Sludge in wastewater systems, particularly thickened waste activated sludge (TWAS), is not only difficult to move due to its viscosity, but also contains solids and chemical residues that cause rapid wear in conventional pumps. Some facilities still rely on centrifugal pumps, only to face frequent clogs, excessive maintenance needs, and recurring downtime. This results in rising operational costs and loss of productivity—issues that progressive cavity pumps are specifically designed to overcome.

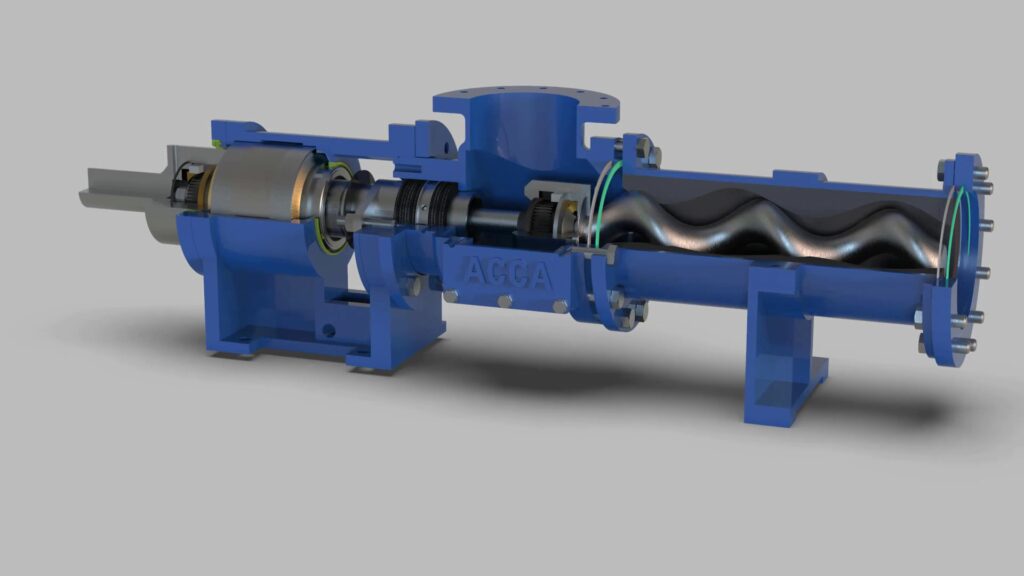

ACCA Pumps have quickly gained traction in the market as a high-quality, cost-effective alternative to major OEM brands. Progressive cavity pumps use a single-helix rotor and double-helix stator as standard configuration to create a continuous, low-pulsation flow that’s ideal for sludge movement. This gentle pumping action protects shear-sensitive materials while delivering steady, uninterrupted flow, even in high-solids or high-viscosity conditions.

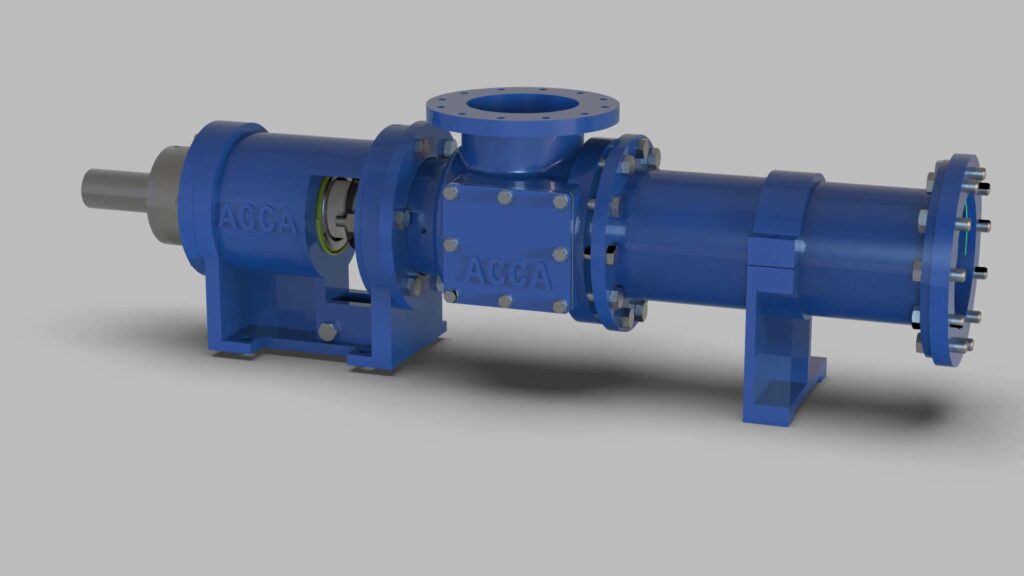

What sets ACCA apart is their focus on heavy-duty performance and practical engineering. Built from high-strength cast iron or stainless steel, ACCA pumps are equipped with chrome-plated tool steel rotors and stators available in a range of elastomers, including Buna-N, EPDM, and Viton, depending on the application. Their sealed gear joints reduce wear and contamination, while the modular pump design simplifies both maintenance and part replacement.

One of the most compelling benefits for plant operators is ACCA’s compatibility with existing pump systems. Their pumps are designed as direct-fit replacements for many pump OEM’s across all wastewater treatment plants. That means no need to modify baseplates, piping, or drives—plants can simply swap in an ACCA unit and be up and running in a matter of hours.

Plants switching to ACCA for their pumps and parts replacement also reduced its annual maintenance budget by 40% thanks to lower part costs and fewer labor hours.

ACCA offers a range of models designed to handle sludge of varying thickness and volume. There’s a solution for nearly every sludge application. With strong field performance, ease of installation, and budget-friendly operation, it’s no surprise that more facilities are making the switch to ACCA.In conclusion, ACCA Progressive Cavity Pumps are redefining sludge handling across wastewater and industrial settings. With dependable construction, low-maintenance operation, and direct-fit convenience, ACCA pumps offer a smarter, more economical way to keep sludge flowing and systems running at peak efficiency.