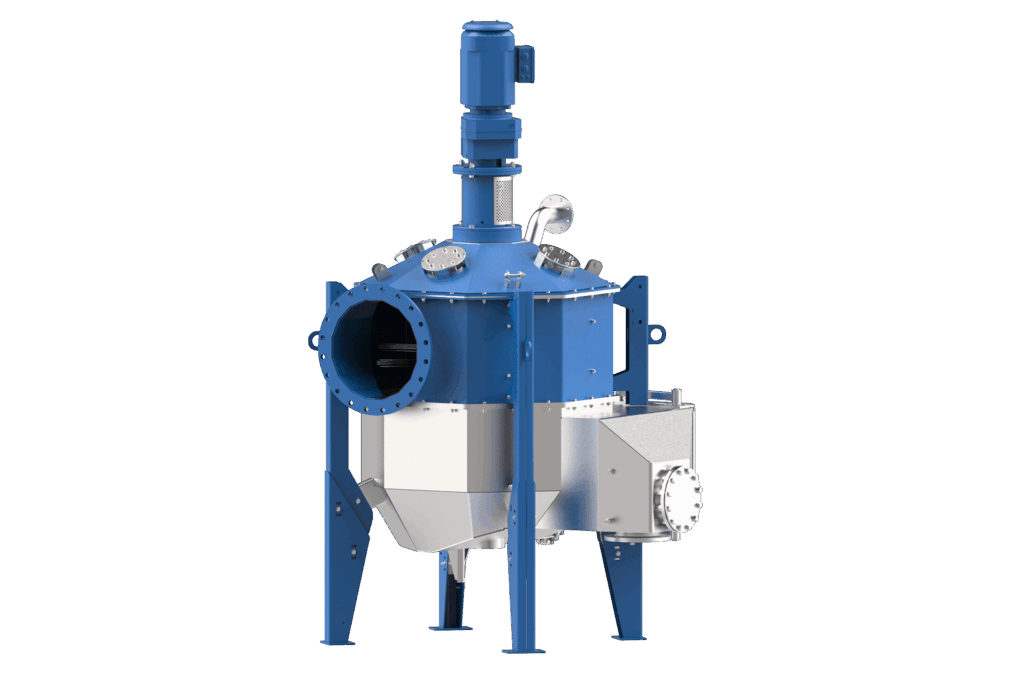

Optimising biogas production in an Anaerobic Digestion plant requires a perfect mix of liquid and dry feedstocks, the elimination of contaminants and solid bodies. The BIO-ROXX module from Wangen Pumps accelerates the fermentation process and increases the biogas yield by mixing solid and liquid phases to prepare the ideal inoculum, limiting air introduction to a minimum and removing solid bodies such as stones.

Installed downstream of the dry substrate hopper and the liquid feeder and before the fermenter, the Wangen Pumps BIO-ROXX module delivers a homogeneous substrate that increases the decomposition rate in the Anaerobic Digestion plant and speeds up gas production. Ideal for plant sizes of 1-10 MW, the BIO-ROXX module is a real asset in biomethane production, where high gas purity must be attained to meet the grid’s standards.

Improving biogas production

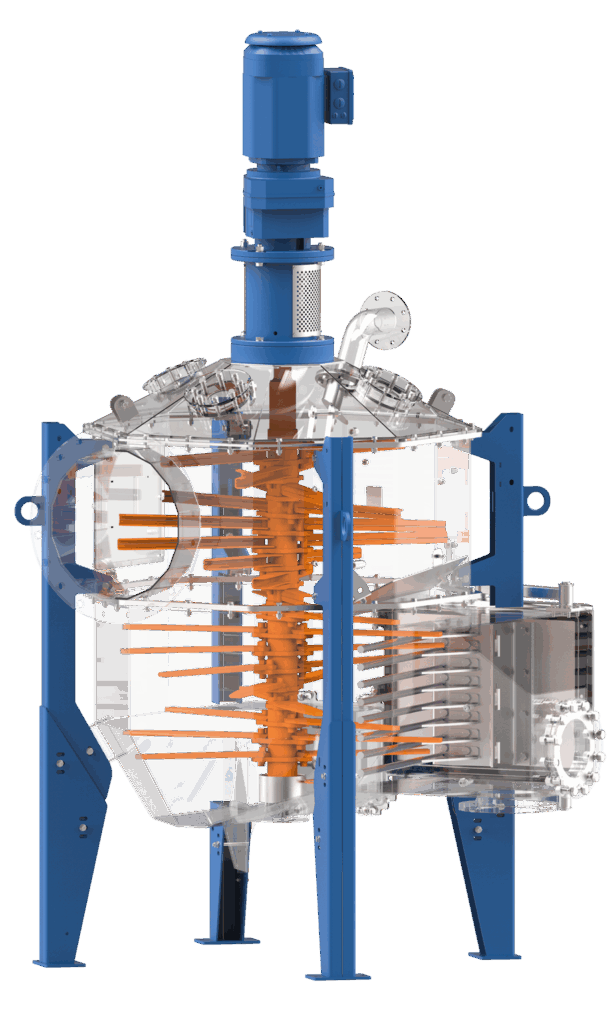

The BIO-ROXX features a sealed mixing chamber combined with a discharge pump below the fill line, so no air can enter and compromise the Anaerobic Digestion process. The unique configuration of the mixing rods and blades inside the chamber ensures that organic solids are evenly suspended and diluted, enabling the anaerobic bacteria to thrive and convert the organic materials to biogas. The mixing process enhances the efficiency of the fermenter by reducing viscosity and preventing the formation of a ‘float’ layer, which occurs when larger, fibrous solids accumulate as a crust on top. By preventing floats and assuring low viscosity levels, the BIO-ROXX maintains optimal gas production, reduces the energy consumption of mixers, and prevents damage to the paddles used for stirring the fermenter contents.

Reliable contaminant removal

Contaminants such as air can inhibit efficient biogas production. Stones, glass, wood, and bits of metal can settle at the base of a fermenter, reducing tank capacity over time. They can also cause damage, blockages, or breakages to pipelines, pumps, and other equipment.

Organic substrates with a dry content of up to 18% pass through the BIO-ROXX at a rate of more than 85 m3/h (22,484 gal/h). The dwell time in the unit enables solid contaminants to gravitate to the bottom of the mixing chamber, where they are caught in a trap and can be safely expelled. This prevents solid bodies from entering the fermenter and avoids the need to empty the digestion tanks to remove them or repair damage.

Highly adaptable technology

The Wangen Pumps BIO-ROXX can process organic materials from a wide variety of sources, including straw, maize stalks, whole-crop silage, manure, and food waste. Where fibrous materials of more than 30cm in length are common in the substrate, the BIO-ROXX is often used in conjunction with a hammer mill, an extruder or a macerator for improved operational productivity.

The BIO-ROXX, with its robust yet streamlined steel construction, is engineered to operate seamlessly in both mesophilic and thermophilic Anaerobic Digestion processes. It can deal with an inoculum of up to 18% dry matter content and is designed to perform reliably in harsh conditions, including high temperatures. Combined with its ability to handle a diverse and expanding range of substrates, these features make the BIO-ROXX an ideal choice for Anaerobic Digestion plants worldwide, offering a cutting-edge response to the evolving needs of the biogas industry.