, and protects valves and pumps

- Hygienic design: Stainless steel, PEEK, PTFE – compliant with EC 1935/2004 and FDA

- Cleaning-friendly: Compatible with CIP- and SIP for efficient processes

- Easy commissioning: Simple configuration via LevelApp, display, or PACTware

- Flexible: Multiple hygienic process connections for tanks and pipelines

- Maintenance-free: No calibration or readjustment needed for the medium

Project Data

- Medium: Raw milk

- Measuring range: up to 5 m

- Process temperature: < 80 °C

- Sensors:

- NivoRadar® NR 8400 featuring a hygienic antenna

- Vibranivo® VN 7120 in compact and extended versions

Customized Sensor Solutions for Maximum Process Safety

With this combination of radar and vibration technology, UWT meets the high standards of food production: hygienic, reliable, and efficient. At the same time, UWT customizes solutions to fit individual customer needs – whether through a wide range of configuration options for standard sensors or with custom-made special designs.