All too frequent blockages from floating debris, plus fats, oils and greases had rendered the existing system unfit for purpose – with the NHS hospital facing constant downtime and the very costly need for tankers to remove the accumulated waste.

To address the issue with a far more robust solution that would be able to handle the high solids content, Dura Pump installed its latest offering, Velocity Sentinam, making use of two submersible Chopper Pumps, made by Landia. Designed with an external knife system that prevents solids from entering the pump’s casing, the Chopper Pump (invented by Landia in 1950) continuously reduces particle sizes.

‘We’ve always had very good experiences when using Landia’s pumps’

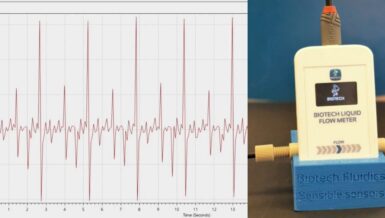

In addition to installing the new, much tougher 15kW pumps, Dura Pump upgraded the hospital’s effluent system with a new twin control panel that is fully integrated with the site Building Management System. The Dura Pump SenIQ panel includes inverters, a radar to measure the tank level, and a program to deliver intelligent pumping controls and warning alerts. Energy usage is also optimised as incoming flow rates are detected, controlling the output of the pump to match.

Dura Pump’s Technical Director, John Calder, said: “We’ve always had good experiences when using Landia’s pumps, so we were confident that these reliable tools could more than handle this challenging hospital application. Previously, when providing sewage solutions for prisons, we saw that not even shoes, jeans or bed sheets have been able to stop the Landia Chopper Pumps from running.”

With the new advanced software system designed by Dura Pump (who were established in 1976), the wastewater is pumped down to the base of the pumps, allowing them to skim all the floating debris off the surface. This can be repeated multiple times during the day.

By regularly skimming the tank, the level of fat buildup is significantly reduced. This is further enhanced by having an adjustable stop/start level that prevents the fat building up at one specific start/stop point.

The new system includes a monitoring and alert service, Dura Pump SenSync, which allows the system to be monitored remotely. If for any reason there is a fault with the pump, the pit level or the power, an instant message is sent to a nominated mobile number or email, informing the receiver of the problem, enabling them to take action before it causes a major issue.

Trends can be recognised over time, giving indication of wear on the pumps, valve issues and other performance related matters.

‘The hospital now operates far more smoothly, with downtime and disruption to daily operations minimised’

With full Building Management System (BMS) integration, it means the system operates with minimal manual input while providing the hospital with detailed performance insights.

Dura Pump’s Technical Director, John Calder, added: “No longer facing repeated pipe blockages, the hospital now operates far more smoothly, with downtime and disruption to daily operations minimised. Together with our bespoke system, the Landia Chopper Pumps play an important part in helping us deliver better cost management and energy savings for our customers.”