An optimal solution for this problem is provided though special plant systems, in which the slurry is sustainably recycled.

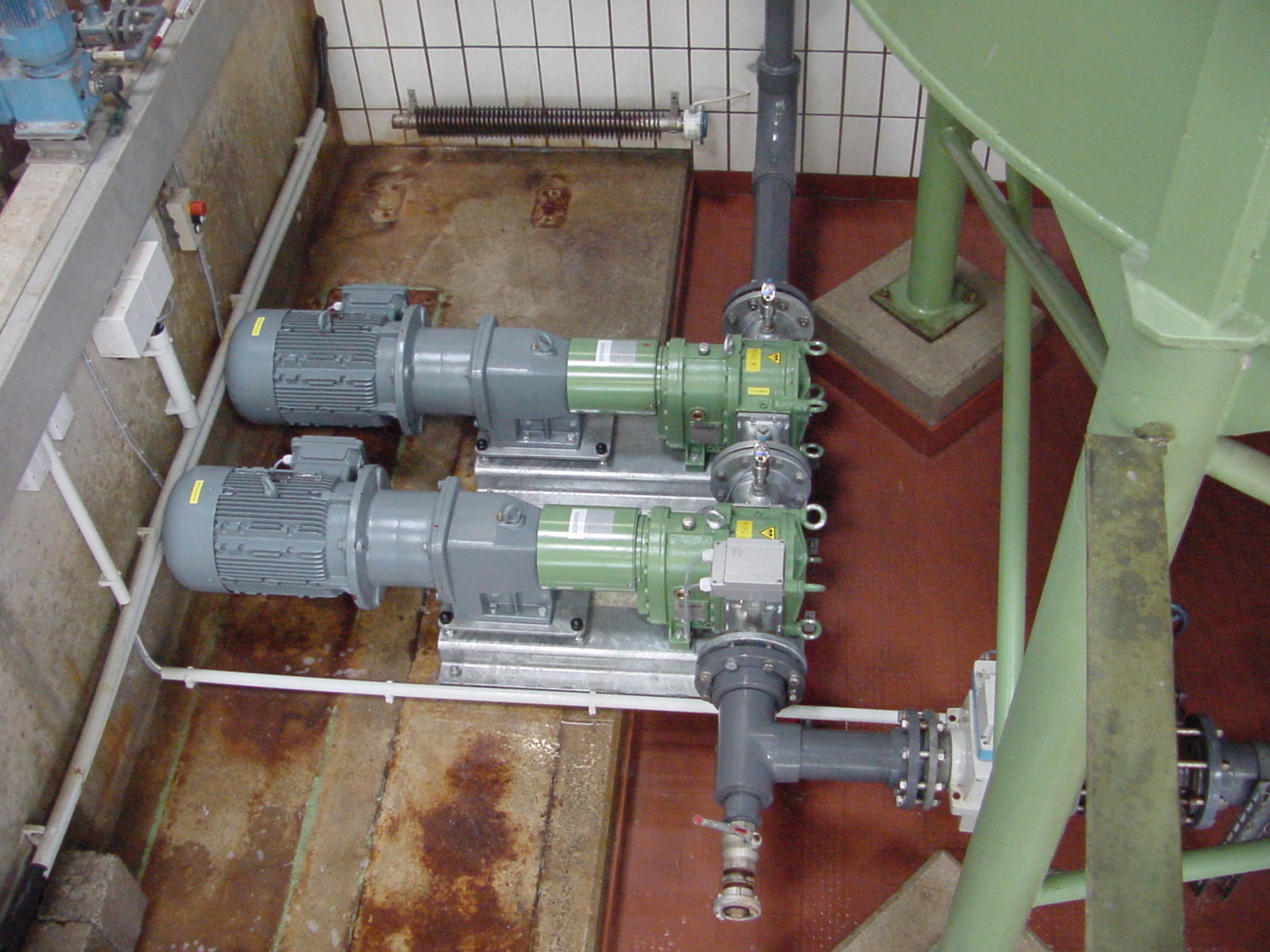

An important part of the treatment process is reverse osmosis, in which the ABEL high-pressure pump is used.

In this process, the previously recycled liquid, which consists of fermentation residues/slurry treatment, is transported at high pressure through the half-permeable membranes of the reverse osmosis system.

Through this technology, over 95% of the dissolved salts and substrates are separated and are therefore available again as fertilizer.

For more information about high pressure pumps please visit the ABEL website www.abelpumps.com