Background

Rayon is used in clothing, upholstery and drapery fabrics, as well as industrial applications. Regenerated cellulose fibers (also known as rayon fibers) are made by chemical modification of the cellulose contained in wood pulp, so that it can be dissolved and spun into fine fibers in a solution. Typical rayon fibers are viscose, cellulose acetate and Lyocell fibers. Lyocell fibers stand out from this group because they are smoother, stronger and have greater wet-strength.

Lyocell production

This is more straightforward than other regenerated fibers processes because it does not involve the formation of a chemical derivative. In this process, wood pulp is dissolved directly in an organic solvent N-methylmorpholine N-oxide (NMMO). At a temperature of 100 °C (212 °F), an aqueous solution of NMMO is a very effective solvent for cellulose.

The Lyocell Process starts by debarking and chipping wood, which is then mixed with an aqueous solution of NMMO to dissolve the cellulose. The concentration and temperature of the solution play a significant role in the process, e.g. if the water content is too high (above 15 %) cellulose will not dissolve. The solution is initially prepared to 50-60 % of NMMO and then concentrated by evaporation in a heated dissolving vessel to give a dope solution of composition NMMO:water:cellulose (about 76:10:14). The temperature is kept between 90 and 120 °C. After a filtration step, the dope solution moves on to dry-jet wet spinning where the solution is extruded through a spinneret to make filaments. The filaments are formed in an air gap before entering a spinning bath for complete coagulation. The spinning solution can be water or a very dilute solution of NMMO.

The fibers are then washed, dried, and cut to obtain the final Lyocell fibers. The coagulating liquid is purified and concentrated to recover the NMMO for reuse in the process, and the recovery rate can be up to 99.5 % of the solvent.

Instrumentation

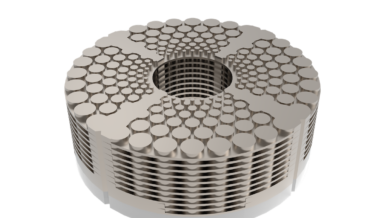

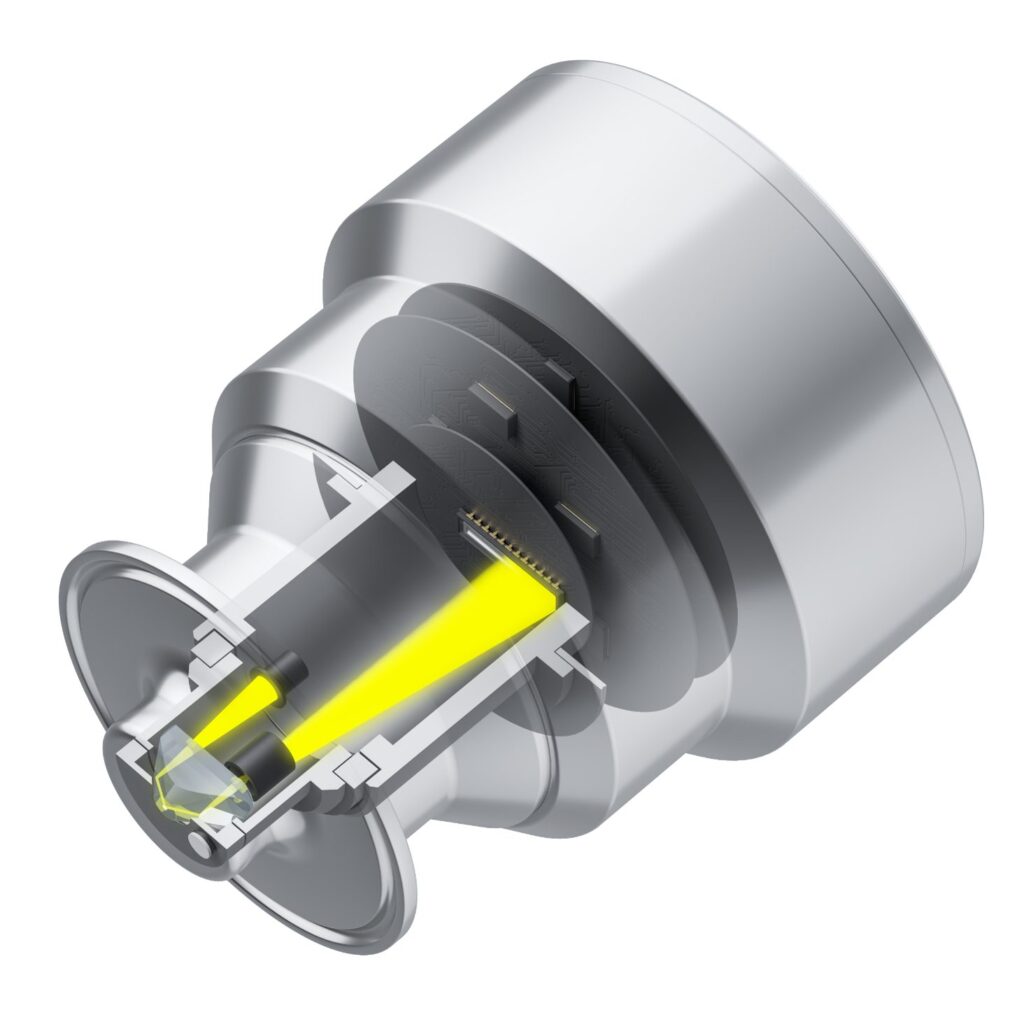

Vaisala Polaris™ PR53G Process Refractometer continuously monitors the concentration of the dope solution and the solvent at various stages of the process. This guarantees maximum productivity and high fiber quality.

The refractometer is installed in the dissolving tank outlet or directly in the dissolving tank where the cellulose is dissolved in NMMO while the solution is heated and concentrated. Changes in the refractive index value of the solution are used to monitor the dissolving process. This ensures that the correct concentration and complete cellulose dissolution is achieved, which is important because undissolved cellulose in the spinning dope results in poor spinnability and lower fiber quality.

During coagulation, the solvent diffuses out from the doping solution increasing the concentration of the bath. The PR53G continuously measures the spinning bath concentration as the fibers are produced. The refractometer’s signal is used to maintain the bath at the optimal concentration through the addition of water. NMMO is a very costly solvent, and its recovery is essential for the economic viability of the process.

The refractometer can also be installed in the solvent recovery phase to ensure the correct concentration, and to maximize the solvent recovery rate for later reuse in the process. Suitable for use in large and small pipes or directly in vessels, the Vaisala refractometer also provides Ethernet and 4-20 mA output signals for real-time and automated process control.

By enabling real-time control of the process, Vaisala’s inline process refractometers help improve efficiency and product quality, reduce waste, lower costs and enhance sustainability.

Keijo Pyörälä has been working at Vaisala (K-Patents) Liquid Measurements over 25 years in different positions from Product Management to Regional Sales Management and Global Business Development. Keijo has Master’s Degree in Chemical Engineering from Lappeenranta University of Technology and Executive Management Degree from Aalto University. He has been involved in number of global product and business development projects in different industry segments from food & beverages, pulp & paper, sugar & sweeteners to chemical & polymer and oil & gas all over the world. His specialty is process optimization with in-line process measurements, process efficiency and energy savings as well as quality improvement projects. Outside of work he enjoys playing golf and different outdoor activities with family.