As the food industry intensifies its focus on sustainability and operational efficiency, cutting costs has become a top priority for many organizations. With growing pressure to streamline operations and reduce environmental impact, companies are seeking innovative solutions that enhance productivity and align with their commitment to sustainable practices. In this evolving landscape, the demand for cost-effective, efficient, and eco-friendly by-product management has never been greater.

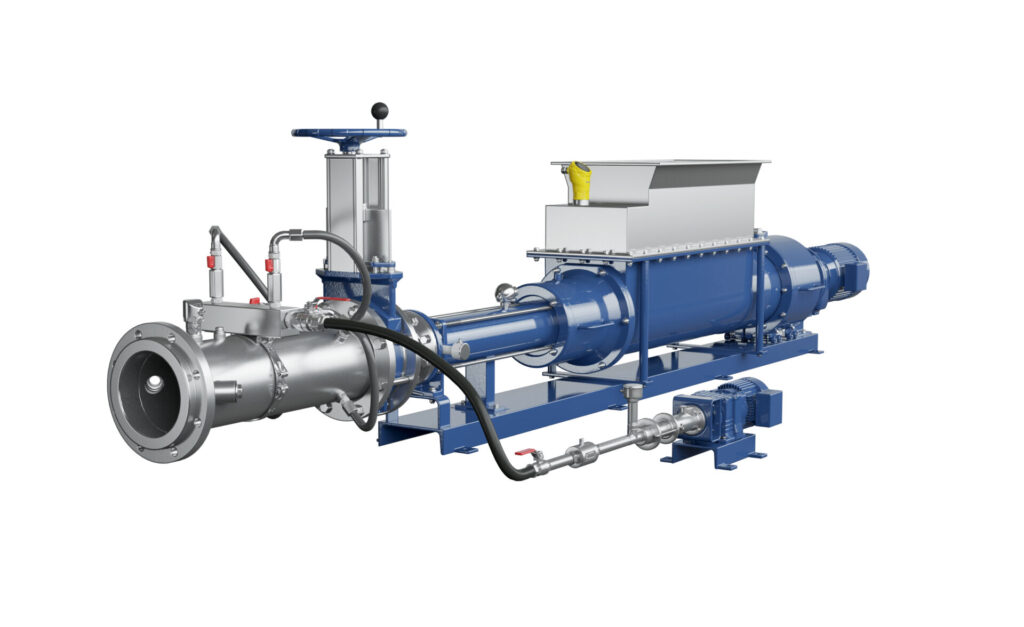

In the fast-paced world of food and beverage production, effective waste management is crucial yet challenging. Facilities often struggle with outdated mechanical conveyors, which are not only expensive but also energy-inefficient and complex to maintain. They are also cumbersome when dealing with long distances, elevation changes, and directional shifts, making them less suitable for modern processing needs. To make matters worse, manual handling by-products carries the risk of contamination, unpleasant odors and safety hazards that compromise cleanliness and efficiency. Pump solutions specialist SEEPEX now introduces SAI for food waste handling. SAI is a solution that the pump experts say addresses these critical issues head on.

SAI offers a new approach to overcoming these obstacles. The system excels in energy efficiency, providing a marked improvement over mechanical conveyors. By employing a closed piping system, SAI significantly reduces both energy consumption and maintenance requirements. This design not only enhances operational safety but also improves cleanliness by eliminating the need for odor extraction and emission controls.

One of the standout features of SAI is its versatility in handling a wide range of semi-solid and high-viscosity food by-products. Whether it is coffee grounds, tea leaves, mustard husks, or other challenging residues, SAI manages these materials effortlessly. This adaptability makes it an ideal solution for food and beverage operations, accommodating diverse types of by-products with ease.

Cost-effectiveness is another key benefit of SAI. With reasonable upfront costs enabling a quick return on investment, it is a financially sound choice for facilities. The system’s low-pressure pipeline not only reduces installation costs but also extends the equipment’s lifespan, ensuring long-term savings and reliability.

SAI’s ability to transport food waste over hundreds of meters, including changes in direction and elevation, eliminates the need for bulky conveyor structures. This capability simplifies construction and reduces associated costs, making it an efficient solution for complex processing environments.

SEEPEX’s innovative Rotor Joint Access (RJA) and Drive Joint Access (DJA) technologies streamline maintenance, minimizing downtime and reducing operational costs. Rotor Joint Access (RJA) features a sliding casing over the stator, providing quick and effortless access to the rotor-side joint. This design allows for easy maintenance without the need to dismantle the discharge pipework, pressure branch or stator, ensuring seamless operations.

Drive Joint Access (DJA) offers similarly efficient maintenance by enabling rapid access to the drive-side joint. The sliding casing allows for quick replacement of the coupling rod and mechanical seal without disassembling the hopper and extension hoppers if fitted, significantly simplifying upkeep in demanding applications. By integrating these advancements, SEEPEX enhances pump reliability and efficiency, making maintenance faster, easier, and more cost-effective.

SAI enhances sustainability by efficiently transporting dewatered food waste, conserving process water, and supporting oil-free compressors for by-product reuse, such as animal feed. Aligned with circular economy principles, the system helps reduce the plant’s environmental footprint, particularly by lowering energy consumption. Its proven energy efficiency may qualify for government or local authority subsidies*, which support energy-intensive industries in transitioning to a low-carbon economy.

SAI represents more than just a technological advancement; it is a transformative solution for food and beverage waste management. By addressing the core challenges of cost, safety, cleanliness and environmental impact, SAI provides a comprehensive and innovative approach to managing food waste.

Food and beverage industry professionals are invited to visit SEEPEX’s fully operational SAI test facility at its headquarters in Bottrop, Germany. This allows companies to observe the system in action while discussing specific application requirements. Alternatively, SEEPEX experts can arrange on-site evaluations to assess operational needs and tailor the system to individual processing challenges.

*Availability of subsidies varies by country and should be verified by the customer.