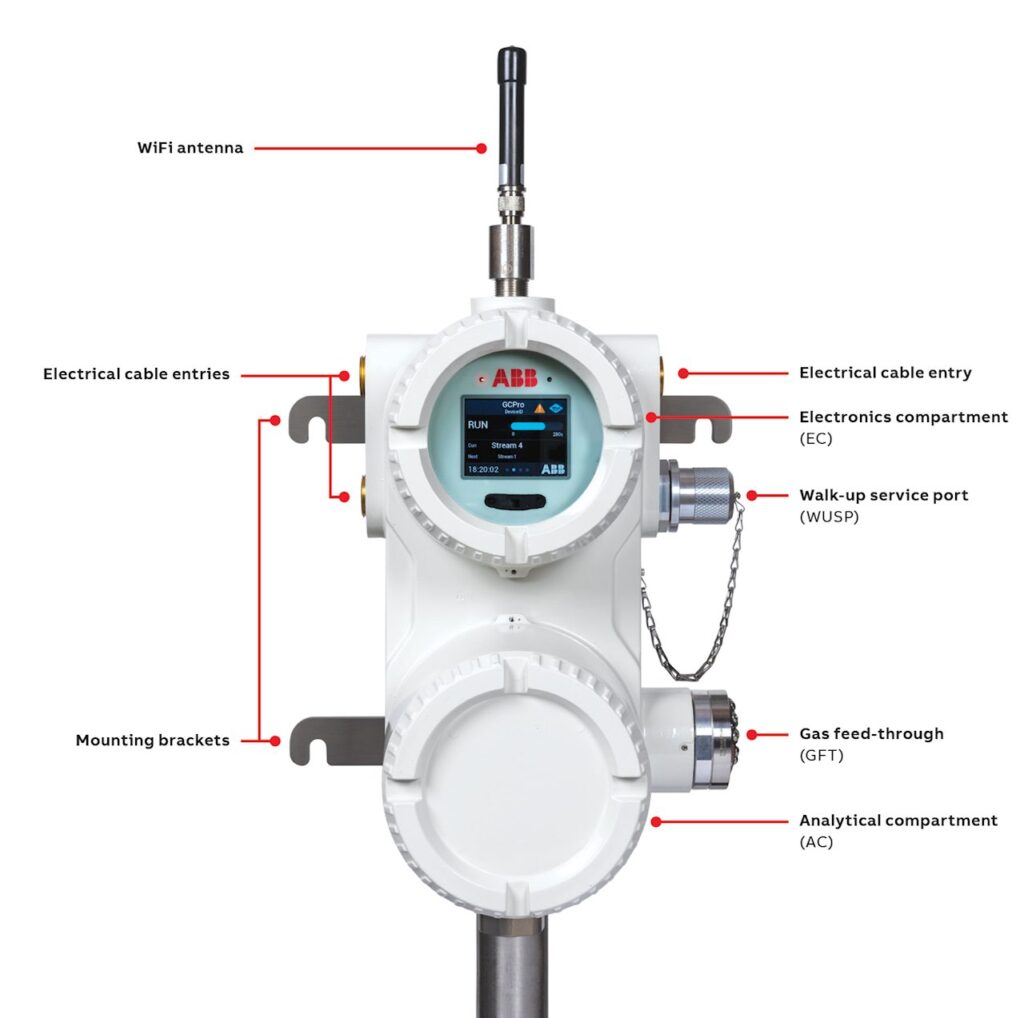

ABB has launched the GCP100 gas chromatograph setting a new standard in cybersecurity and real-time analysis of complex gas mixtures in the natural gas, biogas, oil and petrochemical industries. Part of the new GCPro series, the GCP100 supports plant operators with monitoring process stability and product quality in real-time. Integrating cybersecurity features, the GCP100 transforms traditional process analytics, providing operators with insights that enhance efficiency in a secure way.

The GCP100 is the first gas chromatograph (GC) with built-in cybersecurity and integrated WIFI on the market. Unlike other GCs on the market, it doesn’t need to connect to third-party devices, eliminating gaps in encryption and security. With all elements of encryption embedded into the GCP100 analyzer, confidential process data is more secure than ever before. Cybersecurity is crucial for gas chromatographs because these devices are often used in critical infrastructure sectors such as energy and environmental monitoring.

“ABB’s next-generation of gas chromatographs incorporates highly innovative advances in GC technology and digitalization,” said Jean-René Roy, Global Business Line Manager, ABB Measurement & Analytics. “We worked diligently to ensure the new GCPro series would become the benchmark industries rely on into the future – and that starts with today’s launch of the GCP100. For more than 60 years, ABB has been at the forefront of gas chromatograph technology, providing real-time gas analysis for the process industries.”

Created for extensive industry and application flexibility, the GCP100 will help industrial operators transform their process analytics with precision and accuracy, novel digital connectivity, low gas sample and carrier gas consumption as well as low energy consumption, making possible the continuous monitoring of systems without increasing the technical and maintenance burden on operators. Thanks to an extended 60°-100°C (140°-212°F) temperature range and 1 part per million (ppm) detection range with advanced modularity, the GCP100 covers a wider range of industries and applications.

Through advances in both hardware and software, including dynamic QR code capabilities and AI-powered features, the solution is designed to reduce maintenance-related downtime by up to 75 percent. With a 4-inch gesture-controlled display and patented modular design, the GCP100 sets a new industry standard in serviceability.

Integrated with ABB’s AI-driven My Measurement Assistant+ with ABB Ability™ Genix Copilot, operators can instantly access documentation, error codes, and spare parts information for streamlined diagnostics, predictive maintenance and condition monitoring.

Engineered for low-power consumption levels of 12 Watts, the GCP100 will support industrial operators on their energy-saving journey. In addition, smaller shelters and in some cases shelterless installations, with lower heating, ventilation and air conditioning costs, contribute to lower capital costs to make the GCP100 the GC with the lowest total cost of ownership in its class.