Stadtentwässerung Kaiserslautern, the Kaiserslautern urban waste water management facility, reliably pumps valuable sewage sludge with a high dry matter content using the high-performance hopper feed pump KL-RUE supplied by WANGEN PUMPEN.

The purification of waste water is a technically complex process and the sewage treatment plants are therefore usually some of a municipality’s largest consumers of electricity. The example of the Kaiserslautern urban waste water management facility, an entity under public law, shows that it is possible to do things differently: after ten years of continuous energy optimisation and rebuilding measures, the energy-neutral sewage treatment plant has become a reality in the city.

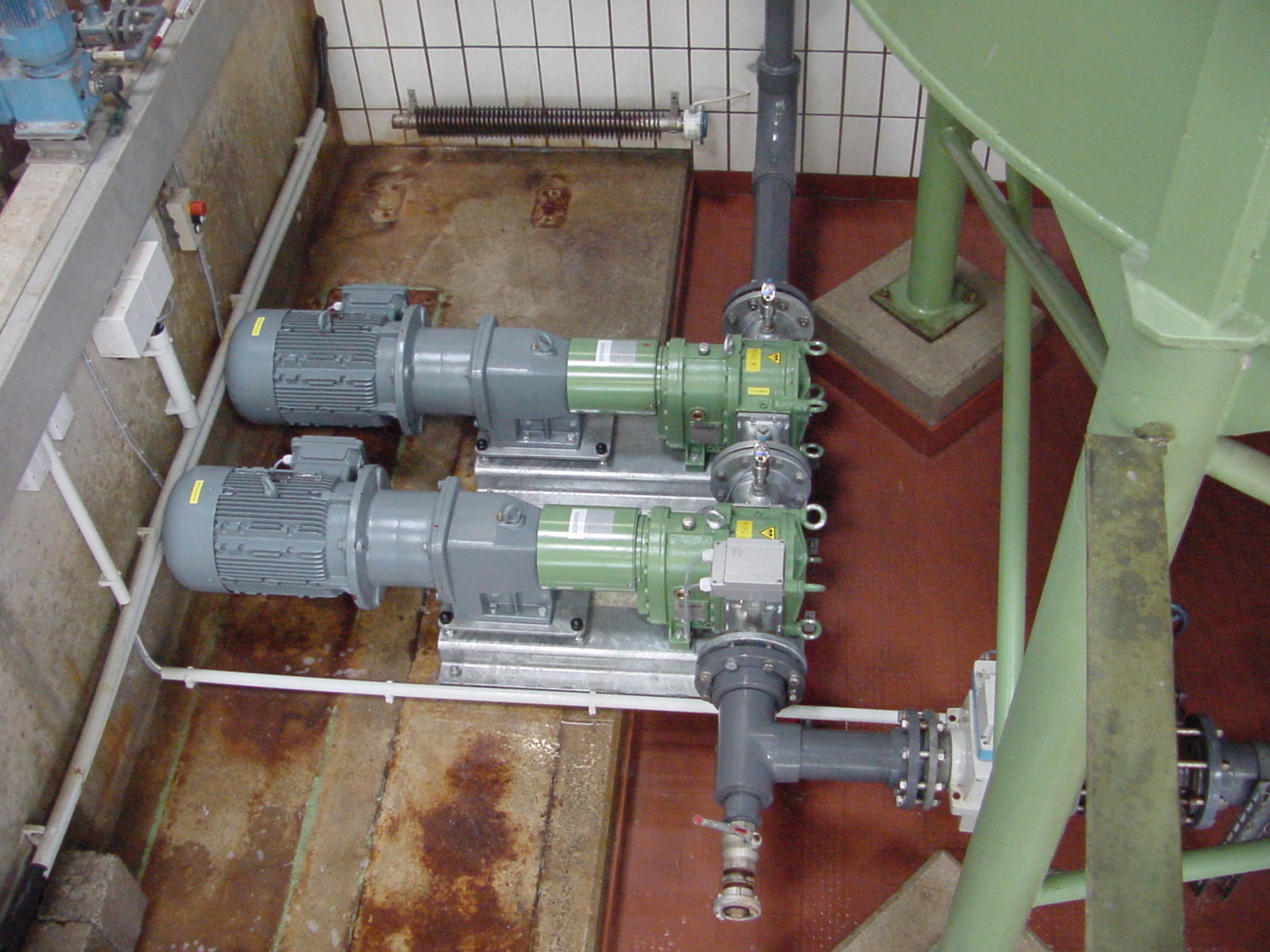

The updated system features two high-performance hopper feed pumps type KL-RUE supplied by WANGEN. These pumps reliably pump the dewatered sewage sludge with a dry matter content of 25 to 28% into the storage silos in an energy-saving manner. From there, the sludge is then loaded onto trucks and transported away for thermal recovery

Two satisfied customers at once

“We got a recommendation from a neighbouring clarification plant and then visited WANGEN PUMPEN at a trade fair,” reports Christian Forgheim, Plant Manager of the Kaiserslautern sewage treatment plant. The pumps we have used up to now have always caused problems, particularly due to their long design, high energy consumption, and longer downtimes during repairs. When one of the pumps had to be overhauled, the decision-makers opted instead to replace it, and purchase a new WANGEN PUMPEN model. The rotor and stator were renewed at the same time on the second pump, so that the operator could compare both types of pump with each other. The result showed the clear benefits of the WANGEN PUMP – two years later, the second pump was also replaced by a Wangen high-performance hopper feed pump.

The challenge: indentical performance with fewer downtimes

The seamless maintenance of the pump is an important criterion for the use of the WANGEN pumps in Kaiserslautern. The KL-RUE high-performance hopper feed pump meets this requirement, but also shortens downtimes due to the built-in quick-change unit (stator/rotor). “In the past, the pump was often unavailable for several days during maintenance work. The quick-change unit means that the pump is available again on the same day,” continues Christian Forgheim.

Technical data

KL-RUE high-performance hopper feed pumps are ideal for pumping dewatered sewage sludge with a high dry matter content of up to 45%, with a design based on a modular principle. This provides for maximum versatility and minimal stocking of spare parts.